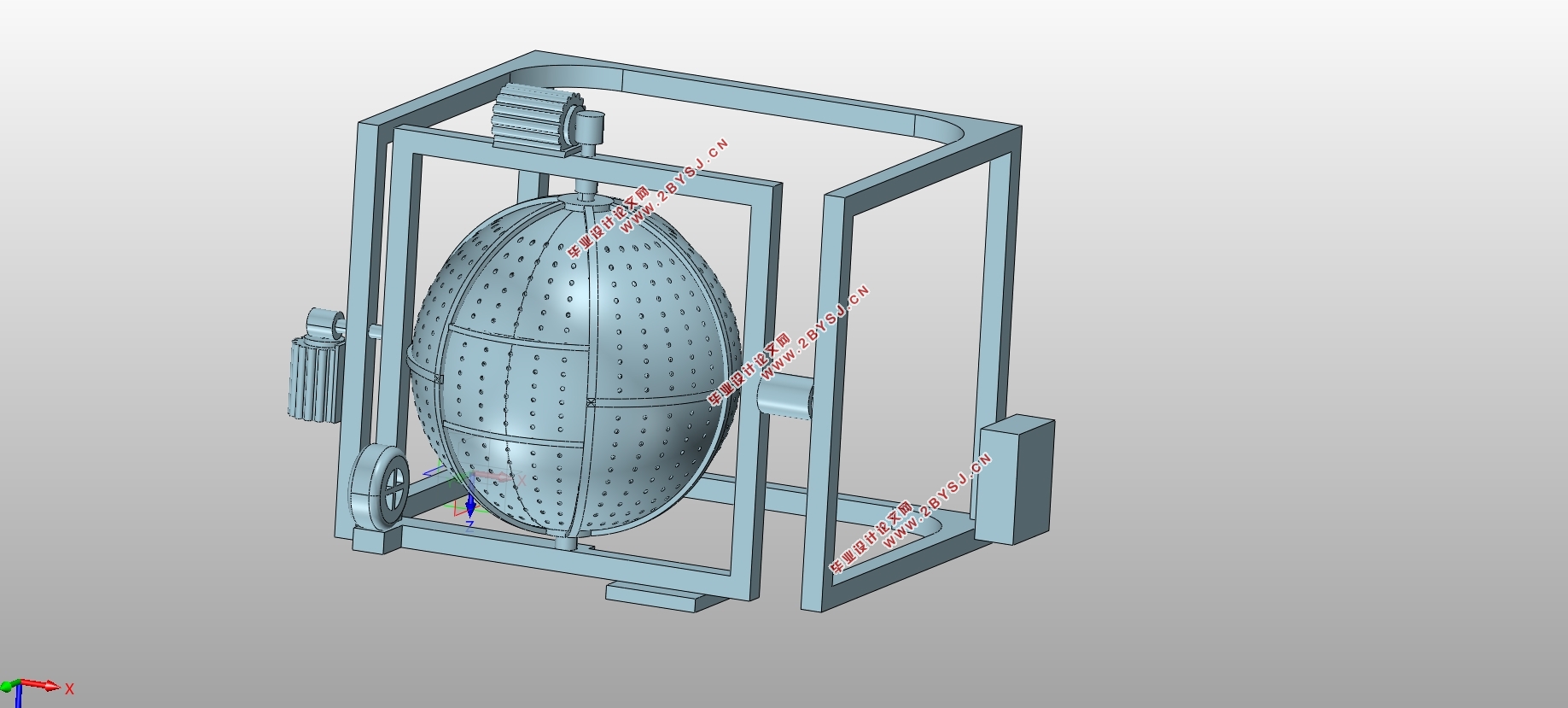

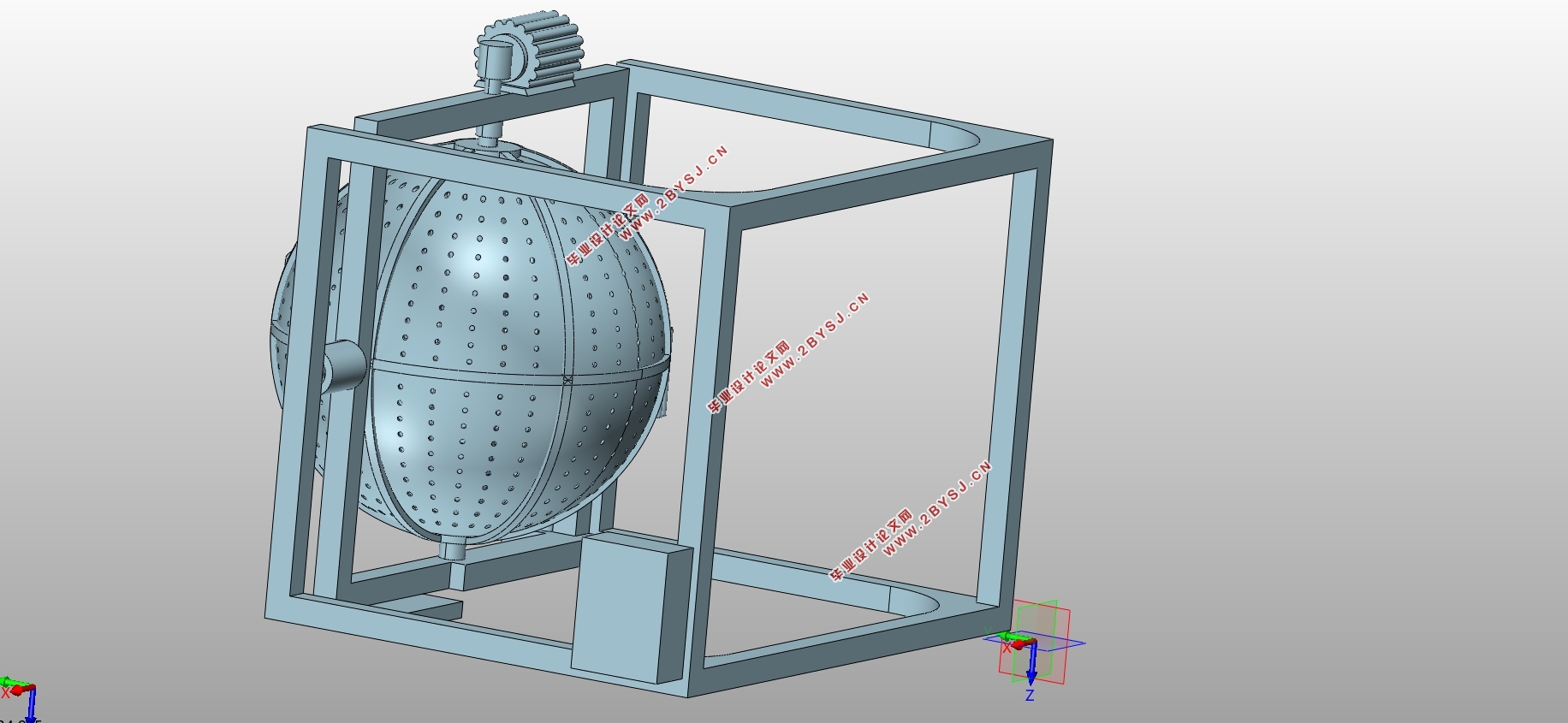

武夷岩茶摇青匀堆一体机设计(含CAD图,PROE三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

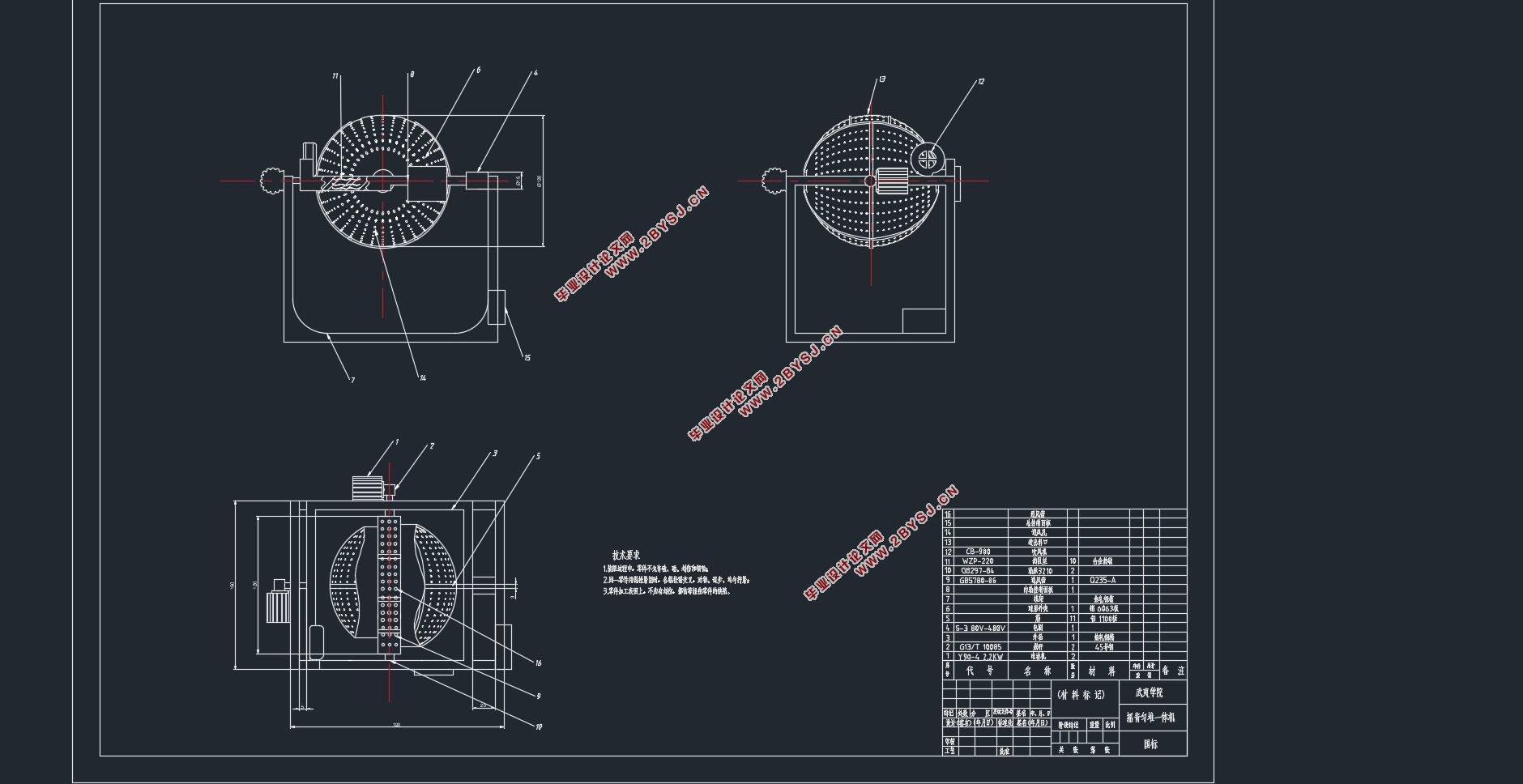

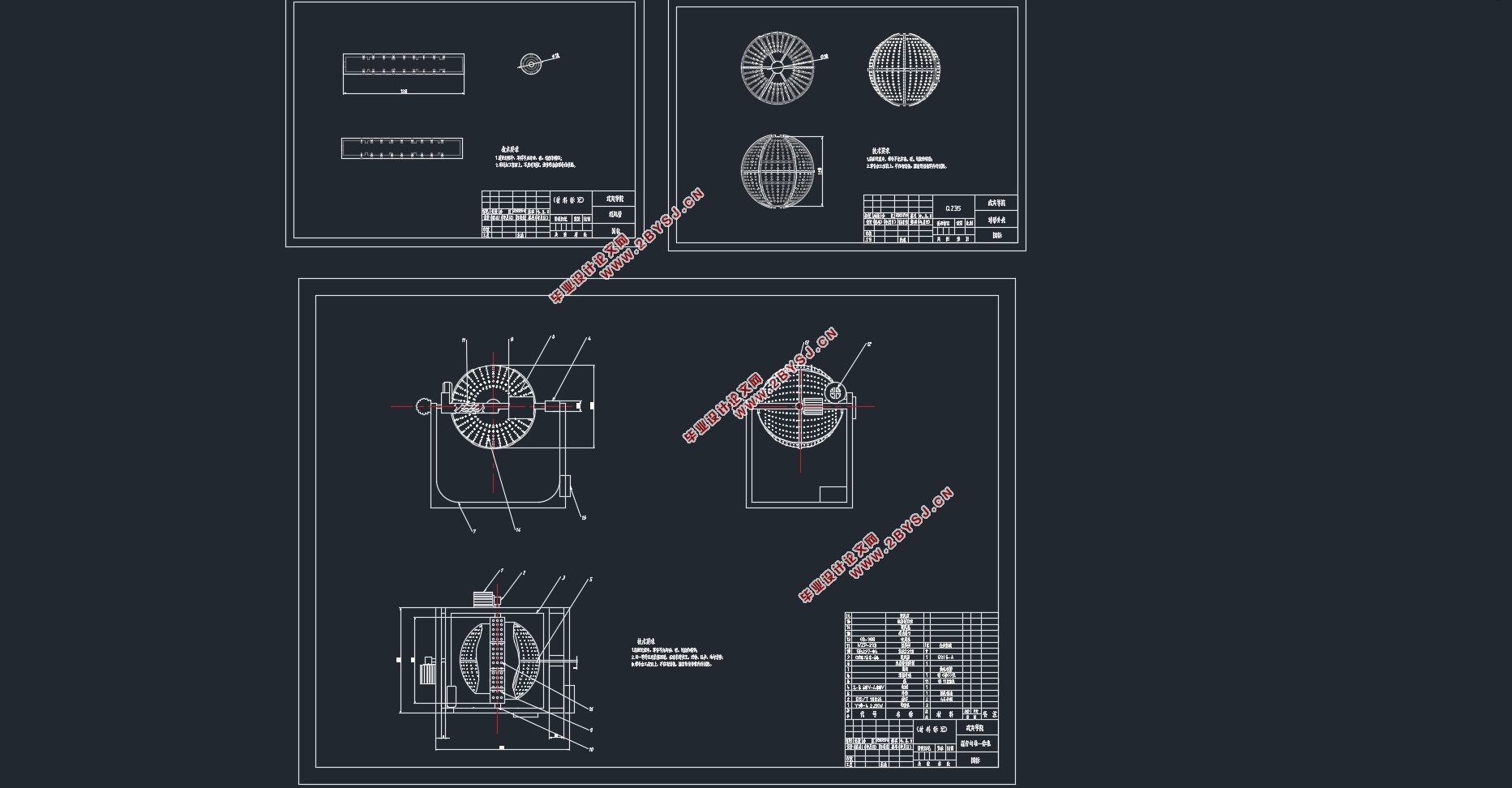

武夷岩茶摇青匀堆一体机设计(含CAD图,PROE三维图)(任务书,文献综述,开题报告,中期检查表,论文说明书10000字,CAD图3张,PROE三维图,答辩PPT)

摘要

该毕业设计设计针对目前市场上摇青机、匀堆机的缺点,设计了双轴,球罐式茶叶摇青匀堆一体机。总体方案与结构选取市场上6CWY-90型摇青机作为结构设计和优化的对象,将摇青机、匀堆机有效的结合在一起,并对其结构尺寸进行了计算,优化了其传动系统、风管等零部件。最后利用有限元进行了风管和球罐的温度场分析。其中主要动力由两个电机提供,通过蜗杆和轴承、电刷、通风管、机架、球罐和控制面板共同组成。针对传统摇青机以及匀堆机的温度不均匀,主要对摇青匀堆一体机风管、外形结构上进行改进,利用Pro/E对风管和外形结构进行三维建模,用有限元分析进行模型分析,选出最优化的风管结构。

