转筒干燥机设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

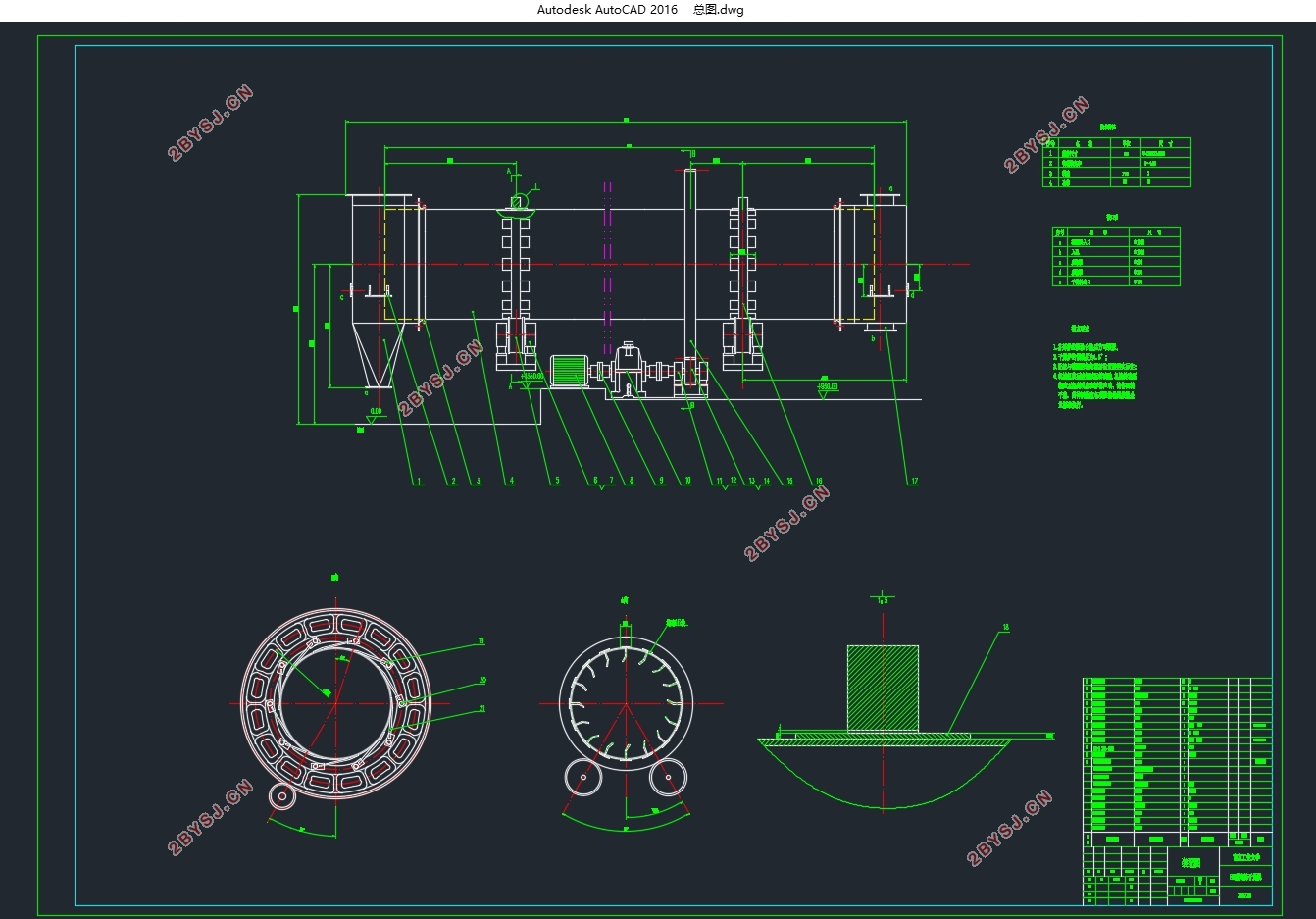

转筒干燥机设计(含CAD零件图装配图)(任务书,开题报告,论文说明书13000字,CAD图纸5张)

