基于PLC的阻燃剂分离膜过滤自控系统设计(附CAD图,winCC组态画面)

无需注册登录,支付后按照提示操作即可获取该资料.

基于PLC的阻燃剂分离膜过滤自控系统设计(附CAD图,winCC组态画面)(任务书,开题报告,论文说明书13000字,CAD电气柜设计图,winCC组态画面)

摘要

在现代化工业生产过程中会产生大量的工业废水,污染水资源,破坏环境,降低生产效率,根据统计的数据来看,我国因环境问题而产生的损失几乎占了整个国民生产总值的10%。若能高效处理回收工业废水,不仅能保护生态系统,亦能降低生产成本,提高产值。

阻燃剂,是赋予易燃聚合物难燃性的功能性助剂,能够阻燃高分子材料。三聚氰胺氰尿酸盐是由三聚氰胺和氰尿酸合成的盐,属于氮系列阻燃剂。生产中部分三聚氰胺氰尿酸盐会溶于水中产生乳白色浊液,不符合我国环保标准,无法直接排放,因此阻燃剂废水的过滤分离十分重要。根据相关文献,三聚氰胺氰尿酸盐具有一种特殊的性质,在30度时几乎不溶于水的,因此可利用这个特性设计阻燃剂分离膜自控系统。

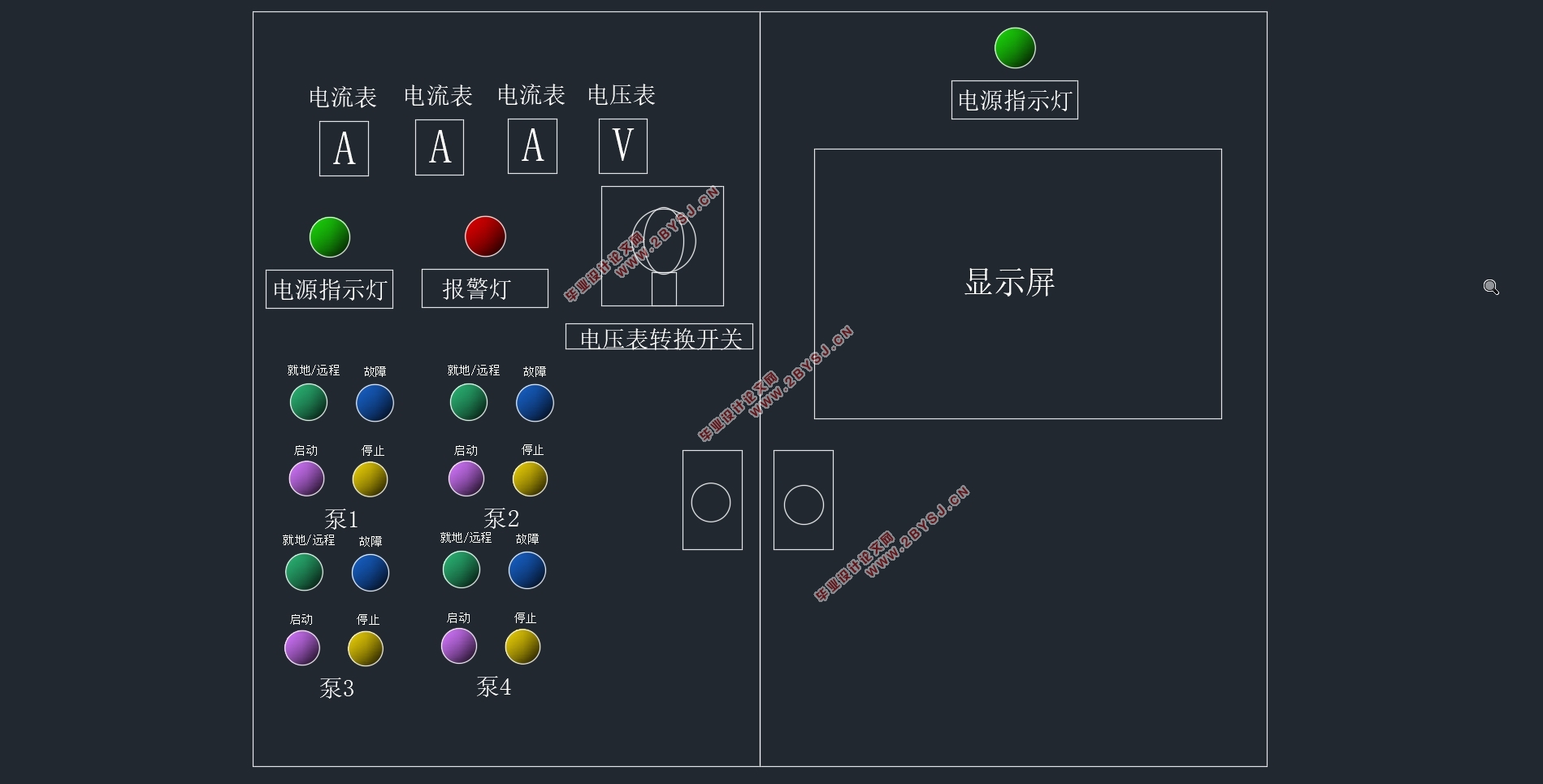

本设计具体工作内容包括根据工艺流程图统计控制点数,进行仪表选型;利用CAD软件绘制出电气柜设计图,根据选用设备具体情况安排接线和柜内分布;以西门子S7-1200PLC作为控制器,采用step7软件编写满足工业流程和生产需求的逻辑程序;用winCC上位机组态软件软件绘制人机友好的监控界面;模拟运行逻辑程序和监控界面,调整控制器参数。模拟实验表明本自控系统运行稳定,精确地控制了废水中阻燃剂的含量,使废水的排放符合国家标准。

关键词:废水处理自动控制远程监控

Abstract

In the process of modern industrial production, a large amount of industrial waste water will be produced, which will pollute water resources, damage the environment and reduce the production efficiency. According to the statistical data, the losses caused by environmental problems in China account for almost 10% of the whole GDP. If the industrial wastewater can be treated and recycled efficiently, not only the ecological system can be protected, but also the production cost can be reduced and the output value can be increased.

Flame retardant, is to give flammable polymer flammability of functional additives, can flame retardant polymer materials. Melamine cyanurate is a salt synthesized from melamine and cyanurate. It belongs to a series of flame retardants of nitrogen. Part of the production of melamine cyanuric acid salt will be dissolved in water to produce milky turbid liquid, does not meet China's environmental standards, can not be directly discharged, so the flame retardant wastewater