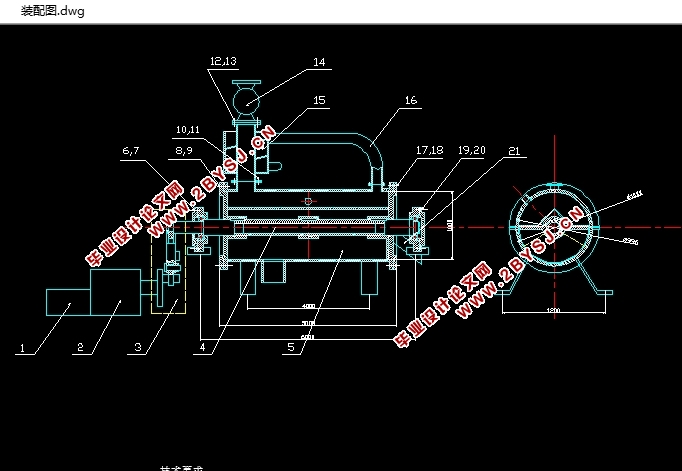

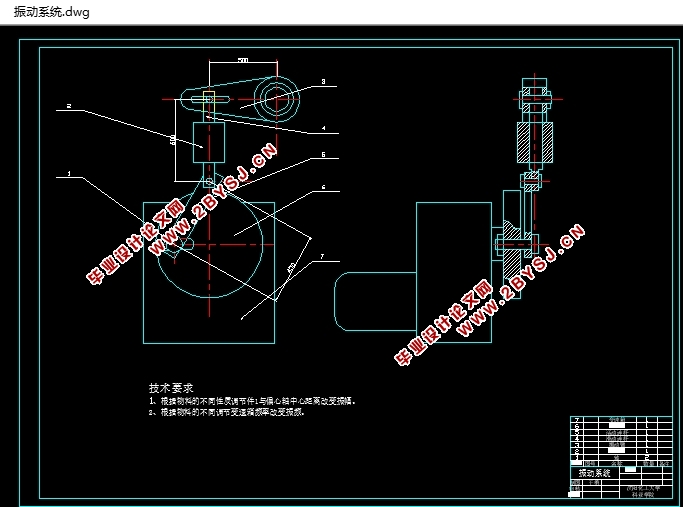

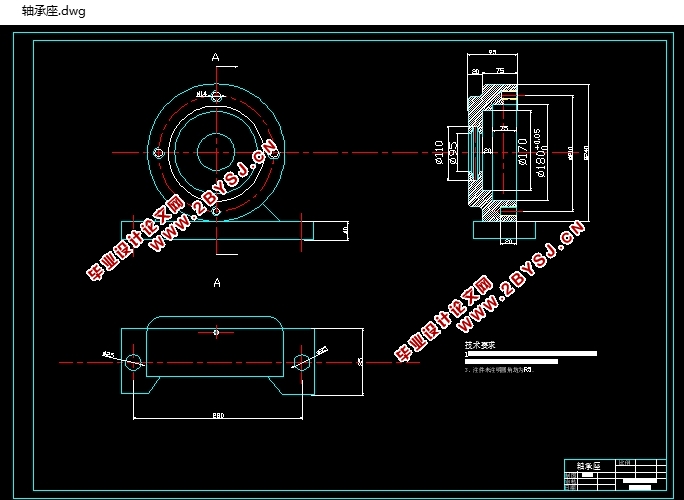

振动流化床干燥机的设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

振动流化床干燥机的设计(含CAD零件图装配图)(论文说明书16000字,文献综述,CAD图纸3张)

摘要

在60年代末70年代初期发展了一种卧式多室流化干燥器。这种设备结构简单,操作方便,适用于各种难干燥的粉粒状物料和热敏性物料的干燥。如聚乙烯、农药、人造肉、硫酸铜、食盐等。但卧式多室流化干燥器的热效率比多层流化床干燥器低,尤其是在采用较高热空气温度时其热效率将显得更差。随着应用技术的不断发展,流化床干燥器的型式及应用也越来越多,设备的分类方法也有所不同。多年来,流化床干燥器在工业上有许多应用。流化床干燥器是近年来发展的一种新型高效干燥器。目前在化工、轻工、医药、食品等工业中已广泛应用,而且已逐步推广到造粒、煅烧、冷却等方面。干燥时由于气固两相逆流接触,剧烈搅动。固体颗粒悬浮于干燥介质之中,具有很大的接触表面积,无论在传热、传质、容积干燥强度、热效率等方面都很优良。流化床干燥器操作简单,劳动强度低,劳动条件好,检修方便,运转周期长。由于床层温度平稳,干燥效果亦好。目前应用最广的卧式振动流化床干燥器,形状和基本结构与普通卧式流化床干燥器很相似。筛板在圆筒箱体内与箱体中心为轴做左右上下振动,物料在筛板上在振动的作用下做上抛翻转循环运动和向出口端直线运动。物料依靠机械振动和穿孔气流双重作用流化。

