力矩电机伺服控制系统设计(含CAD电气图)

无需注册登录,支付后按照提示操作即可获取该资料.

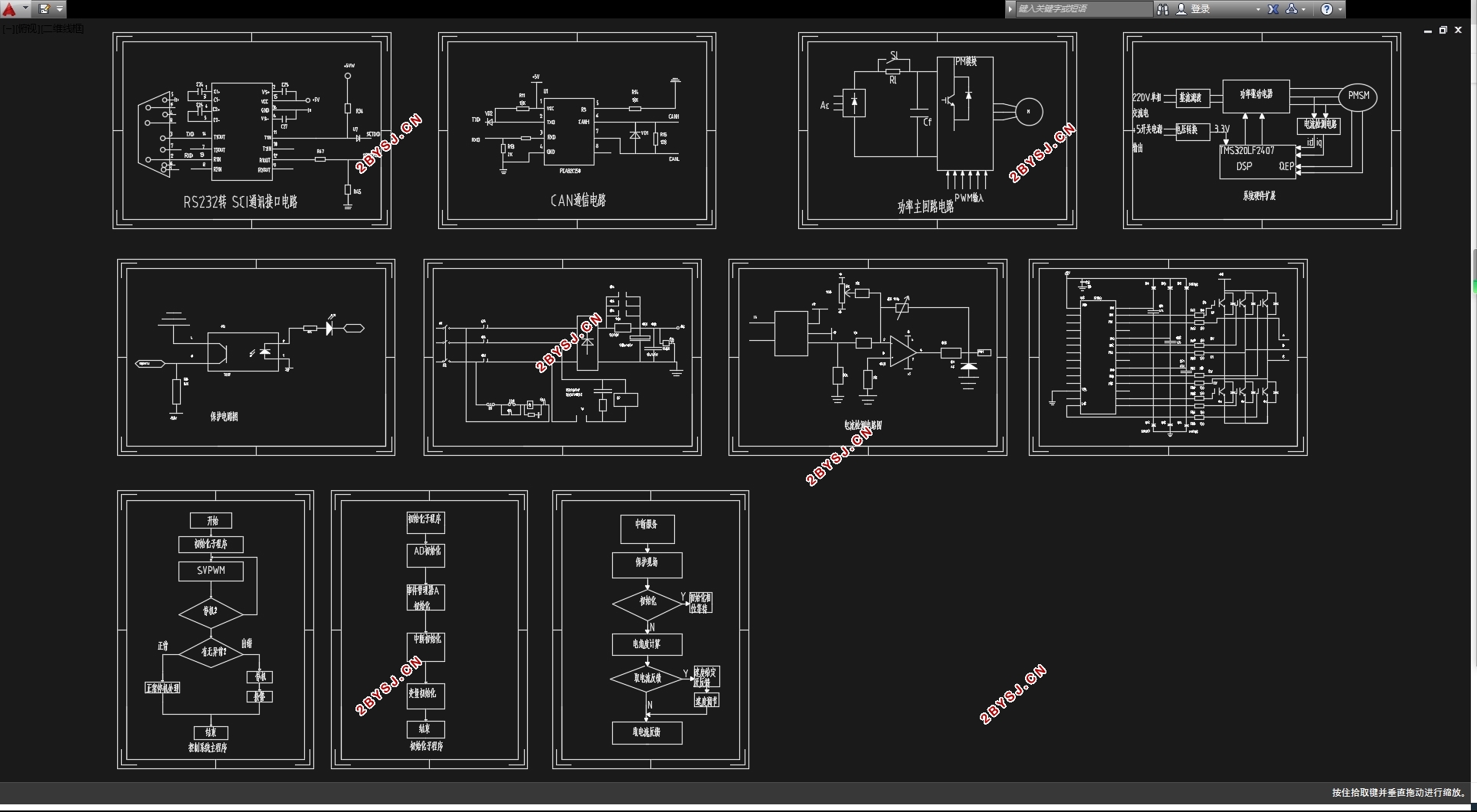

力矩电机伺服控制系统设计(含CAD电气图)(任务书,开题报告,论文说明书12600字,CAD图11张)

