基于双阀芯阀的振动挖掘液压系统设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

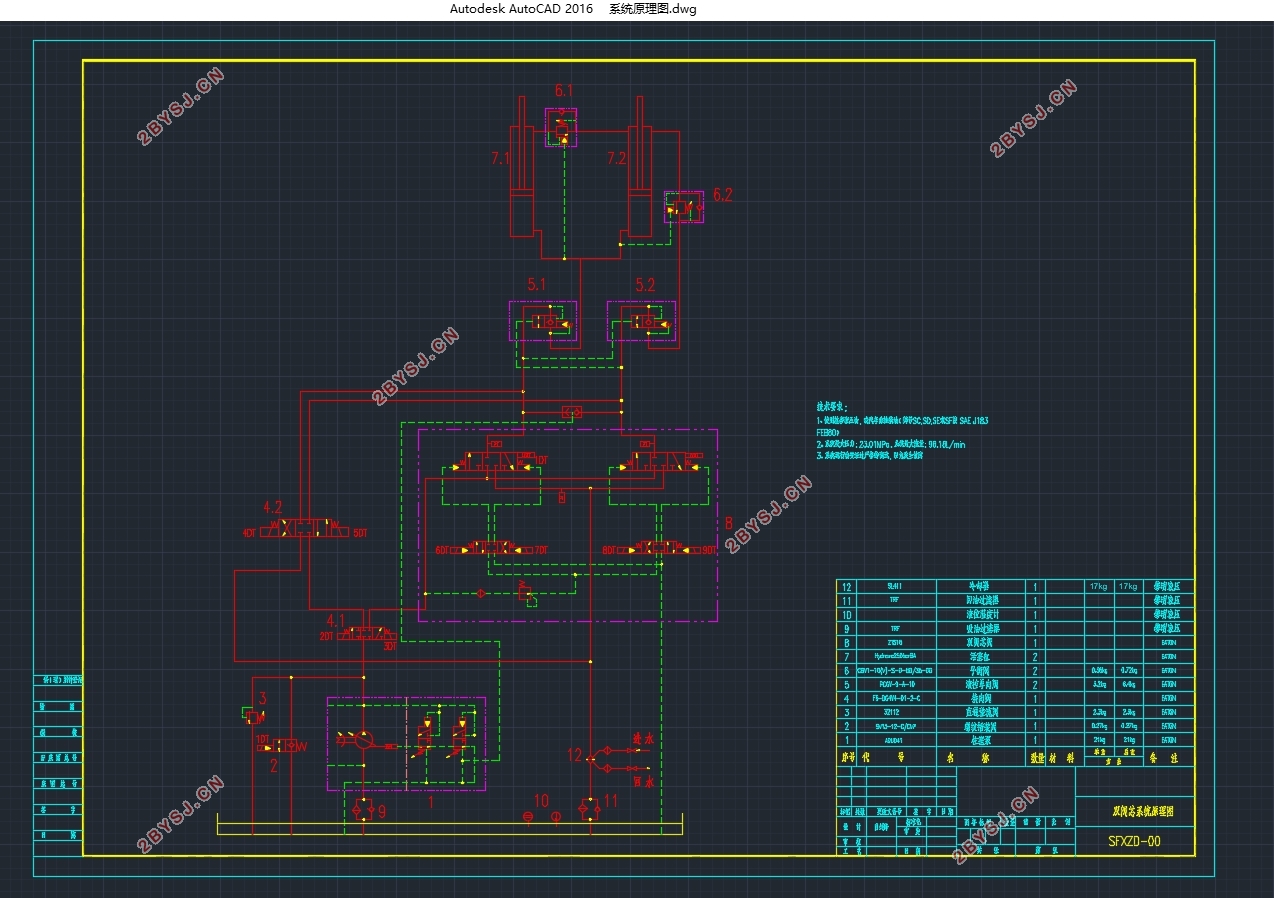

基于双阀芯阀的振动挖掘液压系统设计(含CAD图)(任务书,开题报告,论文说明书11000字,CAD图4张)

摘要

随着经济的高速发展,人类对于资源的需求越来越大,海洋资源已经成为人类开采资源的重要来源。虽然海底土壤中含有大量人类所需的资源,但海底地形复杂,工况多变,土壤软硬程度不一,想要高效开采海洋资源并不简单。本文的目的便是设计一种能适应硬质土壤的振动挖掘液压系统,应用于海底资源的开采。

