生产线送料机器人机械手设计

无需注册登录,支付后按照提示操作即可获取该资料.

生产线送料机器人机械手设计(论文说明书12900字,cad图纸8张)

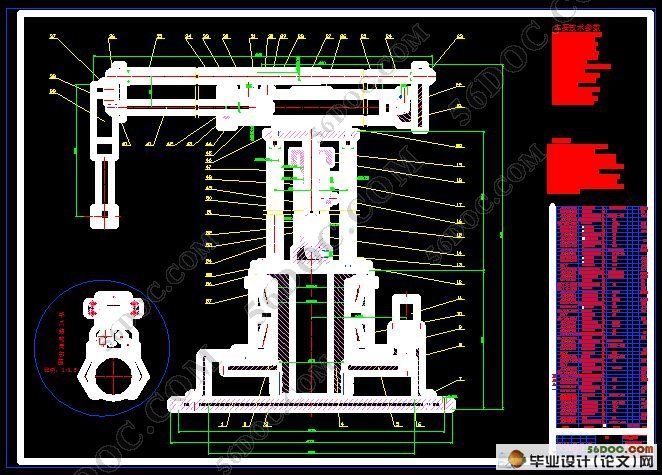

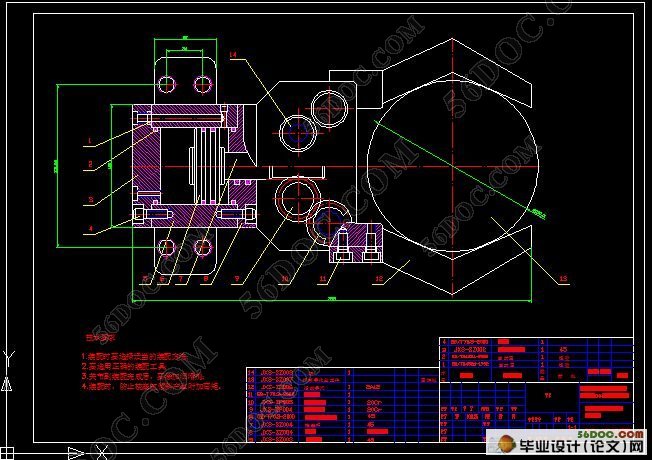

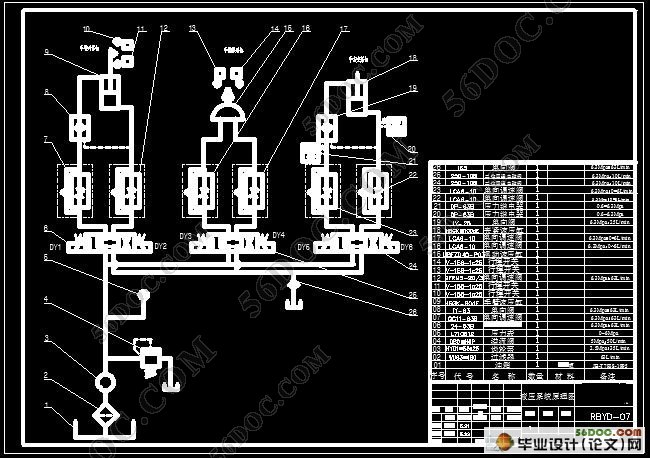

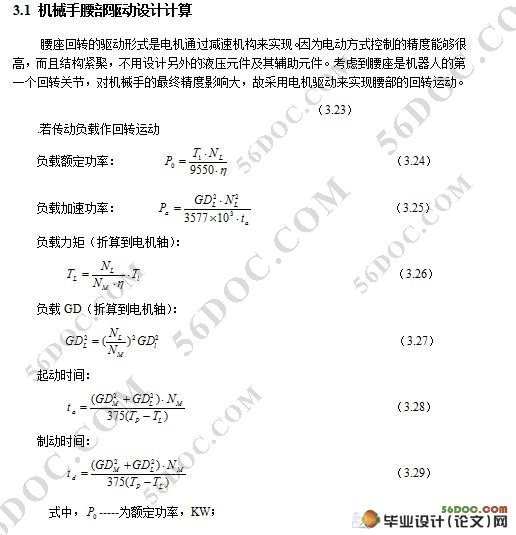

摘 要:随着机器人技术不断的发展,机器人在工业生产上应用越来越广泛,本设计就是运用机器人技术解决生产线生产效率低,劳动强度大,人生安全等问题,使机器人融入生产线。本设计通过对生产线的基本概况和数控机床装卸工件装置的研究和分析,明确了送料机器人的功能需求和动作流程。针对送料机器人的工作对象确定了夹持部分采用的机构,以及通过对其工作范围的分析确定了机器人的自由度,驱动方式,提出了送料机械手的整体设计方案。本文首先就如何设计及设计的必要性进行了论述,其中对机械本体的各部分工作原理和结构的设计进行了详细的论述。并且对主要的液压元件进行了设计和校核,以及对腰部回转齿轮进行了详细的设计。最后还有PRO-E三维设计软件对该送料机器人进行了造型。该送料机器人的速度、步进电机运行所需的脉冲数都可以根据具体的工况进行设置,能够满足在一定范围内数控机床上下料的多种作业要求,符合目前国内具体的生产加工水平,能满足一般企业生产要求。

关键词:机械手; 送料; 生产线; 机械设计

Design Of Feeding Robot Manipulator

Abstract:With the endless development of robot technology, the application of robot in industry is becoming more and more broad. The use of this design is use the robot technology to solve production line efficiency of the labor intensity, and life safety issues, make the robot into the production line completely. This is the research point of this topic.According to the research and analysis of CNC’s model basic situation, defining the function need and action flow. We have defined the gripping part of the feeding robot for material shape. As well as through an analysis of its work scope to determine the degree of robot’s