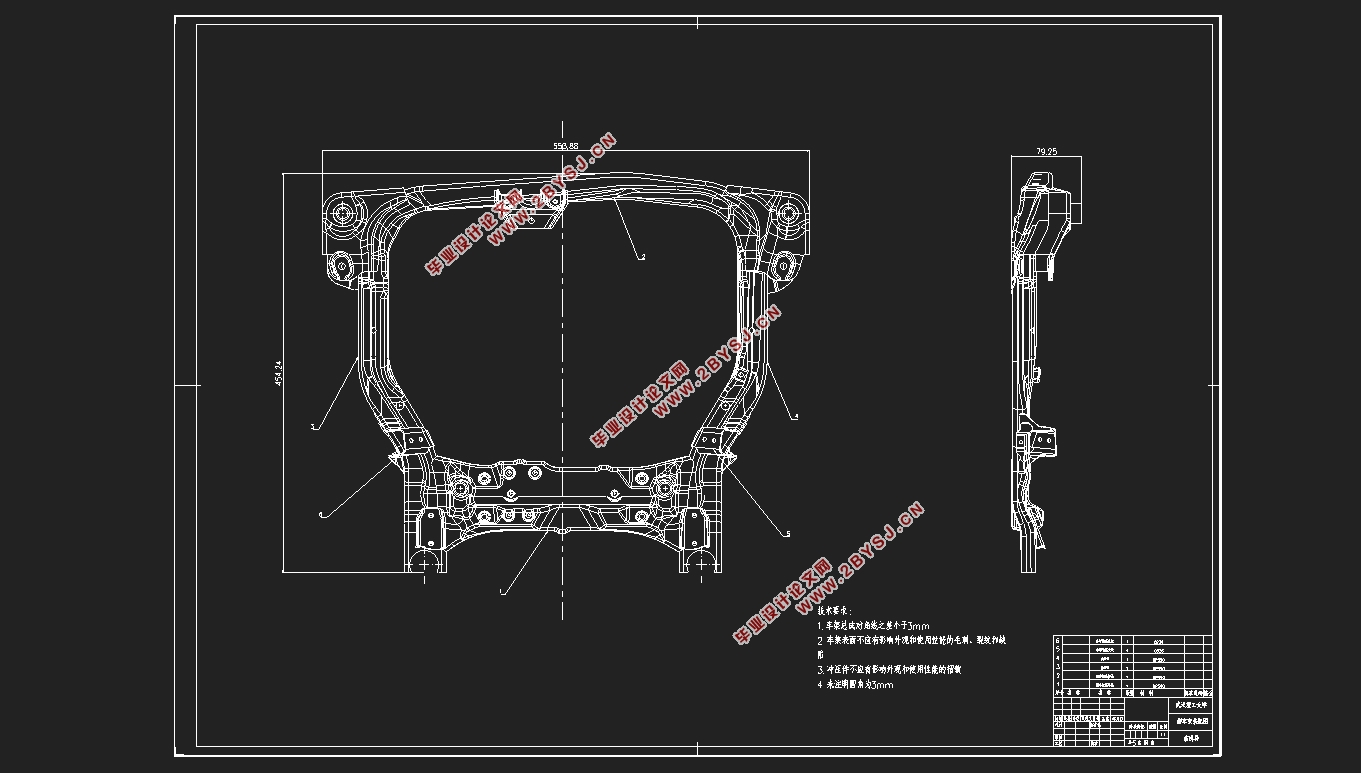

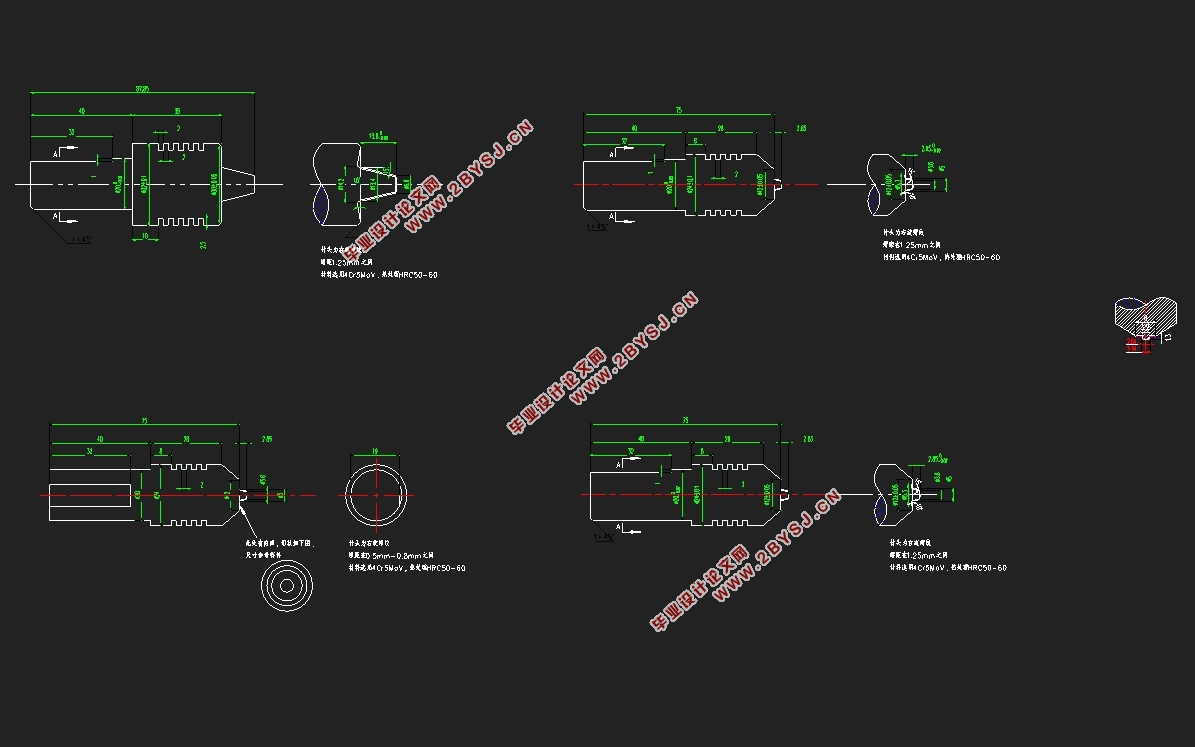

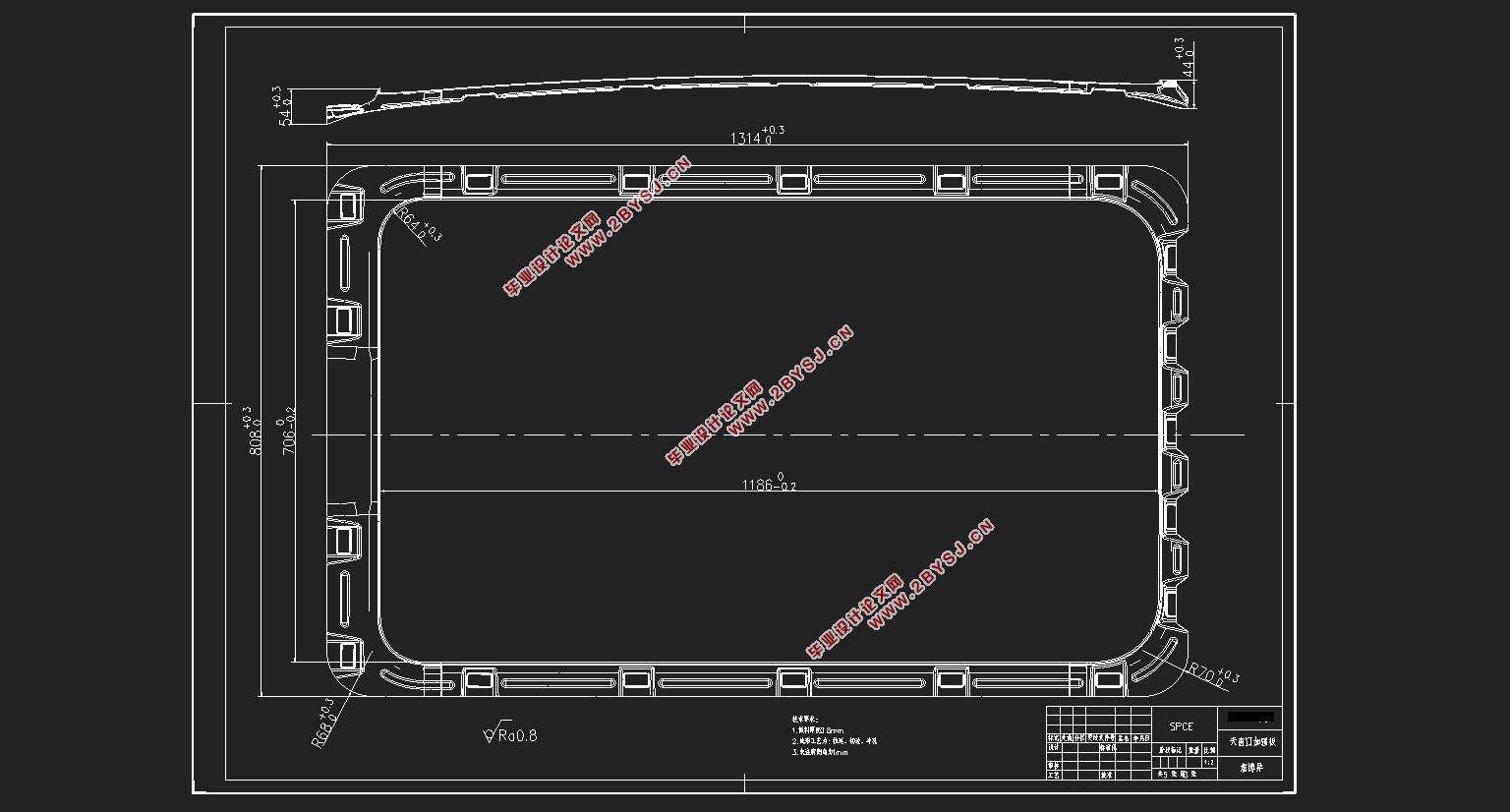

本田钢铝复合副车架轻量化连接技术(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

本田钢铝复合副车架轻量化连接技术(含CAD零件图装配图)(任务书,开题报告,文献摘要,外文翻译,论文说明书23000字,CAD图5张)

摘要

泡沫铝三明治板(Aluminum Foam Sandwich,AFS)是一种优秀的轻量化结构,具有质轻、高比刚度、高阻尼、吸能吸声等优异性能,广泛应用于航天、航空、汽车、船舶、建筑等行业。本项目研究了采用搅拌摩擦焊工艺制备的AFS的微观组织和力学性能,并使用ABAQUS模拟了AFS的动态压缩压缩性能,研究了孔隙率和孔径大小对AFS压缩性能的影响以及使用ANASY模拟了焊接过程中非镀锌DP590高强钢-铝搅拌摩擦焊搭接接头的温度场的变化。

研究发现,在高温下,预制体具有良好的变形能力,当加热温度为450℃时,其延伸率能达到17.5%,相较于泡沫铝的变性能力在10%以内,这为制备形状较为复杂的AFS结构的零件提供了可能性。运用搅拌摩擦焊工艺成功制备出异形泡沫铝“三明治”结构,成功实现了泡沫铝和钢的连接。