关键词: 振动硫化床; 振动; 干燥

Abstract

In the late 1960s early 1970s the development of a multi-room horizontal flow of driers. This simple structure of equipment, easy to operate, difficult to apply to a variety of dry powder materials and granulose Reminxing materials dry. But horizontal flow more room than the thermal efficiency of dryers fluid bed dryers multi-storey low, especially in a hot air temperature, the higher thermal efficiency will be even worse. With the continued development of applied technology, fluid bed dryers patterns and applications is also increasing, equipment classification is different. Over the years, fluid bed dryers have many applications in industry, such as single cylinder-shaped fluid bed, multi-storey cylinder-shaped fluid bed dryers, fluid bed dryers horizontal multi-room, a blender fluid bed, inert particles fluid bed, vibration fluid bed. Fluid bed dryers is a new development in recent years, efficient dryers. Currently in the chemical industry, light industry, medicine, food and other industries has been widely applied, but has gradually extended to Zaoli, calcine, cooling and so on. Dry because Qiguliangxiang current contact dramatic mix. Solid particles suspended in the dry medium, the contact surface is significant, both in heat transfer, transmission quality, volume dry strength, thermal efficiency aspects are fine. Fluid bed dryers operate simple, low labor intensity, good working conditions, overhaul facilities functioning cycle long. The bed-temperature stable, dry results also good. Currently the most widely applied horizontal vibration fluid bed dryers, and the basic structure and shape of the ordinary horizontal fluid bed dryers very similar. The difference is that the entire fabric through the spring-loaded support on the base, a material-tilted slightly porous panels, fabric side or on both sides with the electrical vibration. Materials rely on mechanical vibration and perforation of the dual roles of the flow of air currents, and vibration role in the forward movement

Key words : Vibrating desiccation of bed ; Vibrarate ; Oscillation

设计原理

振动通过流化床流化床吸收和振动流化床卧室设计的优点的滚筒设计原理,其工作原理是筛板在气缸壳体和外套轴向载荷或振动,出口和入口端的中心筛板成向下倾斜5°角,材料土地上筛板从入口处,在振动的作用下,围绕在一个筛板,做圆周运动和朝向出口端直线运动投翻转。使材料接触到热空气充分接触,以使不同的材料,以达到干燥的效果最好。通过调整变速箱和偏心锯的距离来改变振动频率和幅度。通过热交换器浪费废气的热量的材料预热,最小化的废热。

4.2计算条件

物料名称:谷物

生产能力Gc:3000kg/h

含水量:湿料 1.5%(干基)

干料 0.2%(干基)

固体颗粒临界含水量为1.5%,平衡水分不计 平均颗粒直径

目 录

第一章绪论……………………………………………………………2

1.1干燥技术的概述……………………………………………………2

1.2干燥过程中物料的性质……………………………………………3

1.3干燥技术的发展前景………………………………………………4

第二章流化床干燥机的概述…………………………………………8

2.1流化床干燥技术的发展历史………………………………………8

2.2流化过程的基本概念………………………………………………11

2.3流化床干燥机的基本结构………………………………………13

2.4流化床干燥机的总类……………………………………………15

第三章 振动流化床干燥……………………………………………16

3.1振动流化床技术发展过程………………………………………19

3.2振动流化床干燥机原理与结构…………………………………19

3.3振动流化床干燥机主要特点……………………………………19

3.4振动流化床的用途………………………………………………20

3.5振动流化床干燥器的分类………………………………………20

第四章 设计计算………………………………………………………22

总结 ……………………………………………………………………26

参考文献 ………………………………………………………………27

致谢 ……………………………………………………………………28