摘要

本文的主要内容关于转筒干燥机的设计,文章包括了对转筒干燥机的原理介绍、结构特点的解析、对干燥对象(一水硫酸镁)的经济性分析以及转筒干燥机主要部件的设计计算。

文章的第一、二章大概地介绍了转筒干燥机工作原理、特点以及其在工业生产的作用,转筒干燥机由回转筒体、托轮挡轮等支承装置、减速器齿圈等传动装置组成。整个干燥过程在回转筒体内完成,干燥对象随着回转筒体的转筒,在抄板的作用下从进料口向出料口传输,干燥介质物料在物料传输的过程与物料接触,实现热量与水份的转换,完成干燥的过程。转筒干燥机有着处理能力大、产量高、干燥成本低、适应性强等众多优点,目前被广泛地应用于化工、建筑、食品等多个行业。但与此同时,转筒干燥机也存在着设备系统庞大、占地面积大等缺陷,仍需要改进,目前正朝着精密化、操作简便化、智能化的方向发展。

文章的第三章介绍了本次设计的干燥对象(一水硫酸镁)的用途以及发展趋势,并对其进行经济性分析。根据数据表明,我国当前6%的耕地面积存在严重缺镁的状况,镁、硫元素在畜牧业、农业中的用途也十分广泛,一水硫酸镁可以用作复肥添加剂、动植物饲料添加剂等等,目前全国对一水硫酸镁的需求量远远地超过了产量。因其成本低、经济性效益高等特点,一水硫酸镁的用途将被进一步开发,有着广阔的发展前景。

文章的第四、五章是关于转筒干燥机设计计算的过程,第一步根据任务书中的产量及干燥对象的性质计算出干燥过程中所需要的热量,从而确定出干燥过程出需要的空气的量。第二步根据空气的量确定出回转筒体的直径及长度并根据物料的腐蚀性等特点选择筒体材料。第三步估算出筒体的重量,计算设计出滚圈、托轮的结构,进一步确定出挡轮的结构。第四步根据筒体的直径确定出回转筒体最合适的转速,从而确定传动比、齿圈和齿轮的计算、电动机和减速器的选择等等。最后一步完成了对转筒干燥机安装要求说明以及密封装置、进料口、出料口的说明。

关键词:转筒干燥机、一水硫酸镁、干燥技术

Design of a rotary dryer

Abstract

The main content of this paper is about the design of a rotary dryer. The article includes the introduction of the principle of the dryer, the analysis of the structural features, the economic analysis of the drying object (a water Magnesium Sulfate) and the design and calculation of the main components of the dryer.

The first, second chapter of the paper introduces the working principle and characteristics of the rotary dryer and its role in industrial production. The dryer is composed of a rotary drum, a supporting gear, a gear wheel and a gear ring. The whole drying process is completed in the rotary barrel, and the drying object is transferred from the inlet to the outlet with the rotating cylinder of the rotary barrel. The drying medium material is in contact with the material in the process of material transmission, and the heat and water are converted and the drying process is completed. Rotary dryer has many advantages, such as large processing capacity, high production, low drying cost and strong adaptability. It is widely used in many industries, such as chemical industry, construction, food and so on. At the same time, the drum dryer also has the defects of large equipment and large area, and it still needs improvement, and it is developing towards the direction of precision, simple operation and intelligent.

The third chapter introduces the use and development trend of the dry object (Magnesium Sulfate), and analyzes its economy. According to the data, 6% of the current land area in China is seriously deficient in magnesium. The use of magnesium and sulfur in animal husbandry and agriculture is also very wide. One water Magnesium Sulfate can be used as compound fertilizer additive, animal and plant feed additive and so on. At present, the demand for one water Magnesium Sulfate is far more than the production in the country. Because of its low cost and high economic efficiency, the use of Magnesium Sulfate will be further developed and has broad prospects for development.

