SUS304薄板器件焊接器件夹具设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

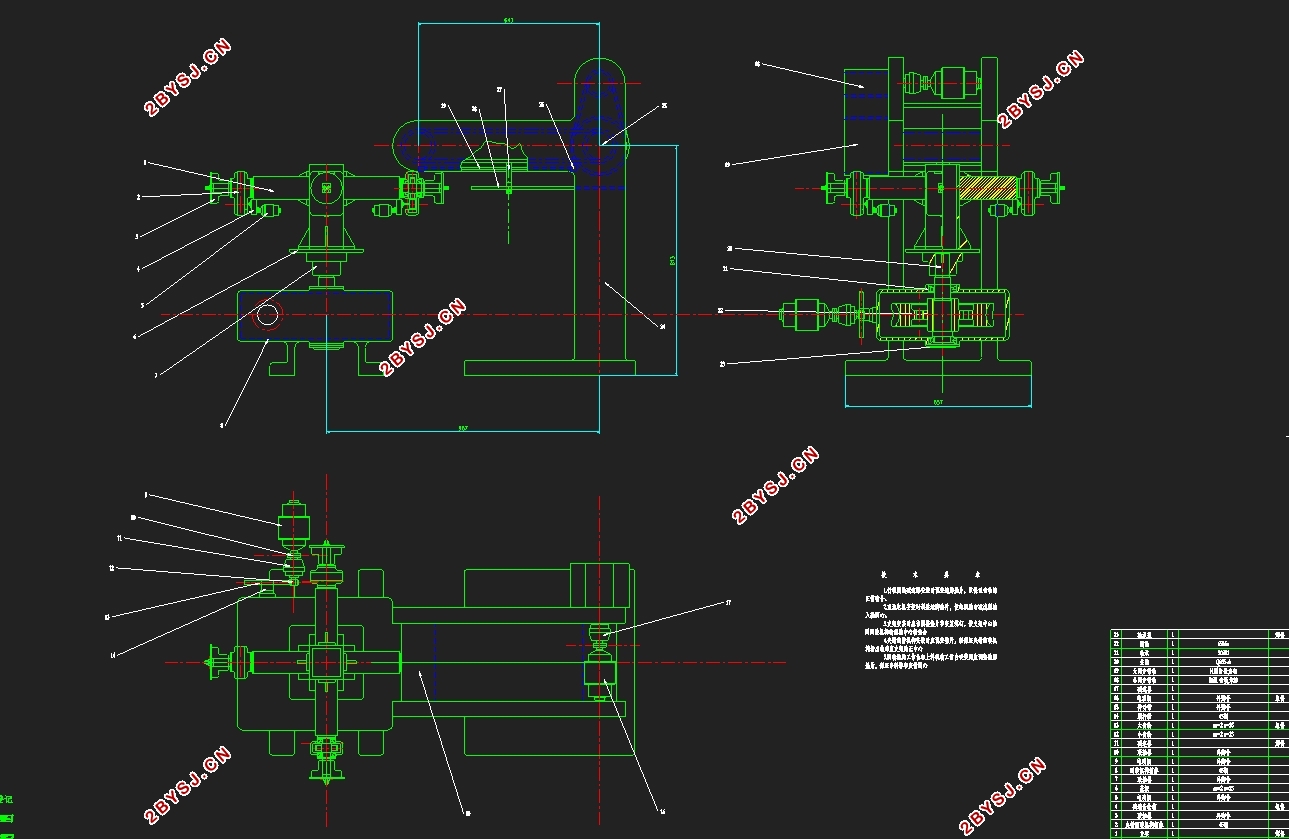

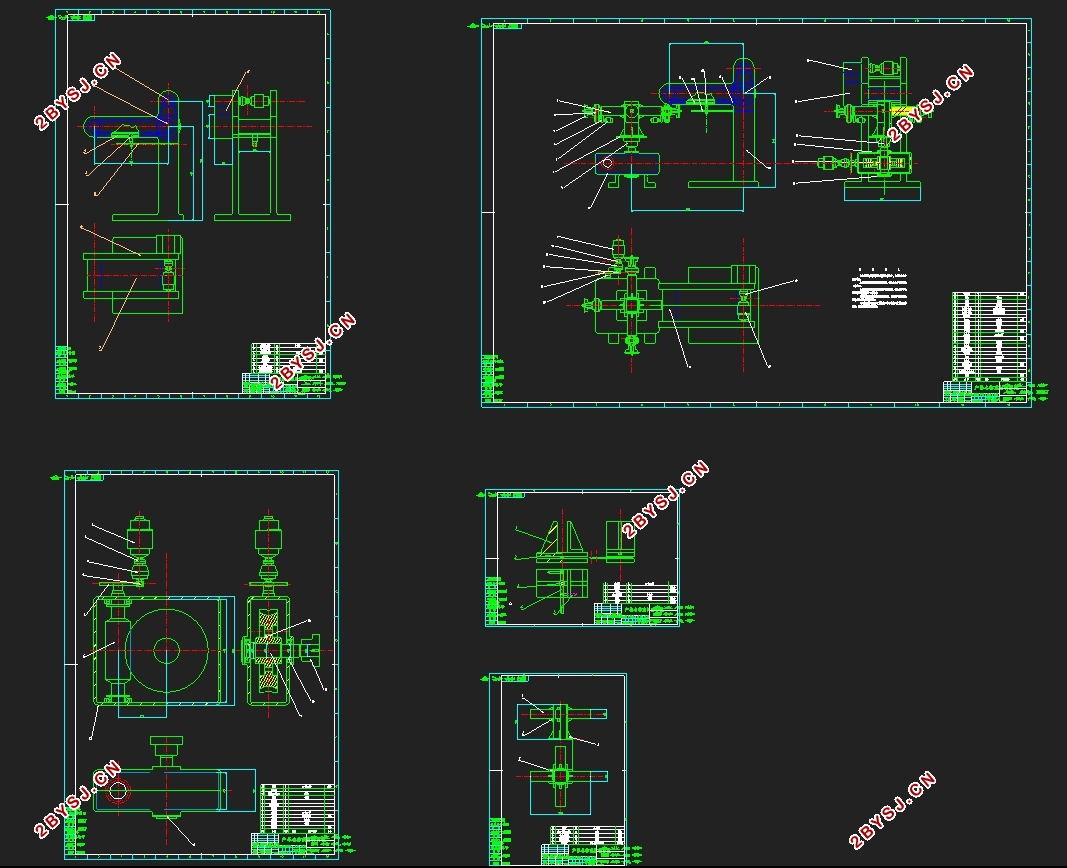

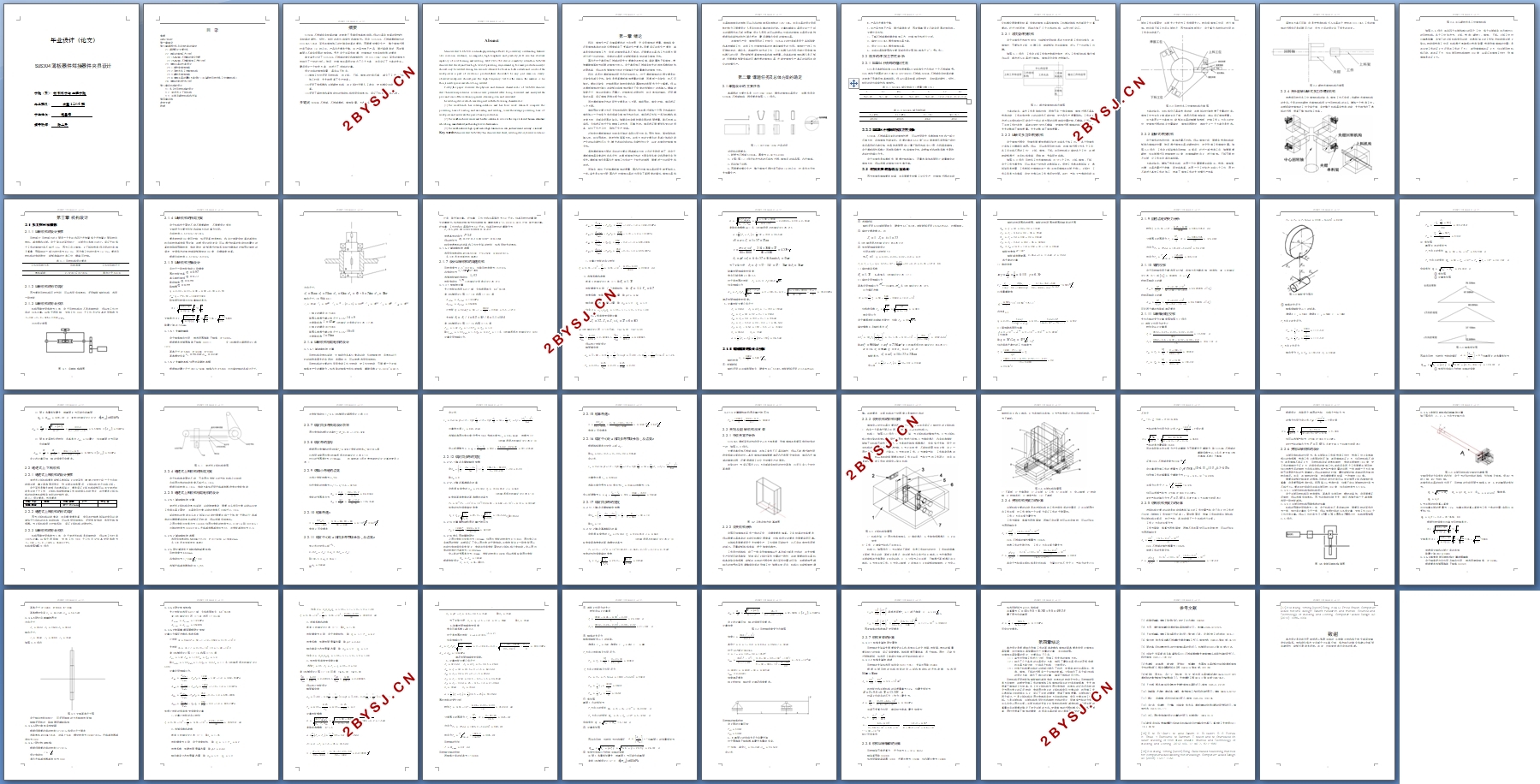

SUS304薄板器件焊接器件夹具设计(含CAD图)(任务书,开题报告,外文翻译,论文说明书11900字,CAD图5张)

摘要

SUS304不锈钢含有较高的镍,在室温下呈奥氏体单相组织。所以它具有较高的耐蚀性,有较高的塑性、韧性;较好的冷作成型性和焊接性。而由SUS304不锈钢薄板制作的HUL1245-1350C零件在焊接加工的时候有较高的要求:因需要规模化生产,整个焊接过程时间只能在10秒左右;产品内外要求平整;该产品为电子产品,需过高频测试,因此横截面上不能有明显的接合线。另外由于该零件较薄,对焊接的方法有较特殊的要求

本文首先讨论了SUS304不锈钢的理化和焊接特性,对HUL1245-1250C零件的焊接方法给出了一定的分析。然后,对焊接夹具设计给出了几个方案,并且论证了方案的优劣。

最后设计一个较优方案,并进行了详细的计算。

设计完成的焊接装置,具有以下特点:

(1) 焊接工作台采用回转机构,将上料、下料、焊接的时间压缩,减少了工件的平均加工时间,大大地提高了生产效率。

(2) 采用了传感器和夹钳翻转机构,在上料时无需人工参与,使机械化自动化程度提高。

(3) 采用了高转速和高传动比的传动机构利用伺服电机,保证了机构的运动精度。

关键词:SUS304不锈钢;不锈钢薄板;焊接装置;方案讨论

Absract

