多头锁螺丝机的设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

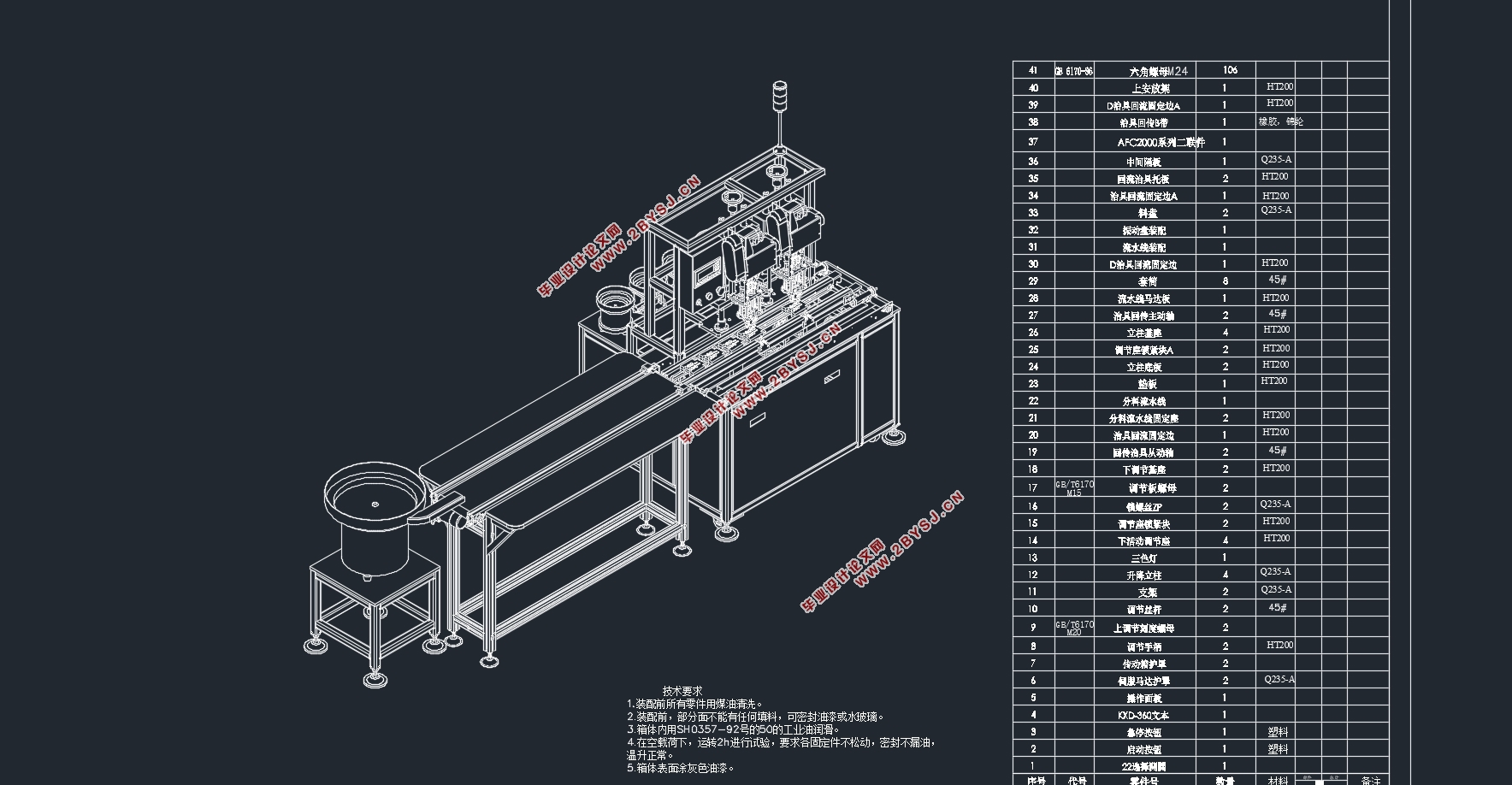

多头锁螺丝机的设计(含CAD零件图装配图)(选题审核表,任务书,开题报告,外文翻译,论文说明书15000字,CAD图6张)

Multi-head lock screw machine

摘要

目前,中国固定螺丝机的发展才刚刚开始。国内的市场需求较大。随着中国工业力量的不断扩大,对工业技术方面的资金投入量的增加,涌入了大量的专业技术人才,加速了中国工业技术改革。通过不断发展,如今自动紧固螺丝机的类型也有许多种,如多轴自动紧固类螺丝机,旋转自动型,多头自动型,手持式自动型,落地式自动型等。一开始,我国的绝大部分自动螺丝机都是从国外进口的,如美国,德国等。我国机械行业不断地在进步,螺丝机等机械类产品也顺势而起,而且前景十分广阔,相关企业也在全面发展技术优化,成本改良。现如今,我国定制装备工业等领域发展极为优先,具体在珠江三角洲、上海、广东等大中城市郊区为主要生产基地。 最近这些年,我国引进了自动锁紧螺丝,各个公司对其对其抱有很大的期待。在这些螺丝机类型中,便携式自动螺丝机更受市场的欢迎,它在加工领域比较方便,价格也是比较便宜的,而一些低端和廉价的自动锁紧螺钉机生产占有大量的小型和微型制造市场,目前高端自动锁紧螺钉机的生产水平较低。