The fourth, fifth chapter of the article is about the design and calculation of a rotary dryer. The first step is to calculate the amount of heat needed in the drying process according to the output of the task book and the nature of the drying object, so as to determine the amount of air needed in the drying process. The second step is to determine the diameter and length of the rotary cylinder according to the amount of air and select the cylinder material according to the corrosiveness of the material. The third step is to estimate the weight of the cylinder, calculate and design the structure of the rolling ring and supporting wheel, and further determine the structure of the retaining wheel. The fourth step is to determine the most suitable rotational speed according to the diameter of the barrel, so as to determine the transmission ratio, the calculation of the gear and gear, the selection of the motor and the reducer, etc. Finally, the installation requirements for rotary dryer and the instructions for sealing device, feeding port and discharge port are completed.

Key words: rotary dryer, Magnesium Sulfate water, drying technology

目录

第一章 引言 1

第二章 干燥技术介绍 2

2.1干燥机的工作原理 2

2.2干燥机大致的几种类型 2

2.3干燥机的特点 2

2.4干燥机的结构名称 2

2.5干燥机的国内外发展现状 3

2.5.1直接加热式干燥机 3

2.5.2间接加热式干燥机 5

2.5.3复合加热式干燥机 6

2.6干燥机发展趋势 6

第三章 一水硫酸镁的性能和用途 8

3.1一水硫酸镁的性质 8

3.1.1化学式 8

3.1.2性质 8

3.2一水硫酸镁的用途 8

3.2.1作复肥干燥剂 8

3.2.2作农肥 8

3.2.3作饲料添加剂 9

3.3一水硫酸镁的发展趋势 9

3.3.1我国目前的对的一水硫酸镁需求情况 9

3.3.2我国一水硫酸镁发展现状 10

3.3.3硫酸镁的发展前景 10

3.4一水硫酸镁的发展建议 11

第四章 一水硫酸镁转筒干燥机的设计计算 12

4.1任务书条件 12

4.2物料衡算和热量衡算 12

4.2.1水分的蒸发量: 12

4.2.2空气消耗量计算 13

4.3转筒干燥机参数计算 14

4.3.1回转筒体的直径D 14

4.3.2容积传热系数aa 14

4.3.3回转筒体长度Z 14

4.3.4 回转转筒转速n、安装角度和斜率S的选择 16

4.3.5 干燥对象在筒体内的停留时间 16

4.3.6回转筒体填充率计算 16

4.4回转筒体设计 17

4.4.1筒体最小壁厚的计算 17

4.4.2筒体载荷计算 17

4.4.3 筒体弯矩与应力计算 18

4.4.4筒体变形计算 19

4.4.5截面变形的筒体计算 20

4.4.6筒体热膨胀伸长计算 21

4.5滚圈设计 21

4.5.1滚圈与托轮材料 21

4.5.2滚圈、托轮接触应力计算与校核 22

4.5.3校核弯曲应力 23

4.6托轮及轴承计算 23

4.6.1托轮设计 23

4.6.2 托轮轴设计计算 24

4.6.3滚动轴承计算 25

4.6.4轴的弯矩核算 25

4.7挡轮及轴的计算 26

4.7.1挡轮 26

4.7.2挡轮受力计算 26

4.7.3挡轮参数的确定 26

4.7.4挡轮轴及轴承的选择 27

4.8 传动比设计 28

4.8.1传动功率的确定 28

4.8.2传动装置的确定 30

4.8.3齿轮的计算 30

4.9转筒干燥机试机及使用注意事项 31

第五章 回转圆筒的进出料、润滑及密封 34

5.1转筒干燥机的进出料 34

5.1.1进出料 34

5.1.2进出料箱 34

5.2 润滑系统 34

5.2.1 滚圈、托轮、齿圈等传动装置的润滑 34

5.2.2 减速器的润滑 34

5.3 密封装置 34

5.4经济性分析 35

5.5结语 35

参考文献 36

致 谢 38