摘 要

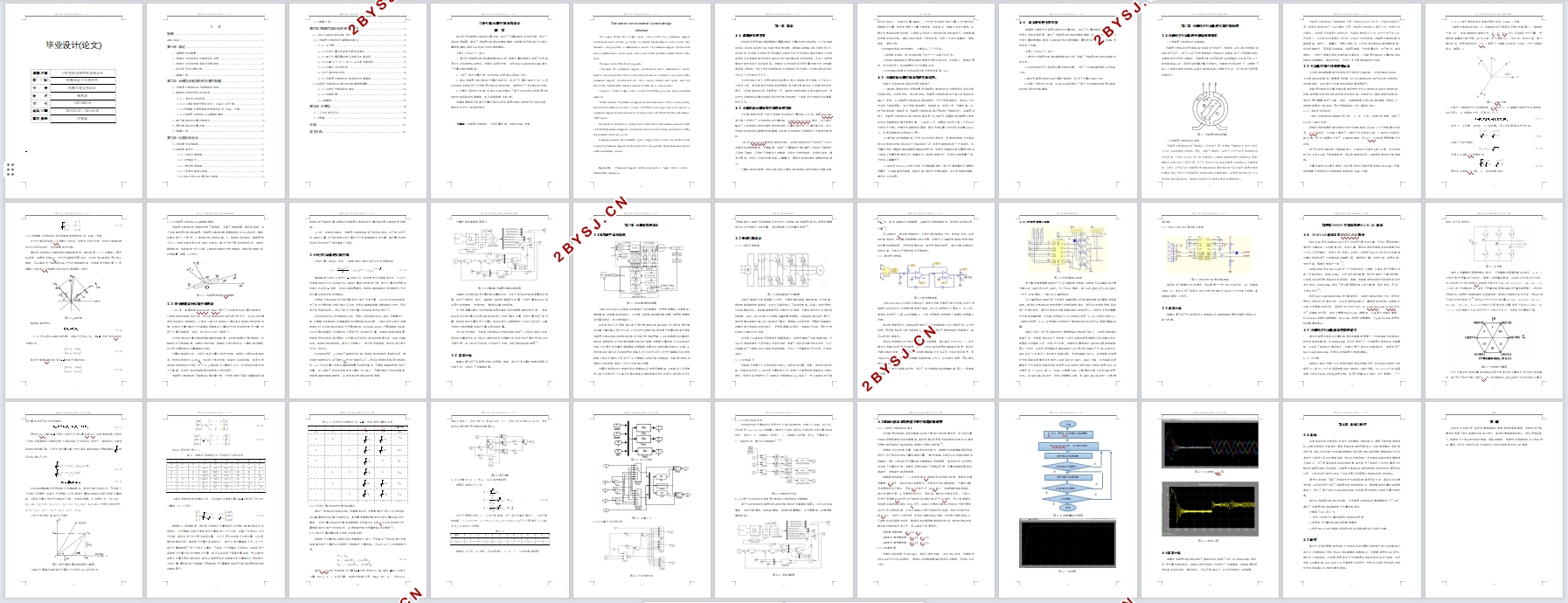

本文研究永磁同步电动机矢量控制,给出了矢量控制中的坐标变换,设计了系统的原理图,建立了永磁同步电动机的数学模型,驱动器中采用的电压空间矢量脉宽调制(简称SVPWM)方法的数学模型。

主要工作有以下几部分:

1.通过对永磁同步电动机数学模型的分析,根据矢量控制理论实现了对永磁同步交流伺服电机的电流、速度的双闭环控制,并用MATLAB/SIMULINK建立了矢量控制仿真模型。