关键词:茶叶摇青、茶叶匀堆、一体机设计、有限元分析

Abstract

In view of the shortcomings of shaking machine and stacker in the market, the graduation design has designed a two-axis, spherical pot tea shaking machine and stacker. The overall scheme and structure select 6CWY-90 type shaker in the market as the object of structural design and optimization. The shaker and stacker are effectively combined, and their structural dimensions are calculated, and their transmission system, air duct and other components are optimized. Finally, the temperature field of air duct and spherical tank is analyzed by finite element method. The main power is provided by two motors, which are composed of turbine worm and bearing, brush, ventilation pipe, frame, spherical tank and control panel. Aiming at the uneven temperature of traditional shaker and stacker, this paper mainly improves the air duct and shape structure of shaker and stacker. Pro/E is used to build the three-dimensional model of air duct and shape structure, and finite element analysis is used to analyze the model, and the optimized air duct structure is selected.

Keywords:Green tea leaves;Tea heap;Integrative Computer Design;finite element analysis.

目 录

1 引言 1

1.1摇青匀堆一体机的研究背景与意义 1

1.2国内外研究现状及发展趋势 2

1.3 课题研究内容 3

2 摇青匀堆一体机的方案选择与总体结构 5

2.1摇青的方式 5

2.1.1 摇青方式的确定 5

2.2匀堆的方式 6

2.2.1匀堆方案的确定 7

2.3 摇青匀堆一体机总体方案确定 7

2.4 摇青匀堆一体机总体结构 7

3 传动方案设计 9

3.1传动方案与电机选择 9

3.1.1传动总体方案设计 9

3.1.2电机的选择 10

3.1.3确定总传动比和分配传动比 11

3.2电刷的选择 12

4 摇青匀堆一体机零部件设计 14

4.1外形尺寸 14

4.2 风筒冲孔尺寸的确定 15

5 摇青匀堆一体机吹风管结构优化 17

5.1 摇青匀堆一体机吹风管结构改进 17

5.1.1 吹风管改进的方案 17

5.1.2有限元分析 19

5.1.3 吹风管改进方案的选取 20

5.2摇青匀堆一体机球罐内部温度场分析 20

5.2.1 有限元分析 21

6 结论 27

谢辞 28

参考文献 29