铁道捣固机机构设计(含CAD图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

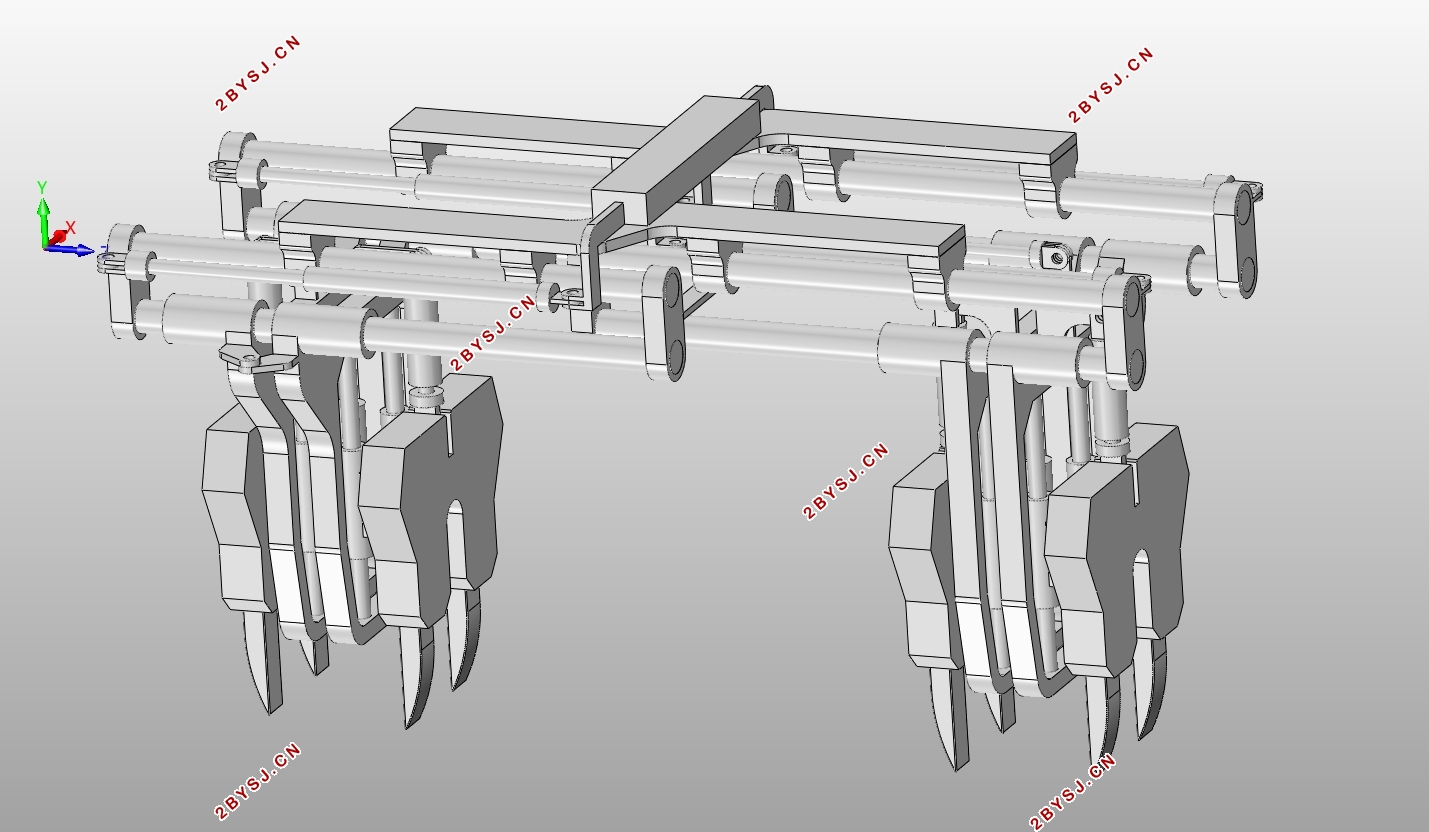

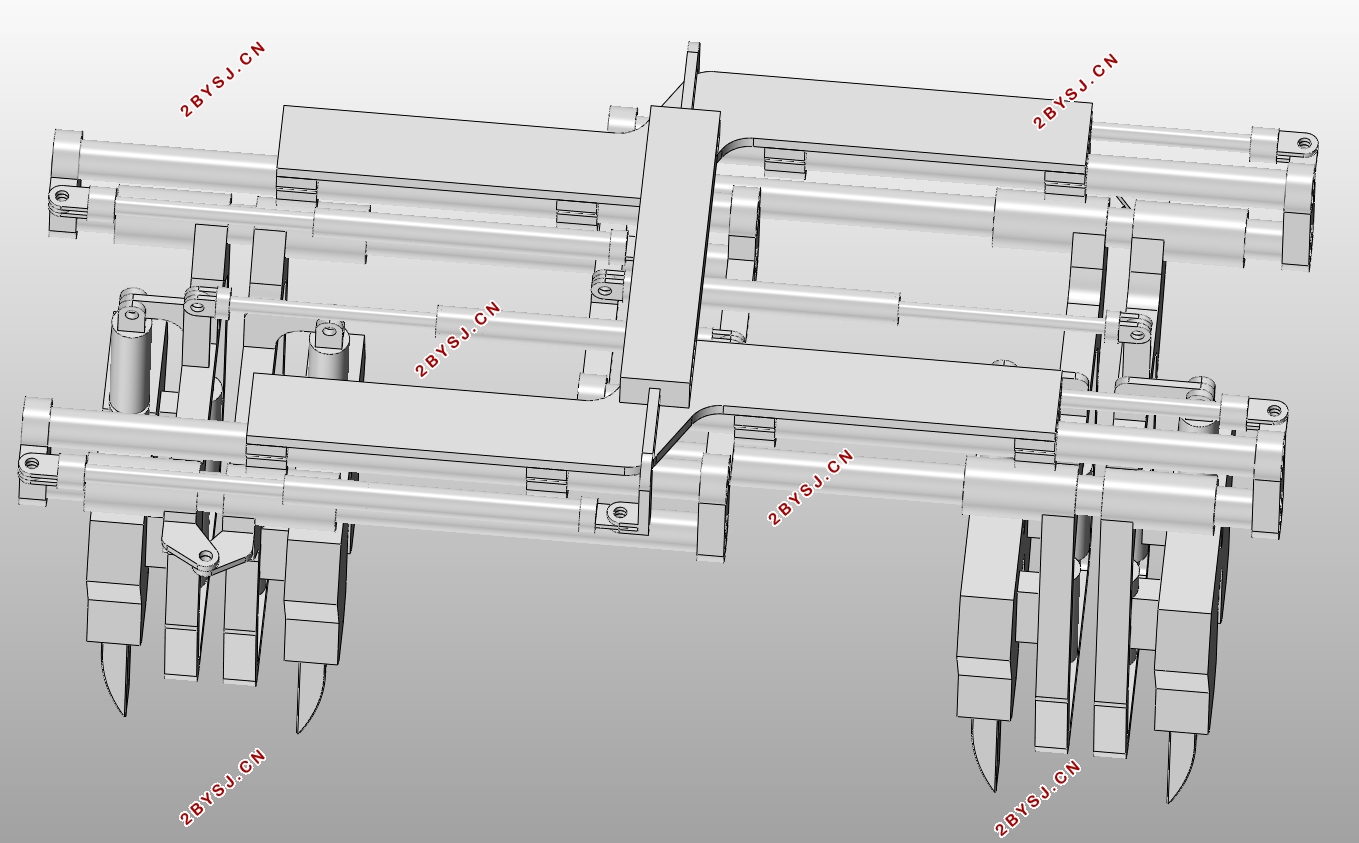

