基于罗克韦尔PLC的二次增压供水系统设计(附CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

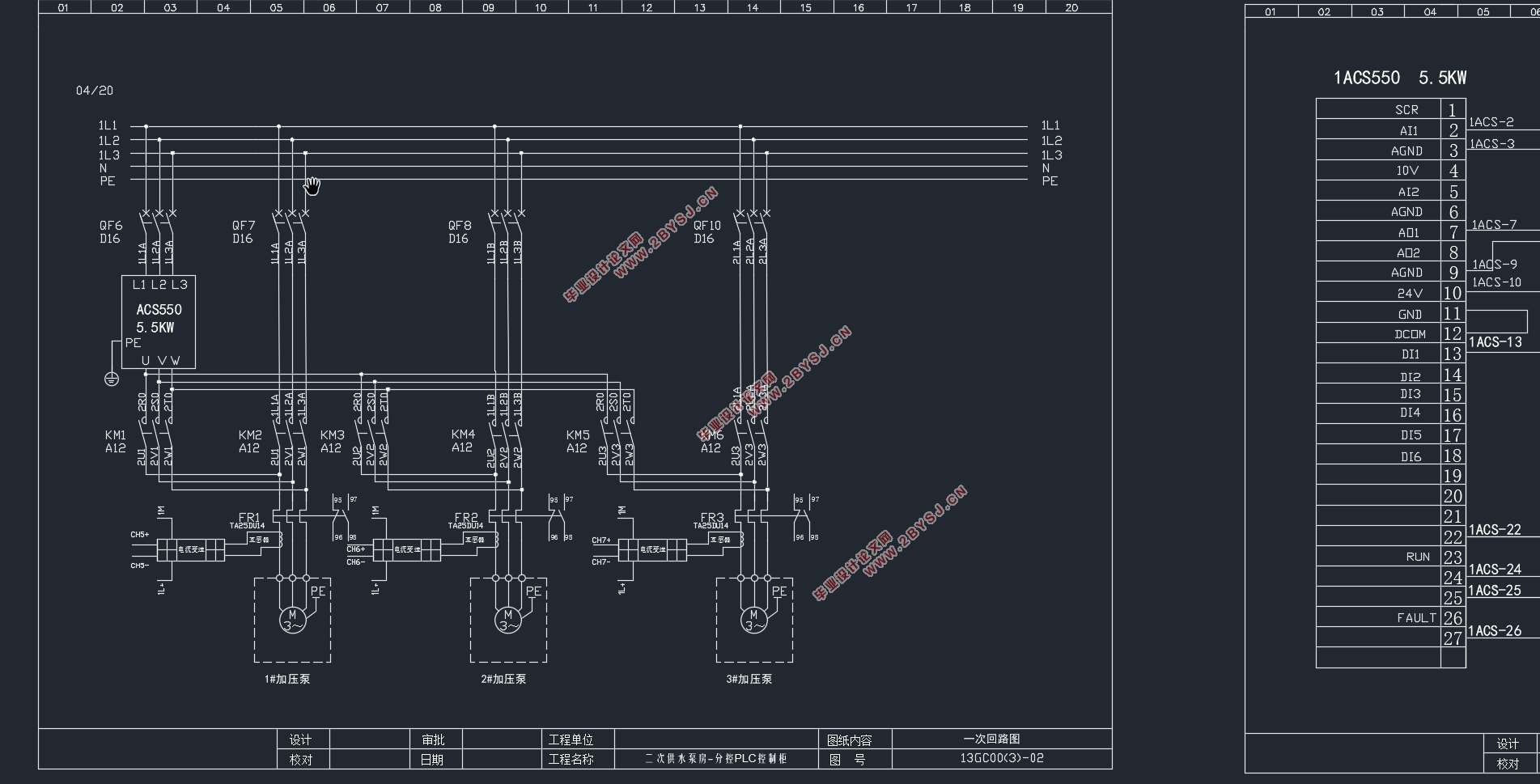

