基于STM32的锥度仪设计

无需注册登录,支付后按照提示操作即可获取该资料.

基于STM32的锥度仪设计(任务书,开题报告,论文10000字)

摘要

连铸技术的应用日益广泛,而结晶器对于连铸机的影响显得格外重要。结晶器的开口度大小以及锥度的改变都会对铸坯的生产质量产生影响,如果开口度和锥度严重偏离正常值,就会造成严重的生产事故。因此,对结晶器进行快速精确的检测显得尤为重要。传统的结晶器检测设备存在精度较低、检测速度慢、操作不够简便等问题,不能够适应连铸生产的需求。相比之下,进口设备的精度较高但是价格高昂,维修成本高,这些都给国内企业带来了严重的困扰。为了解决上述问题,设计一款成本较低,精度较高,检测速度较快的结晶器测量仪就显得尤为急切。

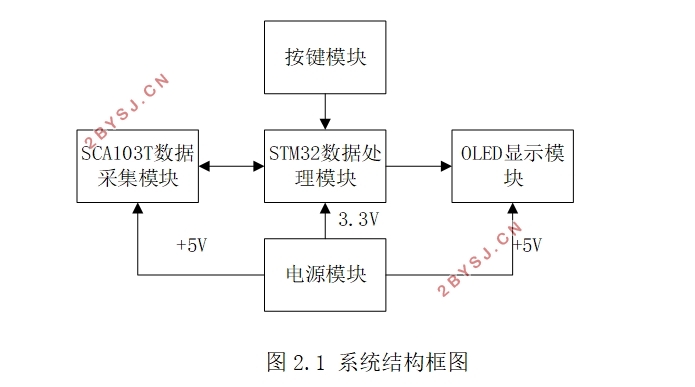

本文介绍了利用芬兰VTI高精度传感器SCA103T设计的锥度仪系统,介绍了SCA103T的工作原理及特性,同时介绍了使用STM32通过SPI方式读取SCA103T测量数据的方法,并且给出了STM32与SCA103T进行SPI通讯的电路原理图,同时给出了在Keil环境下STM32通过SPI库函数直接读取SCA103T加速度的程序,通过仿真测试表明,本设计能够较好地实现锥度仪的测量和水平校准功能。

关键词:锥度仪;STM32;SCA103T;SPI

Abstract

The application of continuous casting technology has developed quickly, and the crystallizer has been more important to the continuous casting machine.The changes of opening degree and taper both affect the production quality of the casting blank. If the opening degree and taper deviate from the normal value, it will cause serious production accidents.Therefore, it is very important to check the crystallizer quickly and accurately.The traditional mold detection equipment has some problems such as low precision, slow detection and complex operation, which can’t meet the requirements of the continuous casting production.By contrast, imported equipment has high precision but at the same time ,they has high price and high maintenance cost, which bring serious troubles to domestic enterprises.In order to solve the problems, it is particularly urgent to design a mold measuring instrument with lower cost, higher precision and faster detection.

This paper introduces the taper instrument system design by the use of Finland VTI high-precision sensor SCA103T and the working principle and characteristics of SCA103T.This paper also introduces the method that the STM32 read the measureddata of SCA103T by the SPIcommunication mode.Besides this paper also gives thecircuit principle diagramthat the STM32 communicates with SCA103T by SPI.Beyond that,this paper also gives the code that the STM32 receives the datafrom SCA103T by SPI using the library functions in the Keil environment.Inthe end, the simulation test shows that this design can achieve the measurement and level calibration function of the taper instrument.