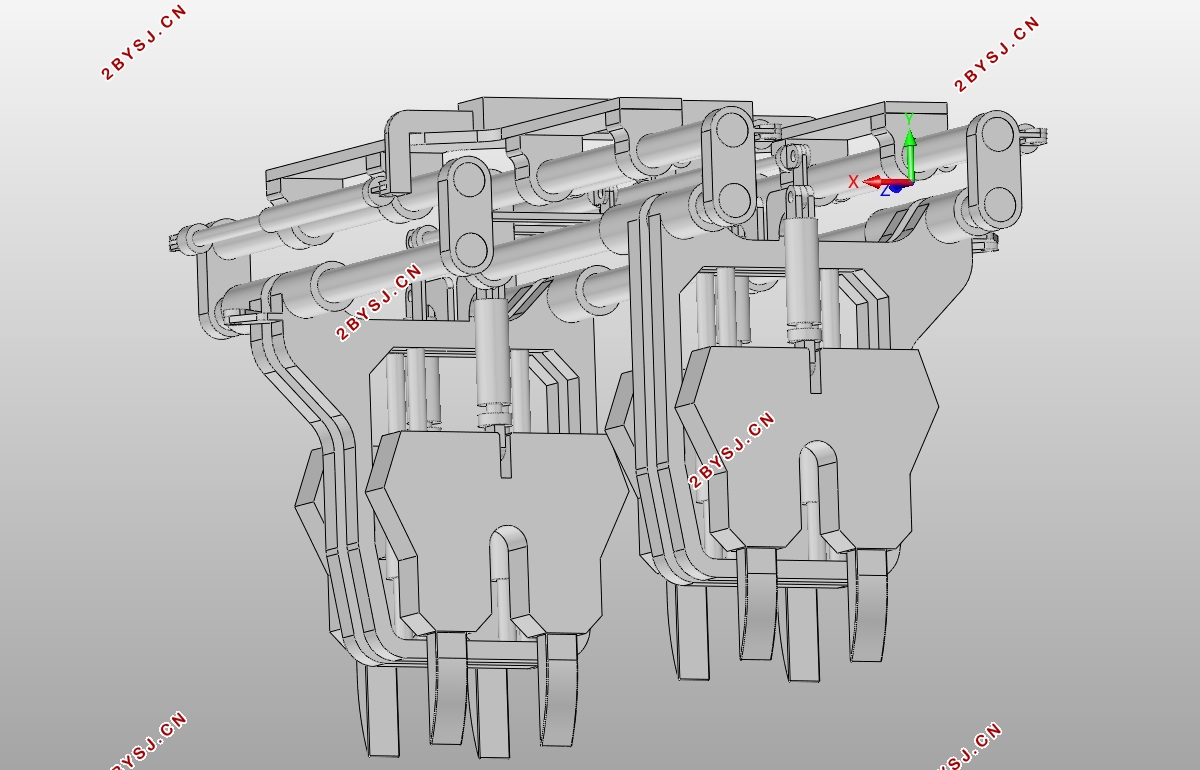

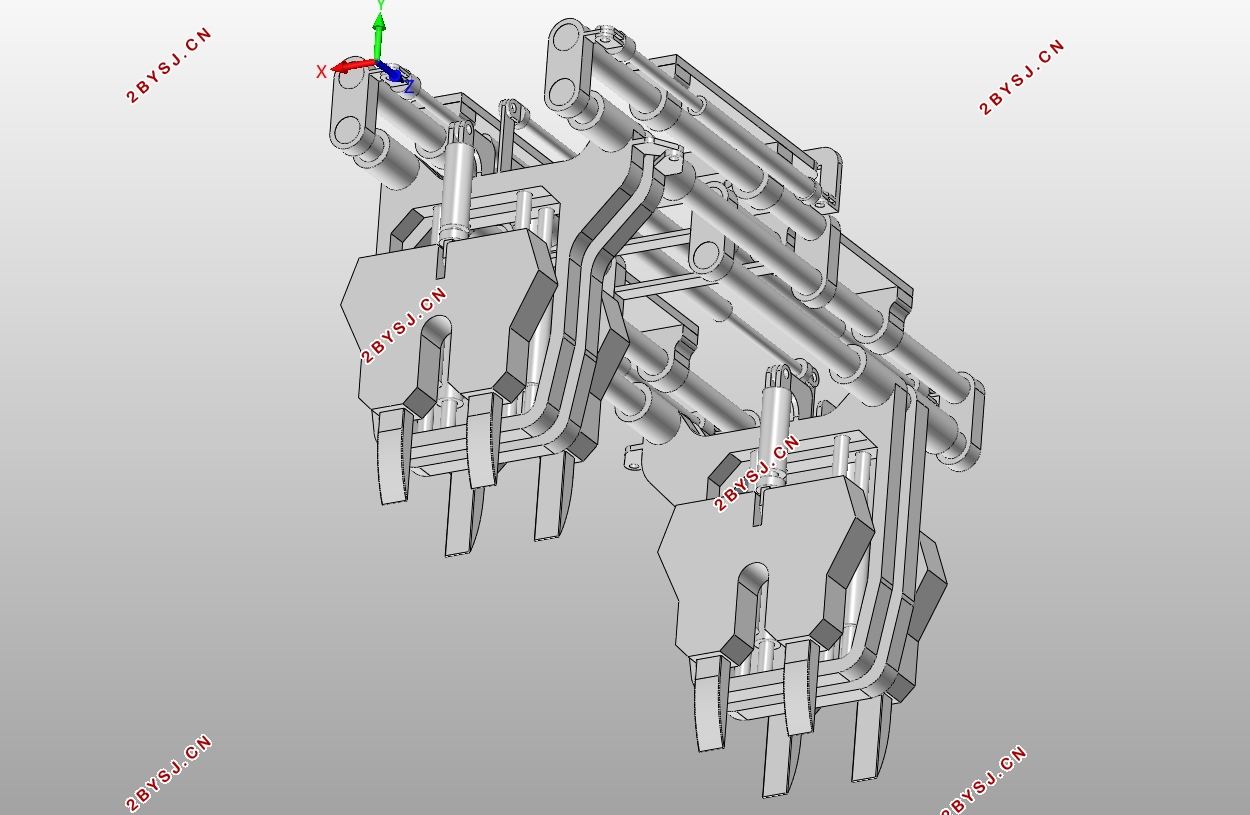

