基于PLC的模糊自适应PID控制器设计

无需注册登录,支付后按照提示操作即可获取该资料.

基于PLC的模糊自适应PID控制器设计(任务书,开题报告,外文翻译,论文说明书12000字)

摘 要

实际工业生产过程中可能有许多变量、不具备线性特性、时常改变且并不确定等特点,再考虑工程应用中控制的实时性、效率性和经济性等考量因素,使得对数学模型需求极高、时刻以最佳的性能指标为目标且计算方法通常非常繁复的现代控制理论在复杂的工业生产过程中难以发挥作用。使用模糊控制可以不用建立数学模型,很多繁复的情况的可以适应,被认为复杂控制的新方法。

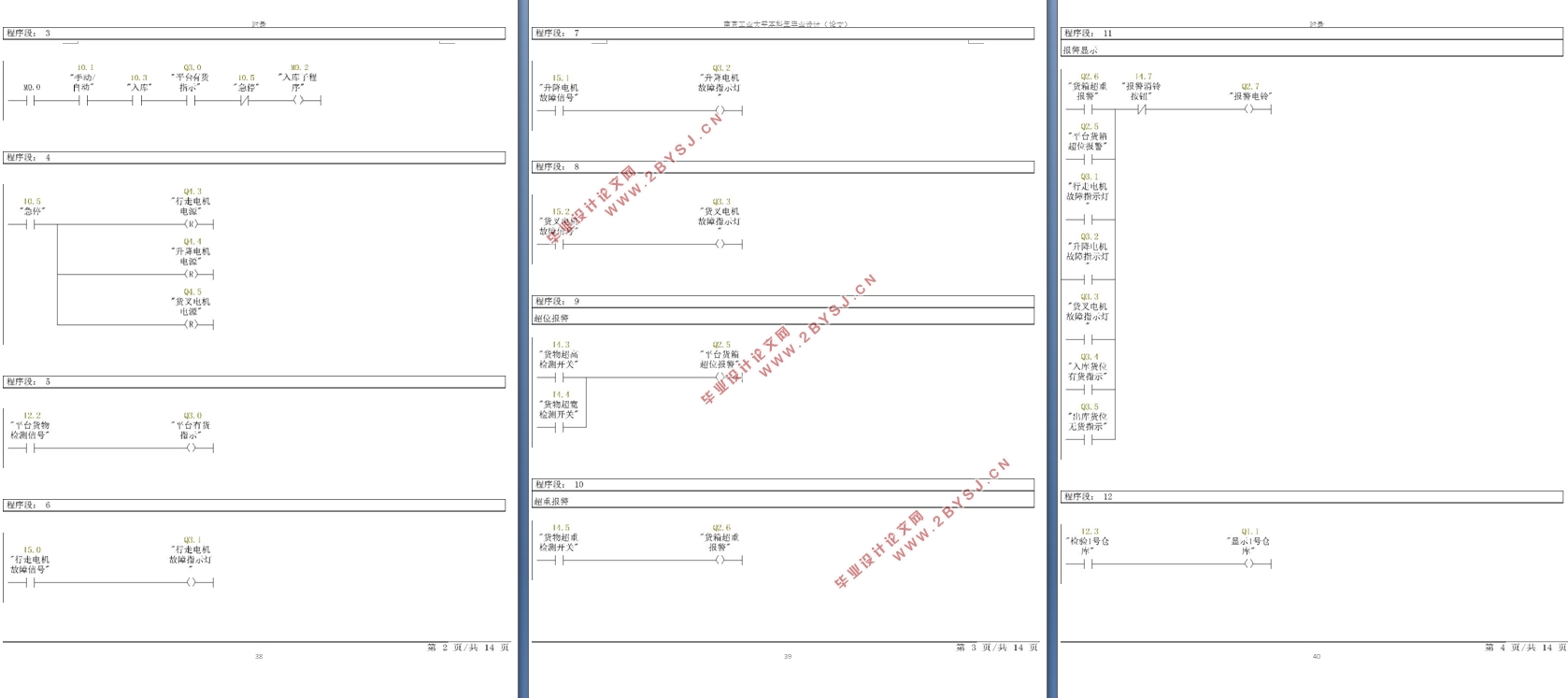

本设计首先凭借数学建模的方法获得双容水箱的模型,设计模糊PID控制器,计算得到模糊规则控制表。用仿真软件Matlab进行仿真。使用西门子组态软件STEP7 MicroWIN在S7-200PLC上实现模糊PID算法。使用监控组态软件WinCC编写界面,实时监控实验。实验结果表明,模糊PID控制效果优越,响应速度块且超调量小,抗干扰性远优于PID控制。

关键词:模糊PID算法 Matlab仿真 西门子S7-200PLC WinCC组态

Fuzzy Adaptive PID Controller Based on PLC

Abstract

The actual process of industrial production may have many variables which do not have a linear characteristic, do not change often,and is not determined by other characteristics.Consider ing the real-time control engineering applications, efficiency and economy and other considerations, such a high demand for mathematical models , always with the best performance for the target and the calculation method is usually very complicated modern control theory is difficult to play a role in complex industrial processes.

Fuzzy Control can be used without a mathematical model.It can also adapt tomany complex cases.As a result,it is considered to the new complex method of control .

The design is first obtained by the method of mathematical modeling with double - tank model.Then design the fuzzy PID controller and calculate the fuzzy control rules table. The process of simulation is realized by using simulation software Matlab.

Fuzzy PID algorithm is realized in Siemens configuration software STEP7 MicroWIN.

Using the configuration software WINCC to write interface and realize real-time monitoring experiments.

Experimental results show that the fuzzy PID control performance is superior to PID control with faster response and smaller overshoot.

Keywords: Fuzzy PID algorithm; Matlab simulation; S7-200 PLC; STEP7 MicroWIN; WINCC

目 录

摘 要 I

Abstract II

第一章 绪论 1

1.1 过程控制领域发展的概况 1

1.2 模糊控制发展概况 2

1.3 本文所做的工作和论文的结构篇幅安排 3

第二章 对双容水箱进行建模 5

2.1 实物模型 5

2.2 数学模型 6

第三章 模糊PID控制器设计 8

3.1 PID控制 8

3.1.1 PID参数整定法 9

3.2 具有自适应功能的模糊PID控制器设计 10

3.2.1 关于控制系统构架的设计 10

3.2.3 模糊控制算法的确立 10

3.3 模糊PID控制系统仿真 22

第四章 模糊控制在双容水箱上的实现 27

4.1 模糊PID算法在双容水箱上的实现 27

4.2 基于WINCC的监控界面设计 30

第五章 总结和展望 31

5.1 完成的工作 31

5.2展望 31

参考文献 32

致谢 34