基于单片机的PWM调压系统设计

无需注册登录,支付后按照提示操作即可获取该资料.

基于单片机的PWM调压系统设计(任务书,开题报告,外文翻译,论文14000字)

摘 要

随着社会的日益发展,对于各行各业,日常生活乃至专业研究,电压的可靠性使用已经越来越成为我们重点关注的问题。电压是权衡电能质量的根本指标之一,对于电压调整,几乎覆盖了这些科技电子产品的方方面面,很多核心部件对于电压是非常敏感的,因此这就对我们进行电压的调整适配提出了更高的更迫切的要求。

基于单片机的PWM调压,对于既定输入电压,无法满足我们所需要的标准电压时,那么就可以使用该调压方案,去通过一系列的电压变换,从而得到我们所需要的符合要求的目标电压。基于单片机的PWM调压技术是应用于汽车电子、消费电子、空调冰箱等智能家电变频等各种智能化科技化场景中的一项技术。它可以在使用场景中,使得场景更加的自动化和智能化,能够大大的提高人机交互性。

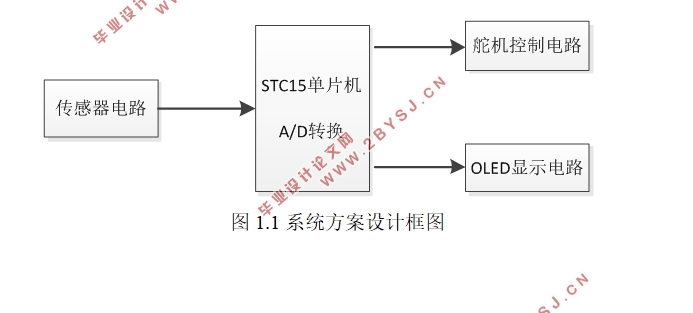

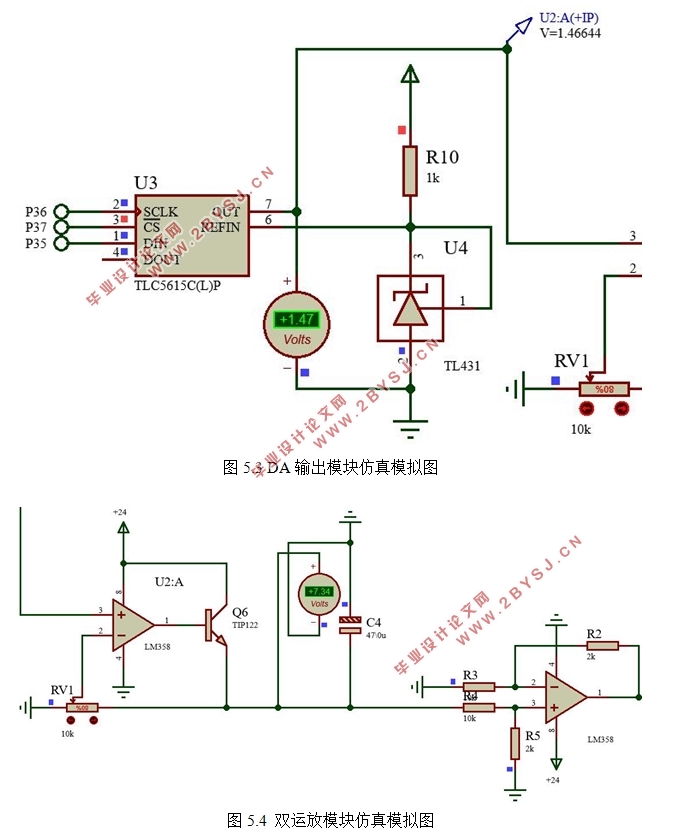

本文主要是对调压进行一个具体化研究探索,是基于单片机的PWM调压,首先我们给定直流24V电压,然后通过单片机控制数控电源电路,数控电源电路包括D/A输出电路、串联稳压电路以及负载,然后会得到直流0~15V的初始电压,之后会将这个初始输出电压作为电压反馈电路的输入,然后再接入A/D转换电路,最后将符合我们要求的结果显示在单片机液晶显示屏上。