本文设计的一种基于双阀芯阀的振动挖掘液压系统,首先通过对国内外振动挖掘技术发展现状的探讨,发现振动挖掘能在很大程度上减小挖掘阻力,对于振动挖掘技术运用于抓斗的研究很有必要。随后研究了伊顿公司的ZTS16双阀芯阀的工作原理、双阀芯阀的工作特点以及控制方式。然后基于对挖掘抓斗的功能需求,完成总体液压原理图的设计。然后分析抓斗的工况,分析抓斗的实际挖掘力和实际的挖掘速度,根据工况条件选择合适的执行元件,计算得出系统最大工作压力和最大流量,选择满足条件的柱塞泵、电动机和液压阀。最后进行非标准元件的设计,包括油箱和动力站的结构设计以及管路的设计计算。

本设计中基于双阀芯阀的振动挖掘液压系统能让抓斗在实际中应对不同的工况,从而让抓斗在开采海洋资源中既能抓取硬质土壤资源,又能抓取非硬质土壤资源。论文根据实际工况来选择液压元件,并且完成了非标准元件的设计以及动力站的布置。

关键词:双阀芯阀;振动挖掘;负载敏感泵;液压系统

Abstract

With the rapid development of the economy, human beings have more and more demand for resources, and marine resources have become an important source of human resources. Although the seabed soil contains a lot of resources needed by humans, the seabed topography is complex, the working conditions are changeable, and the soil is soft and hard. It is not easy to efficiently exploit marine resources. The purpose of this paper is to design a vibration excavation hydraulic system that can adapt to hard soil and apply it to the exploitation of seabed resources. .

This paper designs a vibration excavation hydraulic system based on double-valve valve. Firstly, through the discussion on the development status of vibration excavation technology at home and abroad, it is found that vibration excavation can greatly reduce the excavation resistance, and the vibration excavation technology is applied to grasp Fighting research is necessary. Then I studied the working principle of Eaton’s ZTS16 double spool valve, the working characteristics of the double spool valve and the control method. The overall hydraulic schematic is then designed based on the functional requirements of the excavation grab. Then analyze the working condition of the grab, analyze the actual digging force of the grab and the actual excavation speed, select the appropriate actuator according to the working conditions, calculate the maximum working pressure and maximum flow of the system, select the plunger pump that meets the conditions, Motor and hydraulic valve. Finally, the design of non-standard components, including the structural design of the fuel tank and power station and the design calculation of the pipeline.

The vibration excavation hydraulic system based on the double valve core valve in this design can make the grab handle different working conditions in the actual situation, so that the grab can capture hard soil resources and capture non-hard in the exploitation of marine resources. Quality soil resources. The paper selects the hydraulic components according to the actual working conditions, and completes the design of the non-standard components and the layout of the power station. .

Key words: Double spool valve; Vibration mining; Load sensitive pump; Hydraulic system

工况分析

图2.1 抓斗工作原理图

基于双阀芯的振动挖掘液压系统的抓斗结构简图如图2.1所示,两瓣抓斗分别由两个双作用活塞液压缸驱动,液压缸无杆腔进油时,活塞杆伸出,推动抓斗闭合。之所以这样设计,是因为无杆腔面积较大,更易产生较大推力。

2.1工作条件的确定

查阅相关资料,当抓斗用于硬质土壤的挖掘时,其工作条件如表2.1所示:

表2.1 工作条件

最大负载 挖掘速度

280kN 4m/min

即两个活塞缸受到的最大外力均为280kN,活塞缸的运动速度为4m/min。

目 录

第1章 绪论 1

1.1设计背景和意义 1

1.2振动挖掘技术研究现状 1

1.3 Eaton公司的Ultronics ZTS16双阀芯阀 2

1.3.1概述 2

1.3.2 ZTS16双阀芯阀的特点 3

1.3.3产品规格参数 3

1.3.4工作原理 4

1.4论文研究的主要内容 4

1.4.1基本内容 4

1.4.2技术路线 5

第2章 工况分析 7

2.1工作条件的确定 7

2.2负负载的平衡 7

2.3液压锁的设计 8

第3章 系统原理图的拟定 10

3.1双阀芯振动挖掘液压系统原理图的绘制 10

3.2功能实现 12

第4章 液压元件的选型计算 13

4.1活塞缸的选型 13

4.2反算系统压力 13

4.3泵的选型 14

4.4原动机选型 15

4.5阀的选型 15

第5章 油箱和管路的设计 19

5.1油箱的设计 19

5.1.1总体尺寸的确定 19

5.1.2相关辅件的选择 20

5.2管路的设计 21

第6章 经济性分析 22

第7章 总结与展望 23

参考文献 24

致 谢 25