通过对钢-铝结合界面的观察,发现焊核区非镀锌钢-铝接头的结合方式为机械结合+冶金结合,而焊核区外界面处不存在IMC层,钢-铝间仅通过相互嵌入来实现机械结合。非镀锌钢-铝接头IMC层较薄,仅为1~3µm,界面结合面积较小。而且在其机械结合界面处可能存在微裂纹等缺陷,这些缺陷进一步降低了接头的性能。

通过模拟研究了不同孔隙率和相同孔隙率下不同孔径对压缩性能的影响。研究发现,随着孔隙率的增大,AFS的屈服强度和弹性模量减小,压缩过程的屈服平原阶段越明显。表明当孔隙率较大时,AFS能在较低的应力水平发生变形,吸收能量的平稳性更好。在相同孔隙率不同孔径的情况下,模拟结果显示孔径越小,弹性阶段的弹性模量越大,屈服平台阶段的平均应力更高。对搅拌头转速为1000rpm、进给速度为50mm/min的焊接参数下的焊接过程使用ANSYS进行了数值模拟,焊接过程中最高温度约为519℃,接头横截面温度场呈“V”型分布,且模拟得到的接头横截面温度场分布与实际接头横截面宏观组织分布基本一致,验证了模拟的准确性。

本实验旨在实现泡沫铝和高强钢的结合,制备出泡沫铝“三明治”结构,研究非镀锌钢-铝搅拌摩擦焊接头接头的结合方式,为提高副车架的轻量化水平提供重要的理论依据。

关键词:泡沫铝,三明治,搅拌摩擦焊,高强钢

Abstract

Aluminum Foam Sandwich (AFS) is an excellent lightweight structure with excellent performance such as light weight, high specific stiffness, high damping, energy and sound absorption, which is widely used in aerospace, aviation, automobile, ship, construction and other industries. This project using friction stir welding process is studied in the preparation of the microstructure and mechanical properties of AFS, and use ABAQUS to simulate the dynamic compression compression performance of AFS, porosity and pore diameter size was studied in AFS compression performance and the influence of using ANASY to simulate the welding process of china-africa galvanized high strength steel/aluminium DP590 friction stir welded lap joints of the change of temperature field.