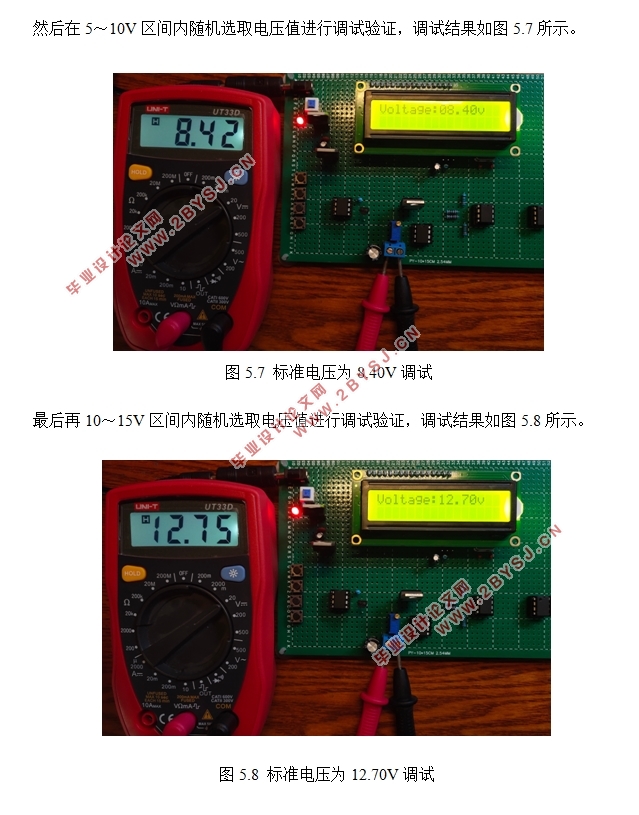

经过实验验证,本系统可以在直流24V既定输入电压的基础上对电压进行调节变换,其变换后的目标电压在直流0~15V范围内,并且本系统中所进行的变换是直流-直流的电压变换,而非直流-交流-直流变换。其不足之处在于,对于我们认为设定的目标电压而言,其液晶显示屏输出的电压数值存在些许误差,因为本系统采用51单片机作为硬件主体,从而进行电路延伸扩展,存在的误差可在之后的具体实现方案中进一步优化减少。此外,本文提供的方法在保证基本输出精度的的前提下,尽量减少外界因素对输出精度的影响,直流24V我采用了直流稳压电源适配器,能在一定程度上去减少硬件运行发生意外的概率。通过实际操作验证,证明了本文的系统设计思路的正确性,达到了我们的期望值,具有较好的实用性。

关键词:单片机;PWM调压;电压变换;输出精度

Abstract

With the development of society, for all walks of life,daily life and even professional research, the reliability of voltage has become more and more our focus. Voltage is one of the fundamental indicators for weighing power quality. For voltage adjustment, it covers almost all aspects of these technology electronics. Many core components are very sensitive to voltage, so this puts higher voltage adjustment adjustment for us. More urgent requirements.

Based on the PWM voltage regulation of the single chip microcomputer, if the standard voltage is not enough for the given input voltage, then the voltage regulation scheme can be used to pass a series of voltage conversions to obtain the required target voltage. . The PWM voltage regulation technology based on single chip microcomputer is a technology applied in various intelligent scientific and technological scenes such as automobile electronics, consumer electronics, air conditioner refrigerators and other smart home appliances. It can make the scene more automated and intelligent in the usage scenario, which can greatly improve human-computer interaction.

This paper is mainly to carry out a specific research and exploration on voltage regulation. It is based on PWM voltage regulation of single chip microcomputer. First, we give DC 24V voltage, and then control the digital power supply circuit through single chip microcomputer. The digital power supply circuit includes D/A output circuit and series voltage regulator. The circuit and the load will then get the initial voltage of 0-15V DC. After that, the initial output voltage will be used as the input of the voltage feedback circuit, and then connected to the A/D conversion circuit. Finally, the result that meets our requirements will be displayed on the LCD. On the display.

After experimental verification, the system can adjust and change the voltage based on the established input voltage of 24V DC. The converted target voltage is in the range of 0-15V DC, and the conversion in this system is DC-DC voltage. Transform, not DC-AC-DC conversion. The shortcoming is that, for the target voltage we think is set, there is a slight error in the voltage value of the liquid crystal display output. Because the system uses 51 single-chip microcomputer as the hardware main body, the circuit extends and expands, and the error can be Further optimization is reduced in the specific implementations that follow. In addition, the method provided in this paper minimizes the influence of external factors on the output accuracy under the premise of ensuring the basic output accuracy. I used a DC stabilized power adapter for DC 24V, which can reduce the probability of accidents in hardware operation to a certain extent. Through the actual operation verification, the correctness of the system design idea of this paper is proved, and our expectation value is achieved, which has good practicability.

Key Words:Single chip microcomputer; PWM voltage regulation; voltage conversion; output accuracy

目 录

第1章 绪论 1

1.1 研究目的及意义 1

1.2 国内外研究现状 2

1.3 研究内容说明 2

第2章 调压系统总体设计 4

2.1 调压系统需求分析 4

2.2 调压系统方案设计 4

第3章 调压系统硬件电路设计 6

3.1单片机最小系统电路 6

3.2 LCD硬件电路 7

3.2.1 LCD1602原理 8

3.2.2 LCD1602显示电路 9

3.3 电源模块设计 9

3.4 D/A输出电路设计 10

3.5 串联稳压整体模块电路设计 12

3.5.1 运算放大模块 13

3.5.2 A/D转换模块 14

第4章 调压系统软件设计 16

4.1 按键检测软件设计 17

4.2 串联稳压软件设计 18

4.3 A/D转换软件程序设计 19

4.4 液晶显示软件程序设计 20

第5章 调压系统调试与结果分析 21

5.1 调压系统调试 21

5.2 结果分析 26

第6章 总结与展望 27

参考文献 29

致谢 31