filtration and separation is very important. According to relevant literatures, melamine-cyanurate has a special property, which is almost insoluble in water at 30. Therefore, this property can be used to design the automatic control system of flame retardant separation film.

The design of the specific work includes the flow chart according to the statistical control points, instrument selection; Use CAD software to draw the design drawing of electrical cabinet, and arrange wiring and distribution in the cabinet according to the specific situation of selected equipment; Siemens s7-1200 PLC is used as the controller and step7 software is used to write the logic program to meet the industrial process and production requirements. Draw the man-machine friendly monitoring interface with winCC upper machine state software; Simulate running logic program and monitoring interface, adjust controller parameters. The simulation results show that the automatic control system is stable, the content of flame retardant in wastewater is controlled accurately, and the discharge of wastewater meets the national standard.

Key words: waste water treatment;Auto-Control;Remote monitoring

目录

第一章绪论 1

1.1 课题研究背景与意义 1

1.2 国内研究现状 2

1.3 国外研究现状 3

第二章阻燃剂分离膜过滤过程分析 4

2.1 阻燃剂实验与特性 4

2.1.1 原理 4

2.1.2 实验内容及结果 4

2.2 分离膜过滤过程 4

2.3 过滤效果分析 5

第三章阻燃剂分离膜过滤系统设计与实现 6

3.1 仪表仪器选型 6

3.2 工艺流程与电气柜设计 8

3.2.1 工艺流程图 8

3.2.2 电气柜的设计 9

3.3 PLC程序设计 11

3.3.1 可编程控制器PLC的基本概念 11

3.3.2 PLC的特点以及应用领域 12

3.3.3 PLC的分类 12

3.3.4 PLC的硬件结构 12

3.3.5 PLC的选型 13

3.3.6 I/O地址的配置 14

3.3.7 PLC程序设计 16

3.4 监控组态设计与实现 25

3.4.1 winCC组态软件简介 25

3.4.2 winCC与PLC之间的通讯以及变量连接 25

3.4.3 组态画面设计与变量连接 28

第四章调试与运行结果 31

第五章总结与展望 33

5.1 论文总结 33

5.2 前景展望 33

参考文献 35

致谢 37