Stainless steel SUS304 containshighpercentageofNickl.It possessvery outstanding features like corrosion resistance, no-magnetie, high toughness and plasticity,etc.It also has excellent capablily of cold forming and welding. HUF1245-1350 device is made by ultra-thin SUS304 stainless steel sheets,and has high level of processing requirement.eg:for mass production need,it should only be welded during ten seconds.itshould be float on both outside and inside of the workpiece.as a part of electronic products,there shouldn’t be any jont seam on clearly observed.workpieces should pass the High Frequency Test.For the reason the material is too thin,it needs special care while bing welded.

Firstly,this paper discusses the physical and chemical characteristic of SUS304 stainless steel.Thenseverialprotential solutions were presented.After being discussed and analsysed the pros and cons of the solutions,a general idea was given and calculated.

he welding device which was designed with the following characteristics:

(1) The workbench has rotatinginstution and has four work station.It compress the possessing time of loading and unloading and welding, lower the average possessing time of workpiece and accelerate the pace of mass production.

(2) The workbench uses senser and has the instution to roll over the claps.it doesn’t human attendance while being manufactured,and has a high level of automation.

(3) The workbench uses high speed motors high transmission ratio,and movement accuracy is ensured.

Key words:Stainless steel SUS304;Thin stainless steel sheet; weldingdevice;discuss solutions.

目 录

摘要

ABSTRACT

第一章绪论

第二章课题任务及总体方案的确定

2.1课题设计主要任务

2.2 相关的焊接工艺分析

2.2.1 SUS304不锈钢的理化性质

2.2.2 SUS304不锈钢焊接工艺性分析

2.3 焊接夹具的方案设计

2.3.1 顺次型焊接机构

2.3.2 回转式多工位焊接机构

2.3.3 翻转式焊接机构

2.3.4 焊接夹具的最终方案设计(夹头翻转回转式多工位焊接机构)

2.4 焊接的理论变形分析

第三章各机构的设计

3.1多工位回转机构的设计

3.2 递进式上下料机构

3.3 夹钳及翻转机构和支架

第四章总结

参考文献

致谢