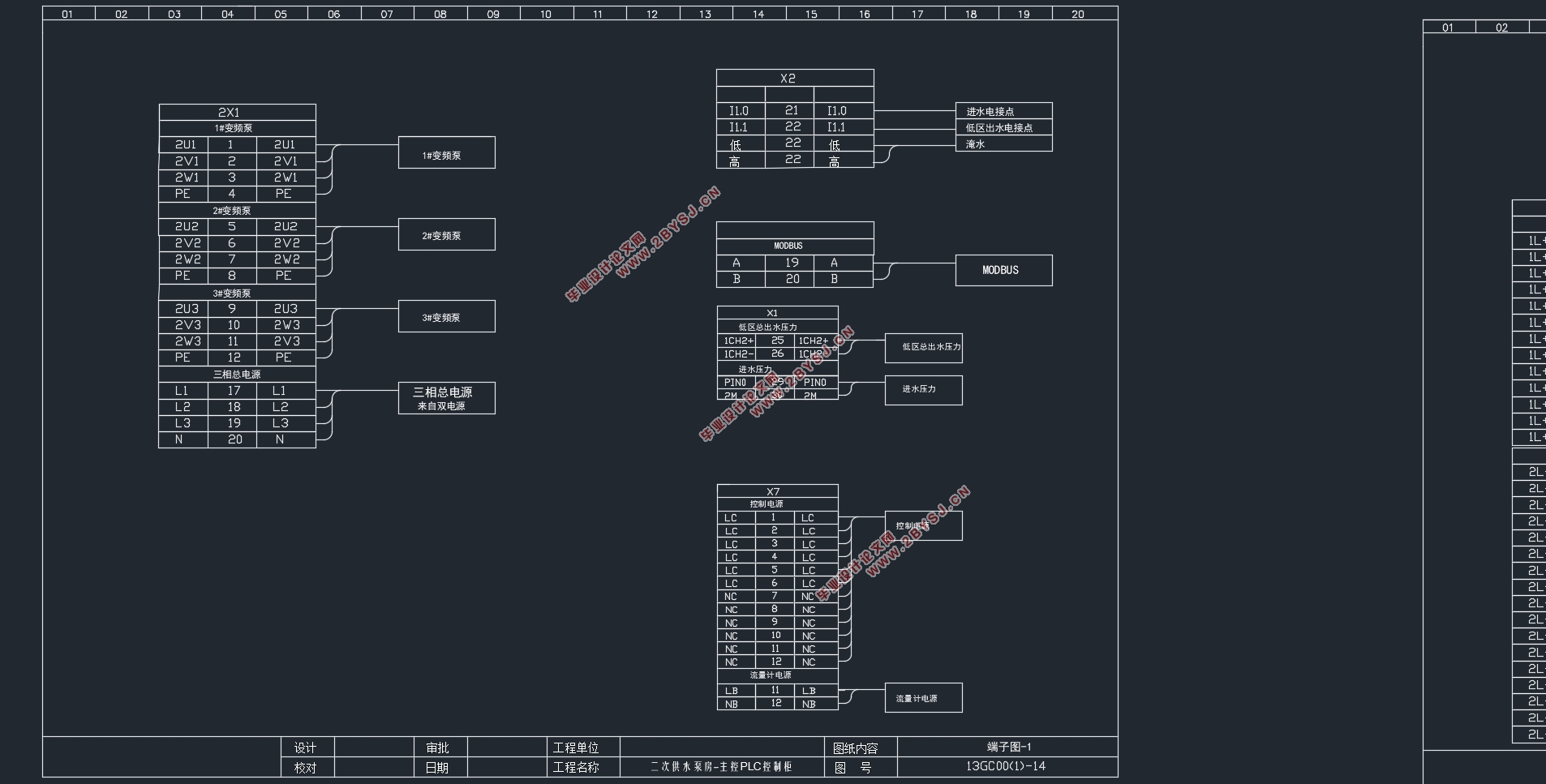

基于罗克韦尔PLC的二次增压供水系统设计(附CAD图)(任务书,开题报告,外文翻译,论文说明书11000字,CAD图19张合一)

