茶园旋耕机设计(含cad零件图和装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

茶园旋耕机设计(含cad零件图和装配图)(论文说明书7700字,cad图纸11张)

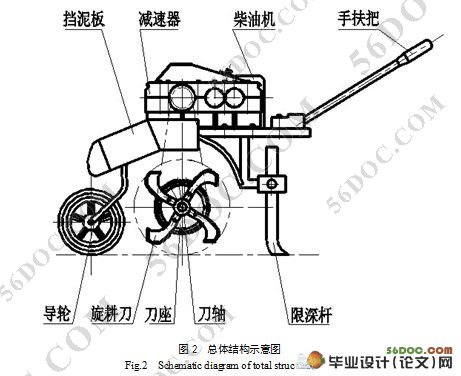

摘 要:我国的旋耕机目前不断配套新机具、增加新功能,在完善农用功能的基础上,逐步向城市园林、园艺领域扩展,如配套剪草、清雪、枝叶粉碎机具等;但暂未出现专用茶园旋耕机。本设计针对茶园作业环境和茶园作业要求,设计了一种小型茶园旋耕机用于松土、除草和起垄。该茶园旋耕机的机构包括机架、手扶手,机架上装有柴油机、减速器、链轮和耕作刀具。由柴油机将动力输送给减速器,减速器降低转速后输出给链轮,链轮经链条传递给刀轴,来实现旋耕刀的工作。旋耕刀旋转、以铣切原理加工土壤的耕整机械,具有切土效果好、碎土能力强、耕作地表平整等特点,一次作业可达到土碎地平。本茶园旋耕机可以爬坡,越埂、阶梯性强,适用我国广大丘陵和山区等地块小,高差大,无机耕道的茶园作业。

关键词:旋耕机;茶园;耕作刀具;减速器

Design of a Rotary Tiller Utilized in a Tea Garden

Abstract: Our Rotary tiller is supporting the current new machinery, new features. At the basic of improving the agricultural functions, gradually spread to the urban landscape, horticulture areas of expansion, such as supporting grass, cleaning snow, a mill and other branches; but there has been no special tea rotary tiller yet. The design aims for the tea and tea operational requirements of operating environment, designed for a small tea Rotary tillage, weeding and ridging. The rotary machine of tea include rack, hand rails, rack with diesel engines, gear, sprocket and farming tools. Power is transmission from the engine to the gear, after reducing speed, the output is transmitted to chain wheel ,and then passed to axis, to achieve the rotary blade work. Rotary blade revolves, by principle of milling processing of soil tillage machinery, cut soil with good effect, broken soil with strong capacity, and smooth the surface. Once work, it can achieve soil horizon. Rotary machine can climb the slope, the more ridge, the stronger step, can be applied for the vast number of hills and mountains which have little land, a large height difference, inorganic garden tractor road operations.

Key words: Rotary Tiller; tea garden; farming tool; reducer.

#p#副标题#e#

目 录

摘 要 1

关键词 1

1前言 3

1.1研究的目的和意义 4

1.2研究现状 4

1.3发展趋势 4

2总体设计 5

2.1总体结构方案确定 5

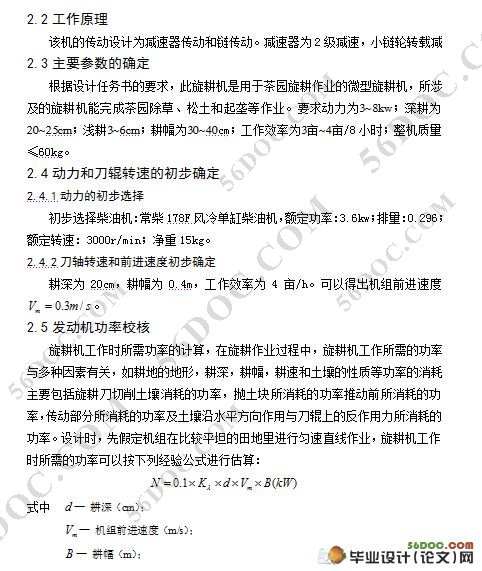

2.2工作原理 5

2.3主要参数的确定 6

2.4动力和刀辊转速的初步确定 6

2.4.1动力的初步选择 6

2.4.2刀轴转速和前进速度初步确定 6

2.5发动机功率校核 6

2.6旋耕机的设计 7

2.6.1旋耕刀的选择 7

3传动方案 9

3.1旋耕机传动类型的选择 9

3.2传动方案的确定 9

3.3计算各轴的设计参数 9

3.3.1传动效率的选定 9

3.3.2各轴输入功率 10

3.3.3各轴传动比的分配 10

3.3.4各轴输出转矩 10

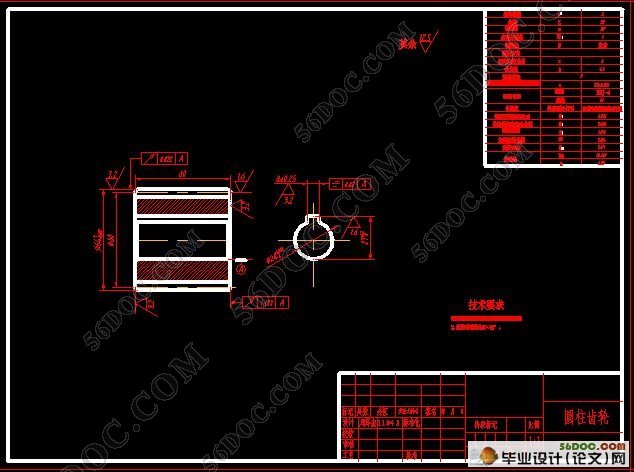

3.4齿轮的设计和校核 10

3.4.1第一级圆柱齿轮副的设计和校核计算 10

3.4.2他各直齿圆柱齿轮的几何计算 15

3.5链传动的设计计算 16

3.5.1选择链轮的齿数 16

3.5.2确定计算功率 16

3.5.3选择链条型号和节距 17

3.5.4计算链节数和中心距 17

3.5.5计算链速 ,确定润滑方式 17

3.6轴的设计计算 18

4润滑方法 21

5联轴器的选择 21

6限深装置的设计 22

7结论 22

参考文献 23

致 谢 24