基于STM32的电压采集系统的设计

无需注册登录,支付后按照提示操作即可获取该资料.

基于STM32的电压采集系统的设计(任务书,开题报告,外文翻译,论文13000字,答辩记录)

摘 要

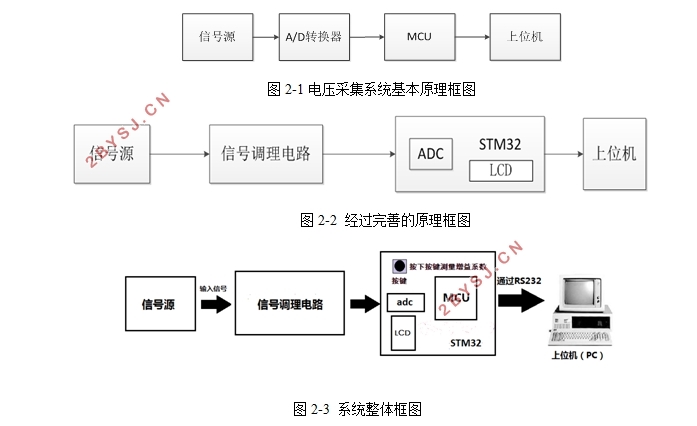

本课题基于STM32开发板,设计了一款能够采集-3V~3V直流电压的电压采集系统。由于STM32开发板的A/D模块只能采集正电压,所以本课题需要设计一个电路可以使输入信号转变为STM32能够采集的电压,该电路即为信号调理电路。文中第一章首先是对电压采集系统的历史背景和设计意义和现状进行了分析,第二章则是对基于STM32的电压采集系统进行需求分析以及问题的解决方案。第三章则对硬件部分的具体实现过程进行了说明,列出不同的方案并加以分析,进行对比选出最合适的电路。在理解了采集系统的功能要求和芯片使用方法后,设计了软件流程,分析了主要的程序段。接下来是软件和硬件联合调试,描述了实际调试中遇到的问题,并分析原因。本文的结尾对该系统进行了误差的分析和改进。

关键词:电压采集系统 信号调理电路 STM32

The voltage acquisition system based on STM32

Abstract

On the basis of STM32 development board, this research designs a voltage acquisition system which can acquires -3V~3V direct voltage. Since the A/D module of STM32 development board can only acquire positive voltage, this research needs to design a circuit which can convert the input signal into the voltage that can be acquired by STM32. This circuit is signal conditioning circuit. The first chapter analyzes the historical background, significances and current situation of voltage acquisition system; the second chapter is the requirements analysis and the solutions to the problems based on voltage acquisition system; the third chapter explains the concrete realization process of its hardware, lists and analyzes various schemes, and selects the most proper circuit after comparison. After understanding the function requirements of acquisition system and the usage of chip, the writer designs the software process and analyzes the main program segment. And next is to debug both the software and hardware, describes the problems in the practical debugging and analyzes their reasons. The last part of the paper analyzes the errors and improves this system.

Key Words : Voltage acquisition system; Signal conditioning circuit; STM32

目 录

摘 要 I

ABSTRACT II

第一章 绪 论 1

1.1课题的历史背景及发展 1

1.2课题的设计意义 2

1.3相关技术在国内外的发展情况 3

1.4 本文的安排 3

第二章 需求分析 5

2.1 需求分析 5

2.2 解决方案 6

第三章 硬件设计 9

3.1 设计过程 9

3.2 方案比较 13

3.3 STM32开发板的硬件外设 14

3.3.1 USART 14

3.3.2 ADC 15

第四章 软件设计 16

4.2 程序流程图 16

4.3 STM32固件函数库 17

4.3.1 STM32固件库的配置以及STM32的初始化 17

4.3.2 功能说明 19

第五章 电路制作与调试 21

5.1硬件的购买与调试 21

5.1.1硬件的购买 21

5.1.2硬件的焊接 21

5.1.3硬件的测试 22

5.1.4硬件的调试 22

5.2软件调试 24

第六章 误差分析以及改进方法 25

6.1误差的分析 25

6.2误差的测量 26

6.3改进方法 28

结 语 30

参考文献 31

致 谢 32