摘 要

在现代工业和自动化工程中,PLC的可靠性、抗干扰因素能力是无法比拟的。随着计算机技术的发展,为工业自动化带来了深刻的变化,它的出现推进继电器计算机的发展。

设计的核心是三个供水泵组成的一个系统,该系统主要有和微机系统两个系统在Compact Logix 1766 PLC为控制中心,由控制泵站的压力目标值,PID算法,实现恒压供水的PC。intouch10.0 Wonder ware软件系统设计、数据库SQL Server 2005。该控制系统是稳定的,具有较高的可靠性。设计该系统是为了供水系统提高自动化程度和可靠性,增强供水稳定性。

因为水泵的供水流量是正比于水泵的转速的,成立方正比,本文使用了工频变频的转换配合控制来实现节能的恒压供水模式。通过变频器内部的PID模块,进行预先设置,设置成需要的参数,再通过远传压力表,反馈出水压的大小,构成一个回路,再根据用水量的变化,使用PID控制,在整个系统内部,使用工频变频配合,实现高效的恒压供水系统。

论文表明了采用多个泵并联供水的合理性,描述了在正常情况下,多个泵的工作方式和条件等,分析了电机由变频转工频运行方式的切换过程及存在的问题。给出了能够进行有效循环转换控制的设计方案和PLC控制程序设计方案。运用计算机和PLC之间的通信协议,完成了上、下位机之间的通信 ,通过该设计实现了对系统的远程的监控以及对于故障的报警功能。

关键词:罗克韦尔PLC PID算法 恒压控制

The design of the twice pressurized water supply system based on Rockwell PLC

Abstract

In the modern industry and automation engineering, the reliability of PLC and the ability of anti-interference factor are incomparable.. With the development of computer technology, it has brought revolutionary change to industrial automation, which is a leap of relay computer..

Core design is a system composed of three water pump, the system and the computer system in the CompactLogix 1766 PLC for control center, is controlled by the pumping station pressure target value, PID algorithm, PC of constant pressure water supply. Wonder ware intouch10.0 software system design, database Server SQL 2005. The control system is stable and has high reliability.. The system is designed to improve the degree and reliability of the water supply system, and enhance the water supply stability..

Due to the third power of the water pump flow and pump speed, is proportional to the relationship, the paper refers to the frequency control of motor speed to achieve constant pressure water supply relative to the traditional valve control way of constant pressure water supply energy-saving mechanism. Through the inverter embedded PID module parameters preset, using a remote pressure gauge pressure feedback, to form a closed loop system, according to the change of water, adopting the PID regulation, in the whole range of flow the pump frequency conversion of continuous regulation and power frequency pump grading regulation combined, the realization of constant pressure water supply and effective energy saving.

This suggests that the more the rationality of water pumps in parallel, describes in normal circumstances, multiple pump working methods and conditions, analysis of the motor by frequency conversion transfer switching process of power frequency operation mode and existing problems. The design scheme of the electrical design scheme and PLC control program for the realization of the effective state cycle conversion control is given.. The communication protocol between computer and

PLC is completed, and the communication between the upper and the lower computer is accomplished. The remote monitoring of the system and the alarm function of the fault are realized through the design.

Key words:Rockwell PLC; PID algorithm; Constant pressure control

摘 要 I

Abstract II

第一章 绪论 1

1.1 二次增压控水系统的现状 1

1.1.1 增压供水的形式 1

1.1.2 泵组现有的运行方式 1

1.1.3 蓄水池水质现状 1

1.1.4 供水系统结构分析 1

1.1.5 系统控制原理分析 2

1.2 可编程控制器的工作原理 3

第二章 硬件设计 4

1.硬件选型 4

2.系统设计 6

3.WINCC flexible搭建组态 19

第三章 软件设计 24

3.1软件设计分析 24

3.2 恒压变频供水控制流程 26

3.3水循环模块控制流程 27

3.4工频变频切换 28

3.5主程序自动部分流程 29

3.6系统程序设计 30

总结 33

参考文献 36

致 谢 40