freedom, the driving mode, putting forward the total design project of feeding robot. At first, this paper discusses how to design and the necessity of this design. All the mechanical parts of the body's working principle and structure design are discussed in detail, and there is some design and verification about the main components main components of the hydraulic. At the same time, i also have done a lot of calculation about slewing gear, just for the design as detail as i can. at last, I use PRO-E to complete the design of components of feeding robot, and it's basic modeling.The feed speed of the robot, stepper motor pulses needed for operation can be set based on specific conditions, in a certain range, and it also can meet a wide range of operational requirements expected of CNC machine tools up and down the work piece. It is in line with the current level of specific production and processing, can meet the general requirements of enterprises.

Key words: Manipulator; Feeding; Production Line; Mechanical design

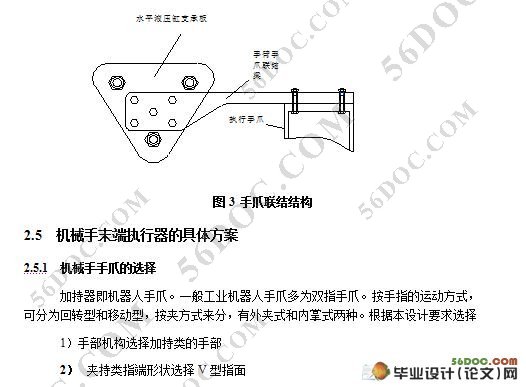

机器手的具体方案

工业机器人的结构形式主要有直角坐标结构,圆柱坐标结构,球坐标结构,关节型结构四种。

具体到本设计,因为要求搬运的加工工件的质量达30KG,且长度达500MM,同时考虑到数控机床布局的具体形式及对机械手的具体要求,考虑在满足系统工艺要求的前提下,尽量简化结构,以减小成本、提高可靠度。该机械手在工作中需要3种运动,其中手臂的伸缩和立柱升降为两个直线运动,另一个为手臂的回转运动,综合考虑,机械手自由度数目取为3,坐标形式选择圆柱坐标形式,即一个转动自由度两个移动自由度,其特点是:结构比较简单,手臂运动范围大,且有较高的定位准确度。