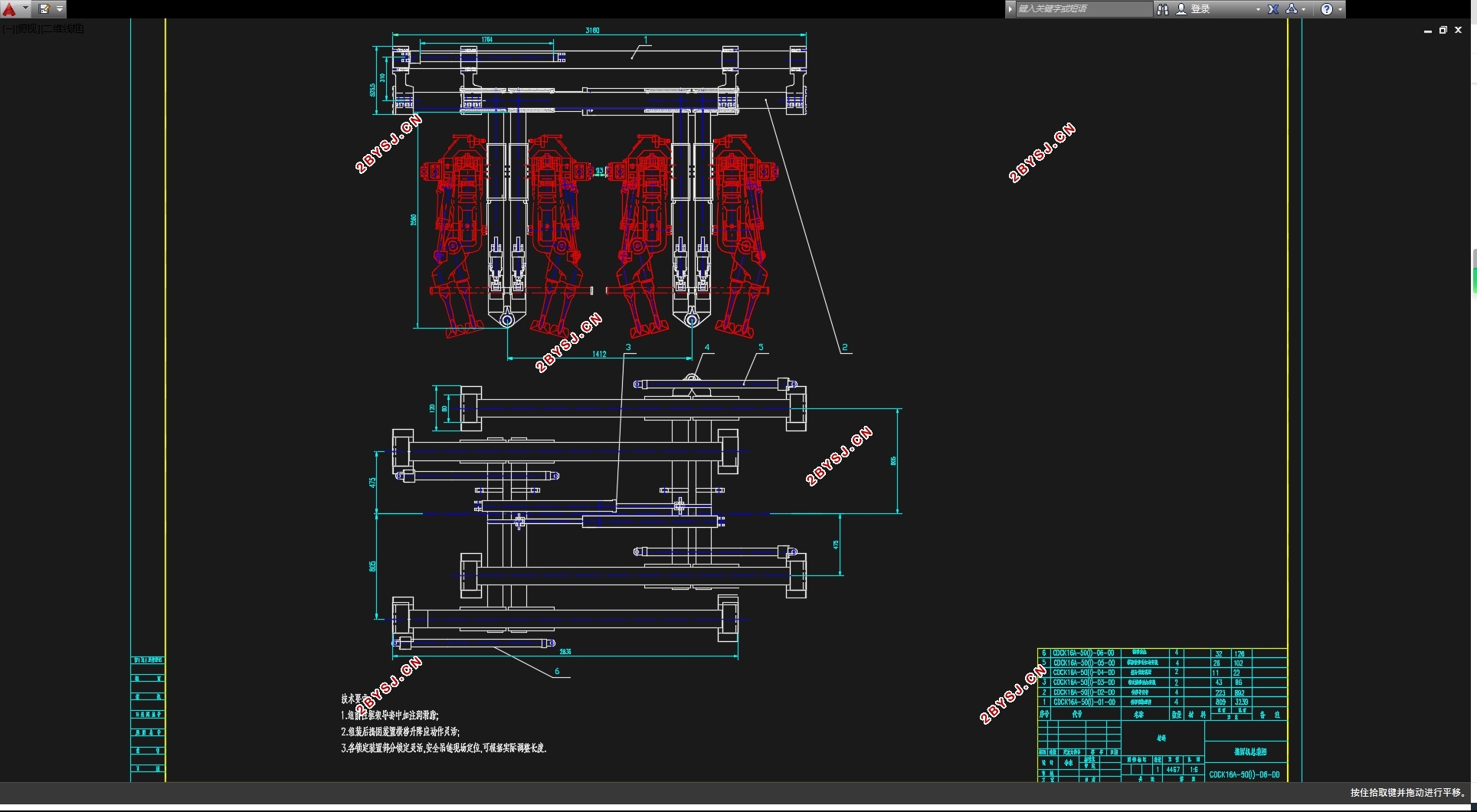