本文设计是一种冶金工具用多头锁紧螺丝机,属于机械加工设备技术领域。 本实用新型包括冶金工具进给装置、冶金工具传动装置、多头锁紧螺钉装置、冶金工具回流装置和冶金工具进给装置,其包括: 冶金工具进给架和冶金工具振动进给机,冶金设备传动装置的传动帘设置在第一传动辊和循环中的第二传动辊上。多头锁紧螺钉装置包括锁紧螺钉架、锁紧螺钉机构和螺钉进料机构、冶金设备支承循环机构。本文中设计的多头锁紧螺钉机有很多的优点,它的稳定性高、效率高、自动化程度高、智能化程度高的优点和特点,而且具有良好的通用性和广泛的应用前景。

关键词:多头 ;锁紧螺丝机 ;自动化

Abstract

At present, the development of screw engine in China is still in its infancy. Now our country's screw machine demand is still very big. With the development of industry, the technical level of screw machinery is constantly improving, and the products are becoming more and more diversified.There are already multi-head automatic locking screw machines, multi-axis automatic locking screw machines, rotary automatic screw machines, and hand-held automatic locking screw machines, floor-type automatic lock screw machine and other automatic lock screw machine. First of all, most of our automatic closing machines from Japan, Germany, the United Kingdom and other developed countries Imported. Many Last year our personalized equipment industry has developed rapidly, mainly in the Pearl River Delta and Yangtze River Delta Economies. The the main production areas and industrial bases are located in the suburbs of the large and medium-sized cities of Shanghai and Guangdong. It There are others. In recent years, automatic locking screw machines have entered the Chinese market, the Enterprise shows high enthusiasm to the automatic lock screw machine, especially gets the favor of the large-scale manufacture enterprise. But at present, the output of our country's automatic locking screw machine is not high, and the hand-held automatic screw machine, with its price advantage and flexible output, accounts for about half of the domestic market, and some low-end and cheap automatic locking screw machine production occupies a large number of small and micro-manufacturing market, the current high-end automatic locking screw machine production is low.

The utility model relates to a multi-head lock screw machine for a metallurgical tool, which belongs to the technical field of mechanical processing equipment. The utility model comprises a feed device for a metallurgical tool, a transmission device for a metallurgical tool, a multi-head lock screw device, a reflux device for a metallurgical tool, and a feed device for a metallurgical tool, which comprises a feed frame for a metallurgical tool and a vibrating feed machine for a metallurgical tool, the transmission curtain of the transmission device for the metallurgical apparatus is arranged on the first transmission roller and the second transmission roller in a circle. The multi-head locking screw device comprises a locking screw rack, a supporting and circulating mechanism for the Metallurgical Apparatus, a locking screw mechanism and a screw feeding mechanism, the reflux device of the metallurgical apparatus comprises a shunt mechanism, a first reflux mechanism and a second reflux mechanism. The Design of this paper has non seulement High Stability, efficient, High Automation, intelligent and other features, but also has good Common and large application prospects.

Keywords:Long head;Screw locking machine; mechanical design

1.4.2 主要技术参数

1.锁螺丝机基于治具模型设计,治具信息详见任务书后附件。

2.被锁螺旋长度<30mm,2-5秒/PCS。

3. 工作电压220V,频率50Hz,功率小于1000W。

4.适用领域自动锁螺丝机应用于大小家电、玩具、等产品上螺丝锁副。

目录

摘要......................................................Ⅰ

Abstract..................................................Ⅱ

第一章 绪论..............................................1

1.2 国内外发展现状....................................1

1.2.1 锁紧螺丝机的市场前景.........................2

1.2.2 国外发展现状.................................3

1.2.3 国内发展现状.................................4

1.3 课题来源..........................................6

1.4 课题的主要要求....................................7

1.4.1 设计的主要内容...............................7

1.4.2 主要技术参数.................................7

1.4.3 设计要求.....................................7

1.5 总体方案和技术路线................................8

1.5.1 总体方案设计.................................8

1.5.2 技术路线.....................................11

第二章 传动装置的总体设计.................................12

2.1 传动方案设计.....................................12

2.2 电动机的选择设计.................................12

2.2.1 电动机的选择类型.............................12

2.2.2 确定传动装置效率.............................12

2.2.3 选择电机的型号...............................13

2.2.4 计算传动装置的运动和动力参数.................14

第三章 丝杠传动的设计

3.1 滚珠丝杠与滑动丝杠对比...........................15

3.2 丝杠传动的设计...................................15

3.2.1 滚珠丝杆的工作原理及结构形式.................15

3.2.2 丝杠副的选用及计算...........................16

3.3 螺母的设计.......................................24

3.3.1 选取螺母材料.................................24

3.3.2 确定螺母的高度...............................25

3.3.3 确定螺文工作圈数.............................25

3.3.4 螺母的实际高度...............................25

3.3.5 螺母螺纹牙的强度计算.........................25

3.3.6 螺母的强度计算...............................26

第四章 滚动轴承的选择和设计.............................28

4.1 蜗杆轴承的选择设计...............................28

4.2 蜗杆轴承的校核...................................28

第五章 项目管理和经济分析................................31

5.1 项目管理内容.....................................31

5.1.1 外购清单......................................31

5.2 结构安装说明.....................................32

5.3 调试及验收管理...................................33

5.4 功能消耗、环境分析...............................33

5.5 本设计的成本核算..................................34

总 结...................................................35

致 谢...................................................36

参考文献..................................................37