2.分析了电压矢量控制(SVPWM)的原理以及构成方法。

3.建立永磁同步电动机的矢量控制系统,叙述了矢量控制的方法。应用SVPWM控制实现了对永磁同步电机的转矩控制,其表现出了直流电机的性能。

4.对整个系统进行仿真,在MATLAB中建立了基于SVPWM的永磁同步电动机控制系统的仿真模型,给出实验结果及其分析。

仿真结果表明空间电压矢量控制可以使永磁同步电机的转矩可控制并达到稳定并且产生三相稳定电流。

关键词:永磁同步电动机,空间矢量控制,SIMULINK仿真

The motor servo control system design

Abstract

This paper studies the voltage space vector control by permanent magnet synchronous motor system ,gives the coordinate transformation vector control, the schematic design system, a mathematical model of permanent magnet synchronous motor, a mathematical model space vector pulse width modulation method used in the drive.

The main work of the following parts:

1.Through the permanent magnet synchronous motor mathematical model analysis, according to the vector control theory to achieve a double-loop control of the permanent magnet synchronous AC servo motor current and speed, and use MATLAB / SIMULINK simulation model to establish a vector control.

2.Analysis of the voltage vector control (SVPWM) principles and constituted methods.

3.Establishment of permanent magnet synchronous motor vector control system, described the method of vector control. SVPWM control applications to achieve a permanent magnet synchronous motor torque control, which exhibits the performance of DC motor.

4.Simulation of the entire system, built on the MATLAB simulation model based on SVPWM permanent magnet synchronous motor control system, and analysis of the experimental results are given.

Simulation results show that the space voltage vector control allows the torque control of permanent magnet synchronous motor can generate three-phase and reaches a stable and steady current.

Keywords: Permanent magnet synchronous motor;Space vector control;SIMULINK simulation.

目 录

摘要...............................................................I

ABSTRACT....................................................... .II

第一章 绪论.......................................................1

1.1课题研究的背景...............................................1

1.2永磁交流伺服系统控制理论的发展...............................1

1.3永磁交流伺服控制系统的发展趋势...............................2

1.4论文研究的主要内容...........................................2

1.5本章小结.....................................................2

第二章 永磁同步电动机的矢量控制理.............................4

2.1永磁同步电动机的内部结构和种类...............................4

2.2电动机控制中用到的坐标系.....................................5

2.2.1 系统中的坐标系.........................................5

2.2.2三项到两相平面坐标系(Clarke)的变换....................6

2.2.3两相静止到两相旋转直角坐标系(Park)变换................7

2.2.4永磁同步电动机d-q轴数学模型............................8

2.3转子磁链定向矢量控制理论.....................................8

2.4同步电动机的矢量控制.........................................9

2.5本章小结.....................................................9

第三章 伺服系统设计.............................................11

3.1系统硬件总体结构............................................11

3.2典型电路设计................................................12

3.2.1功率变换电路..........................................12

3.2.2控制单元..............................................12

3.2.3电流检测电路..........................................13

3.2.4光电码盘接口电路......................................14

3.2.5RS232转SCI通讯接口电路...............................15

3.3本章小结....................................................15

第四章PMSM控制系统的MATLAB真................................16

4.1 MATLAB/SLMULINK简介.....................................16

4.2 永磁同步电动机仿真模型的建立................................16

4.2.1逆变器.................................................16

4.2.2空间矢量PWM发生模块的建立...........................20

4.2.3电压矢量所属的扇区判断及仿真实现.......................20

4.2.4计算X,Y,Z,T1和T2,以及其仿真实现.....................21

4.2.5计算开关作用时间.......................................22

4.2.6生成PWM波形..........................................23

4.2.7永磁同步电动机控制系统的仿真模型.......................23

4.3双闭环仿真系统的建立和控制器参数调整.........................24

4.3.1双闭环仿真系统的建立...................................24

4.3.2仿真结果...............................................25

4.4本章结...................................................26

第五章结束语....................................................28

5.1工作总结及评价..............................................28

5.2展望........................................................28

致谢..............................................................29

参考文献.........................................................30