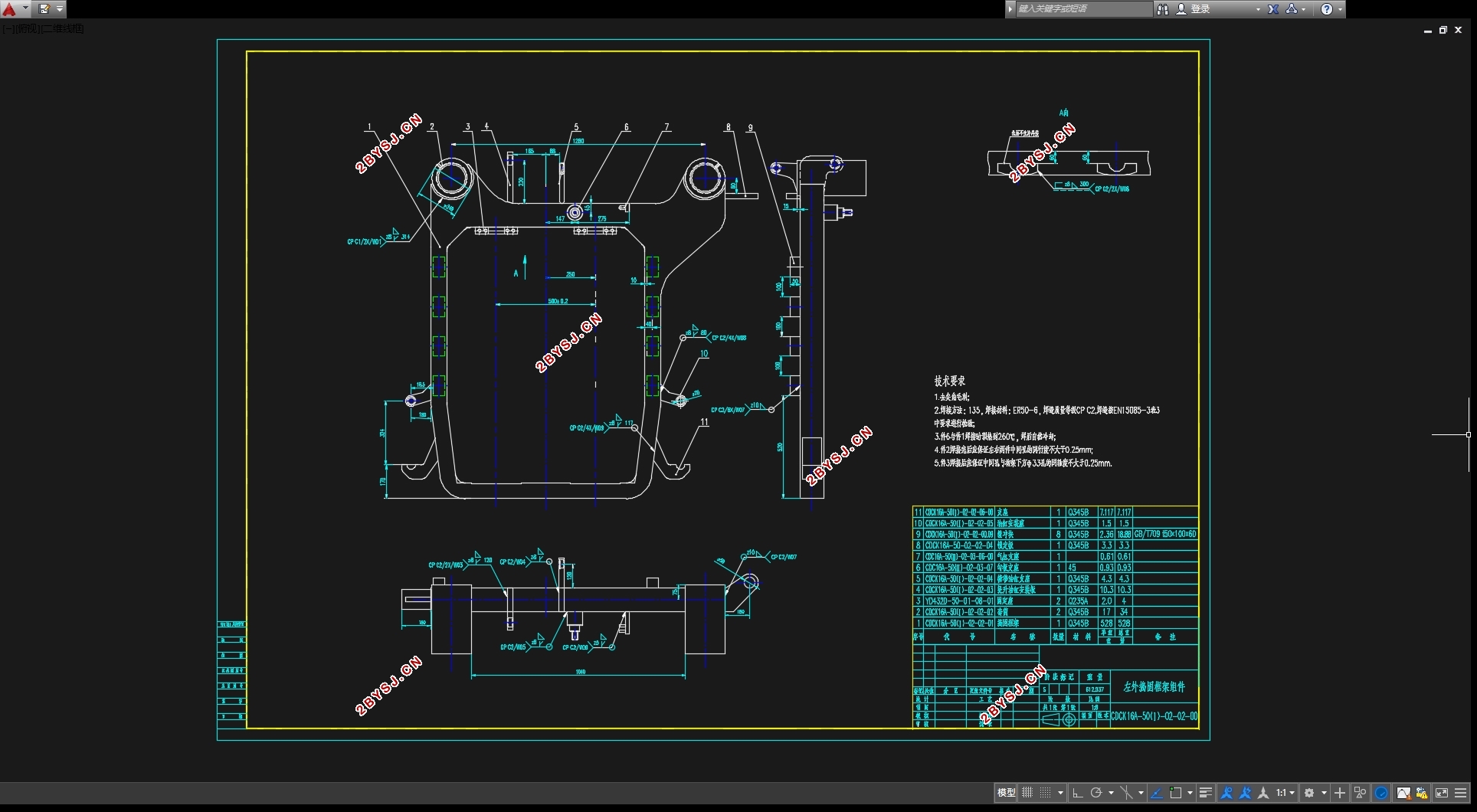

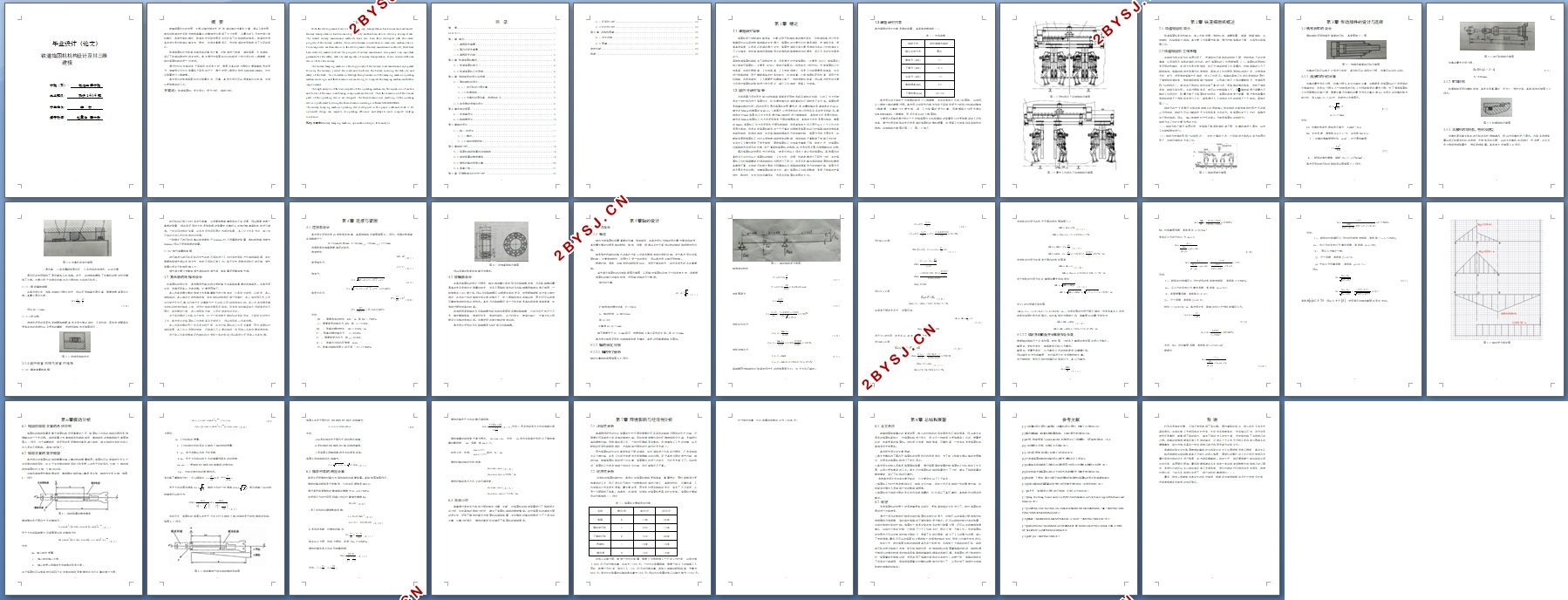

铁道捣固机机构设计(含CAD图,SolidWorks三维图)(任务书,开题报告,外文翻译,论文说明书9000字,CAD图4张,SolidWorks三维图)