It is found that the prefabricated body has a good deformation capacity at high temperature. When the heating temperature is 450℃, its elongation can reach 17.5%, and its deformability is less than 10% compared with that of aluminum foam, which provides a possibility for the preparation of parts with complex AFS structure. The sandwich structure of profiled aluminum foam was prepared by friction stir welding, and the connection between aluminum foam and steel was realized successfully. Through the observation of the steel-aluminum bonding interface, it is found that the bonding mode of non-galvanized steel-aluminum joints in the welding core area is mechanical bonding + metallurgical bonding, while there is no IMC layer at the interface outside the welding core area, and the mechanical bonding between the steel-aluminum joints is only realized through mutual embedding. Non-galvanized steel - aluminum joint IMC layer is thin, only 1~3 m, interface bonding area is small. In addition, there may be microcracks and other defects at the mechanical interface, which further reduce the performance of the joint.

The effects of different pore sizes on compression performance with different porosity and same porosity were studied by simulation. It was found that with the increase of porosity, the yield strength and elastic modulus of AFS decreased, and the yield plain stage of compression process became more obvious. It indicates that when the porosity is large, AFS can deform at a lower stress level and have better energy absorption stability. At the same porosity and different pore sizes, the simulation results show that the smaller the pore size is, the greater the elastic modulus is, and the higher the average stress is at the yield platform stage. Of stir head rotation speed is 1000 RPM, the feed speed is 50 mm/min under the welding parameters using ANSYS numerical simulation of welding process, welding process of the highest temperature is about 519 ℃, joint cross section temperature field distribution is a "V" type, and the joint simulation to get the cross section of transverse section temperature field distribution and the actual joint macroscopic organization distribution, verified the accuracy of simulation.

This experiment aims to realize the combination of aluminum foam and high-strength steel, to prepare a foamed aluminum “sandwich” structure, and to study the combination of non-galvanized steel-aluminum friction stir welded joints, which provides an important way to improve the lightweight level of the subframe. Theoretical basis.

KeyWords:Aluminum foam, sandwich, friction stir welding, high strength steel

目录

第一章绪论 1

1.1课题研究背景 1

1.1.1论文研究背景 1

1.1.2泡沫金属材料概述 2

1.1.3泡沫铝三明治板的应用 4

1.2制备泡沫铝三明治板的国内外研究现状。 5

1.2.1胶粘复合工艺 5

1.2.2焊接工艺 6

1.2.3发泡填充工艺 6

1.2.4复合预制体原位发泡工艺 7

1.3 钢-铝复合结构搅拌摩擦焊接头的国内外研究现状 8

1.4 本文的主要研究内容 9

第二章实验材料及设备 12

2.1 试验材料 12

2.1.1 制备AFS预制体的基材 12

2.1.2 发泡剂和稳定剂 12

2.2制备实验 13

2.2.1 预制体制备试验 13

2.2.2 发泡试验 15

2.3微观组织观察和性能测试 16

2.3.1 微观组织观察 16

2.3.2 力学性能测试 18

第三章泡沫铝预制体 21

3.1宏观表征 21

3.2不同温度下预制体变形能力的研究 21

3.3泡沫铝发泡原理 24

3.4 泡沫铝的发泡试验 24

第四章泡沫铝/钢“三明治”复合结构 27

4.1 泡沫铝/钢“三明治”复合结构的制备方式 27

4.2 钢-铝FSW接头宏观形貌和微观组织分析 29

4.2.1 接头宏观形貌 29

4.2.2 接头界面层形貌 30

4.2.3 接头界面IMC成分 31

五章 AFS动态压缩性能模拟和钢-铝FSW搭焊接头模拟 36

5.1泡沫铝三明治板的动态压缩模拟 36

5.1.1 动态压缩模型的建立 36

5.1.2压缩性能 37

5.1.3 AFS动态压缩过程分析 39

5. 1.4 孔隙率对AFS动态压缩性能的影响 41

5.5孔径大小对AFS动态压缩性能的影响 42

5.2 钢-铝搅拌摩擦焊搭接头的温度场模拟 43

5.2.1 热源模型的建立 44

5.2.2 钢铝FSW搭焊接头温度场模拟结果 45

结论 49

参考文献 50

致谢 50