扇形板成形工艺及模具设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

扇形板成形工艺及模具设计(含CAD零件图装配图)(任务书,开题报告,论文说明书12000字,CAD图8张)

摘要

我国的模具行业已有了一定的规模。目前,已可以较好的制造出各种形状复杂、高精度的零件。其中,锻模属于应用范围较广的一类模具。在锻模范围里,精密锻造在近年来逐渐占据了主导地位,精密锻造得到的产品形状尺寸精准、材料性能优越。通过对精密锻造的了解,可以帮助我们了解锻造行业的发展走向和研究方向。

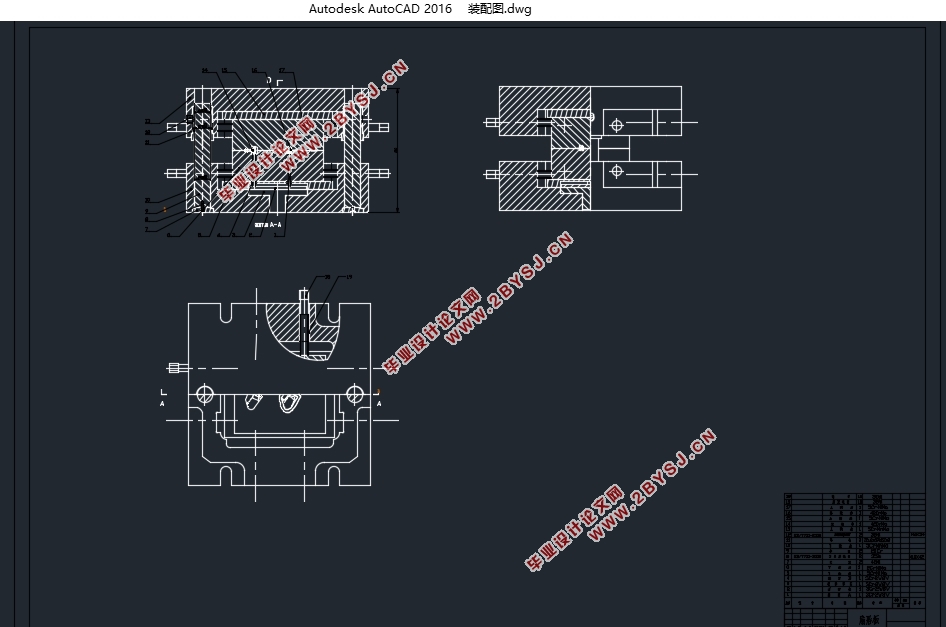

此次毕业设计的要求就是根据所给的扇形板的锻件图,完成其成形工艺、模具设计。同时用有限元分析软件对成形过程进行分析。在这一过程中,我们需要确定压力机的种类、吨位,锻件的成形工艺流程,完成零件的UG造型,设计模具的模膛、模架、顶料装置、导向装置等,用Deform模拟锻件的成形过程,根据成形得到的结果来改善预制坯工序以及相关工艺参数,确定自己模具设计和工艺流程方案。

最终,得到了制造扇形板的一套模具,并绘制了相应的CAD图纸,通过Deform成功的模拟了锻造过程,得到了形状适合、充型比较完整的锻件。验证了所设计的模具的可行性。在设计的过程中,加深了自己对UG造型、Deform模拟解、CAD绘图、锻模设计流程的认识。

关键词:精密锻造;UG;Deform;模具;

Abstract

The mold industry in our country is at quite large scale. At present, it is possible to make all kinds of complex shapes with high precision. Among them, the forging model belonging to a type of mold is widely applied. In the scope of forging die, precision forging gradually hold a dominant position in recent years, the size and shape of products forged by precision forging is precise, the material performance is superior, at the same time it can save a lot of subsequent processing. Therefore, research on precision forging is of great significance. Through the understanding of precision forging, we can understand the trend of the forging industry, can compare the advantages of precision forging. The most important thing is it can help us understand the process of precision forging, the details of how to design the forging process, and the selection of the relevant process parameters.

The requirement of this graduation design is to complete its forming process and die design according to pattern. At the same time, a finite element analysis software was used to analyze the forming process. In this process, we need to ascertain the press machine, the forging process, the UG modelling and the design of the frame of die, die chamber, lifter device, guide device, etc., to simulate the Deform forming process and to improve the blocking process in advance according to the results of the forming and related process parameters to improve the die design. Finally get the mold diagram and the process plan of the design.

Through a semester of design, with the help of the teacher, senior, classmates, I finally complete all the requirements of the graduation design. I design a set of die manufacturing for my workpiece, draw the corresponding CAD drawings. The workpiece is successfully simulated by Deform, the shape, size, smooth of its surface of forgings is perfect. At the same time, in the process of design, I get a deeper understanding of the UG modelling, Deform simulation, application of CAD and the process of forging die design.

Key words: precision forging; UG; Deform; die

目录

摘要 I

Abstract II

第一章绪论 1

1.1 模具行业的发展和锻模的发展 1

1.2 锻模的分类 1

1.3 精密模锻的分类和选择 1

1.4 精密模锻的前景 2

1.5 课题的内容及意义 2

第二章成形工艺分析 3

2.1 压力机的选择 3

2.2 锻造方法的选择 3

2.3 锻造温度的选择 3

2.4 工艺流程方案 3

2.5 模具结构、型腔布局 4

2.6 本章小结 4

第三章 UG造型与工艺计算 5

3.1 UG的基本介绍 5

3.2 终锻件的造型 5

3.3毛坯的计算 10

3.4 飞边的造型 11

3.5 预锻件造型 12

3.6 本章小结 13

第四章模具设计 14

4.1 锻模的设计程序和一般需求 14

4.2 螺旋压力机上模锻件分类 14

4.3 模膛与模块设计 15

4.4 模块的确定 16

4.5 飞边槽结构形式及尺寸确定 20

4.6 模架设计 20

4.6.1 导向装置设计 21

4.6.2 顶料装置的设定 23

4.6.3 固定方式的选择 24

4.6.4 保护装置 26

4.7 装配 26

4.8 预制坯模设计 27

4.9 模具CAD图 28

4.10 本章小结 28

第五章 Deform模拟 29

5.1 预锻模拟 29

5.2 终锻模拟 30

5.3 本章小结 31

结论与展望 32

致谢 33

参考文献 34