摘 要

随着我国经济的发展,交通运输也越发先进,铁道运输作为重中之重,得以飞速发展,相关的铁道养护手段也随铁路事业的整体进步得到了充分发展,从最初的人力养护到小型机械化,再到大型机械化,铁道养护手段发展至今已经有了比较成熟的体系。铁道养护设备的进步是对铁道运输安全,稳定,快速的重要保证,也对铁道的使用寿命有了充足的保证。

铁道捣固机作为铁道养路设备的重中之重,对铁道进行拔道,道砟捣固,夯实道砟,保证了轨道的稳定性和安全性。本文通过对捣固机作业机构进行优化设计和三维建模,完成对捣固机构的进一步改进。

通过对作业机构的各个零部件的手里分析,推导出其运动方程和主要承载构件的受力,接着设计出作业装置各个零件的尺寸,通过使用三维设计软件SOLIDWORKS,对作业装置进行三维建模。

本文设计的铁道捣固机作业装置安全,可靠,其优化设计可以提高其作业效率,并适应更加复杂的工况。

关键词:铁道捣固机;优化设计;受力分析;振动分析。

Abstract

With the development of our country’s economy, transportation has become more advanced. Railway transportation has become a top priority and has been able to develop at a rapid rate. The related railway maintenance methods have also been fully developed with the overall progress of the railway industry, from initial human conservation to small-scale mechanization. From large-scale mechanization to the development of railway maintenance methods, there have been relatively mature systems.The progress of railway maintenance equipment is an important guarantee for the safety, stability and rapidity of railway transportation. It also ensures sufficient service life for the railway.

The railway tamping machine is the top priority of the railway road maintenance equipment. It ties up the railways, secures the roads and reinforces the ballast, ensuring the stability and safety of the track. This dissertation through the optimization of the tamping machine operating mechanism design and three-dimensional modeling, to complete the tamping mechanism further improvement.

Through analysis of the various parts of the operating mechanism, the equations of motion and forces of the main load-bearing components are derived. Then the dimensions of the various parts of the operating device are designed. The three-dimensional modeling of the operating device is performed by using the three-dimensional design software SOLIDWORKS. .

The railway tamping machine operating device designed in this paper is safe and reliable. Its optimized design can improve its operating efficiency and adapt to more complex working conditions.

Key words:railway tamping machine; optimization design; force analysis.

本次课题的设计对象是横移装置,其基本参数如表1.1:

表1.1技术参数

振动方式 连杆摇摆式振动

镐头夹持方式 异步

激振力(KN) 21

下插力(KN) 16.5

夹实力(KN) 13

激振频率(HZ) 63

下插深度(mm) 90-120

本次设计的主体在于对捣固机构进行三维建模,并在此基础上生成2D图纸,以实现从三维转二维的建模过程。本次设计的研究内容包括各个零部件受力分析和对机构的整体三维建模,计算部分主要为轴,梁,工作装置的受力计算,而建模部分则是先建立SOLIDWOEKS三维模型,而后生成CAD二维图纸。

主要设计思路是通过设计一个控制捣固作业机构横移的装置来应对更加复杂的工况和效率,通过对原有结构的优化来是减轻捣固机的整机质量,并提高工作效率和各零部件的寿命。

目 录

摘 要 I

Abstract II

第1章 绪论 1

1.1 课题研究背景 1

1.2 国内外研究背景 1

1.3课题研究内容 2

第2章 铁道捣固机概述 4

2.1 铁道捣固机简介 4

2.2铁道捣固机工作原理 4

第3章 传动部件的设计与选择 5

3.1横移油缸的设计 5

3.1.1 液压缸的行程计算 5

3.1.2 缸筒结构 6

3.1.3 活塞杆的导向套,密封和防尘 6

3.2 离合器的选择与设计 8

第4章连接与紧固 9

4.1 连接套设计 9

4.2 联轴器设计 10

第5章轴的设计 11

5.1 轴1的设计 11

5.1.1 概述 11

5.1.2 轴的强度校核 11

第6章振动分析 18

6.1 捣固机振动装置的总体结构 18

6.2 振动装置的数学模型 18

6.3 橡胶衬套的刚度计算 20

6.4 本章小结 21

第7章 环境影响与经济性分析 23

7.1 环保性分析 23

7.2 经济性分析 23

第8章 总结和展望 25

8.1 全文总结 25

8.2 展望 25

参考文献 26

致谢 27