Key Words:Taper instrument;STM32;SCA103T;SPI

目录

第1章 绪论 1

1.1课题意义及背景 1

1.2国内外测量技术研究现状 3

1.3不同角度传感器的性能特点及应用 3

第2章 系统设计 4

2.1 锥度仪测量原理及功能 4

2.2芯片选型介绍 4

2.1 STM32单片机介绍 4

2.2 SCA103T及其工作原理 5

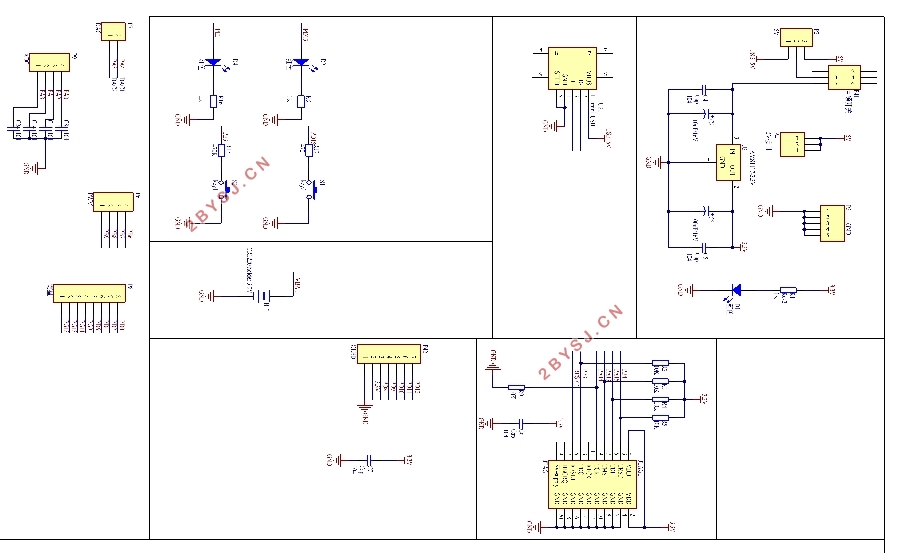

第3章 硬件电路的设计 6

3.1 SCA103T电路设计 6

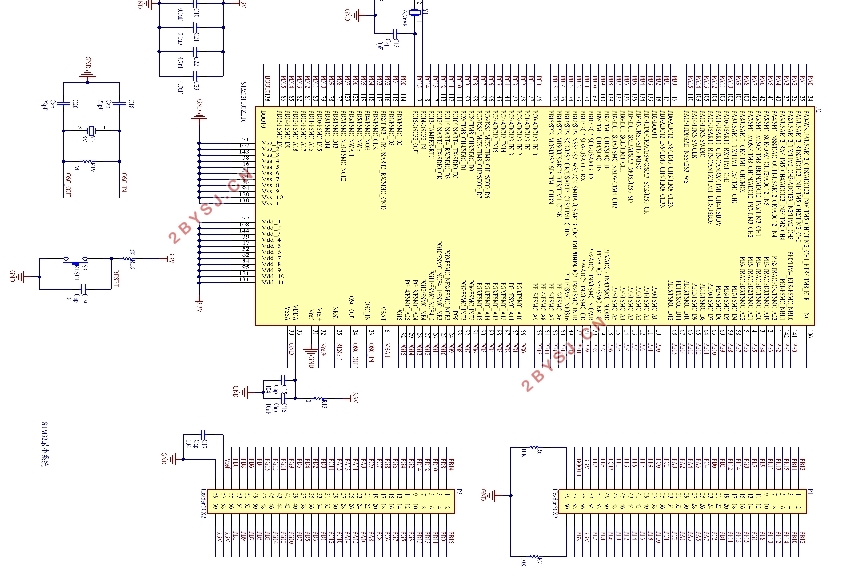

3.2 STM32电路模块 6

3.3 电源模块 7

3.4 显示模块 8

3.5 按键模块 9

3.6 下载电路接口 9

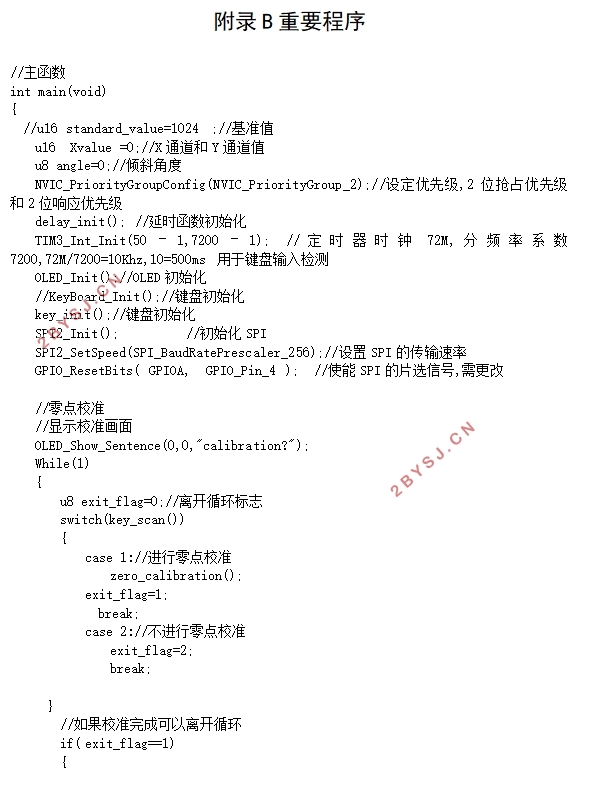

第4章 软件设计 11

4.1软件整体流程 11

4.2 SCA103模块 12

4.2.1 SCA103T的SPI通信方式 12

4.2.2 SCA103T子程序 13

4.2.3 SCA103T的数字输出转换为角度值 14

4.3 按键扫描函数 15

第5章 结论 16

参考文献 17

附录A STM32最小系统电路图 19

附录B 重要程序 20

致谢 23