基于PLC的滚切控制系统设计

无需注册登录,支付后按照提示操作即可获取该资料.

基于PLC的滚切控制系统设计(论文11000字)

摘要:本文主要写了我在信捷实习期间在他们公司使用信捷plc,触摸屏,伺服驱动器,滚切机器,传感器等来实现自己滚切控制系统所要实现的功能。并分别阐述了PLC,伺服,触摸屏,滚切机的选型;系统各项功能模块;编程软件的挑选;有些指令的基本功能和指令相互嵌套使用的效果等。编写的软件是信捷公司自己研发的语句XDPPro,使用的编程方式是梯形图编程。主要要实现的功能:单多段的切换;单段定量有无效的切换;暂停和急停的区别使用;切刀复位;手动模式和定标模式等。并对各功能加以程序,图文讲解。在滚切控制系统设计的时候需要考虑的有逻辑性的贯通,各功能之间衔接自然,程序的简洁化和创新化和基本指令的择优化挑选。经过这一系列的步骤,最终才能得到一个稳定的滚切控制系统。

关键词:PLC;触摸屏;伺服;

Design of Rolling Control System Based on PLC

Abstract:This article mainly describes how I used the Xinjie plc, touch screen, servo driver, hobbing machine, and sensors in my company during my internship with Xin Jie to achieve the functions of my own roll control system. And elaborated the selection of PLC, servo, touch screen, hobbing machine; various functional modules of the system; the selection of programming software; the basic function of some instructions and the effect of nested use of instructions. The software written is XDPPro, a statement developed by Xinjie Company. The programming method used is ladder diagram programming. Mainly to achieve the function: a single multi-segment switch; single-segment quantitative invalid switching; the difference between the use of pause and emergency stop; cutter reset; manual mode and calibration mode. And to the various functions to the program, graphic explanation. In the design of the roll-cut control system, it is necessary to consider the logical link, the convergence of functions, the simplification and innovation of the program, and the selection of the basic instructions. After a series of steps, a stable hobbing control system can be finally obtained.

Key words: PLC; touch screen; servo;

目 录

1 绪论 1

1.1 课题背景及意义 1

1.2 国内外发展现状 1

1.3 论文研究的内容 2

2 系统介绍 2

3 机械结构选型 3

3.1 PLC选型 3

3.1.1 PLC种类 3

3.1.2 Modbus通讯参数设置 3

3.2 伺服选型 4

3.2.1 伺服规格 4

3.2.2 DS3E、DS3L、DS3-PTA、DS2 全系列伺服驱动器比较表 4

3.2.3 DS3E伺服特点 6

3.3滚切机选型 7

3.4 触摸屏选型 7

4 系统功能模块 9

4.1系统整体流程图 9

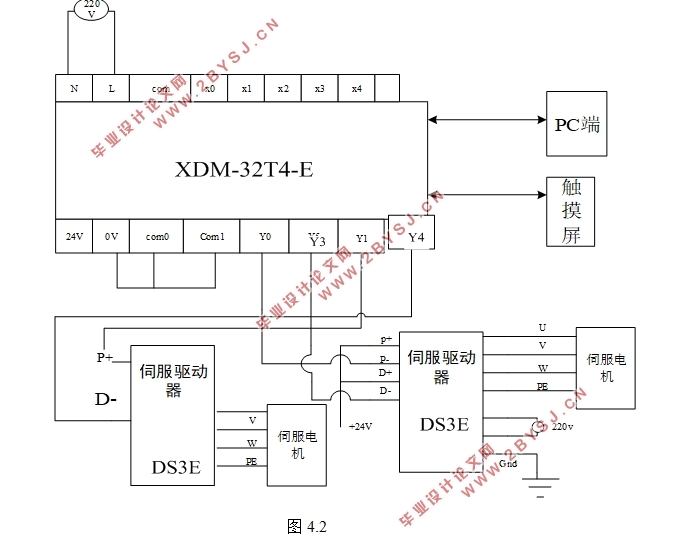

4.2 系统整体接线图 10

4.3 系统各段功能 10

5 系统调试及结果分析 17

5.1 PLC编程软件介绍 17

5.2程序编写过程及系统调试 17

6 总结和展望 25

参考文献 26

致谢 27