汽车废旧钢板(<3mm)锤式破碎机设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

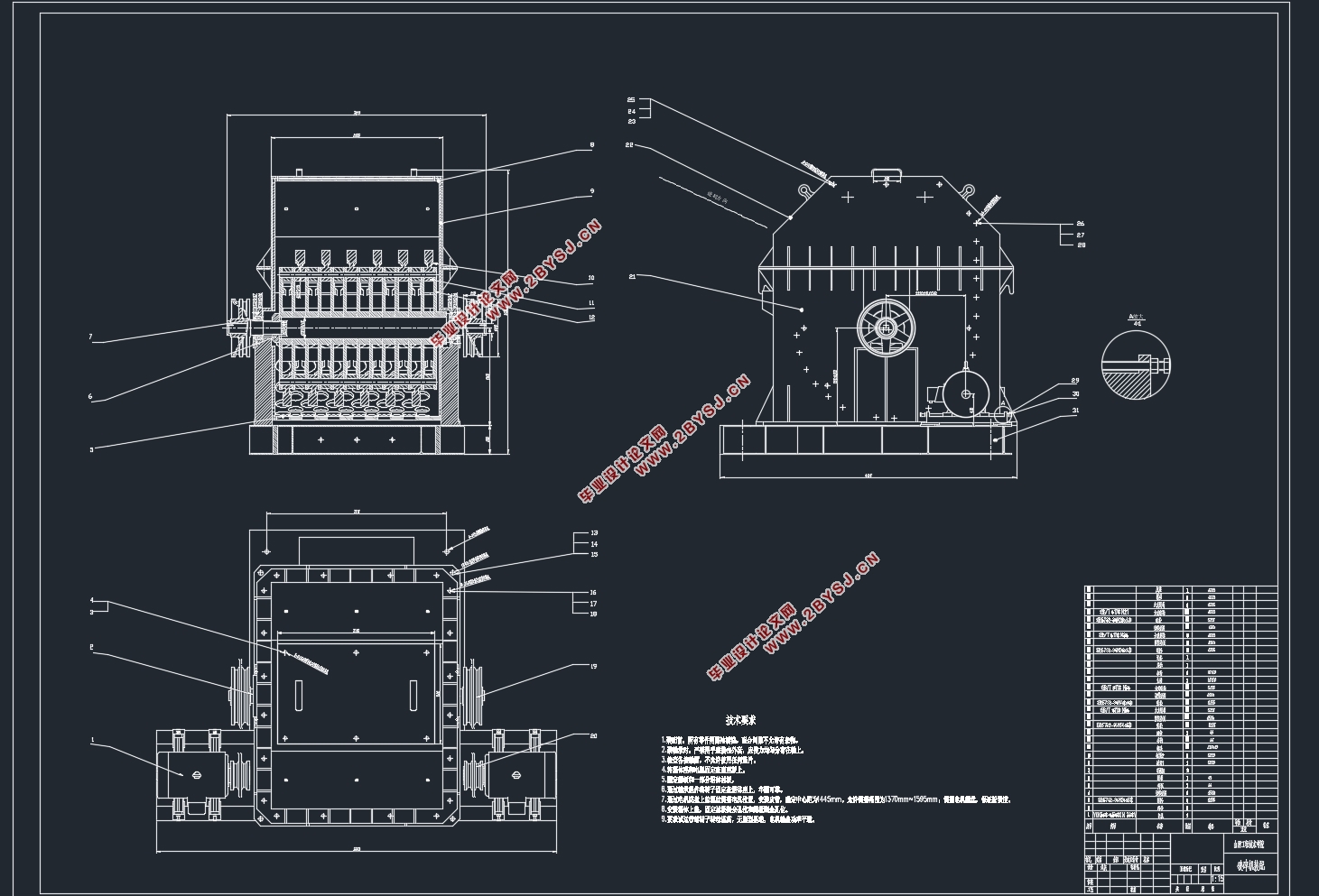

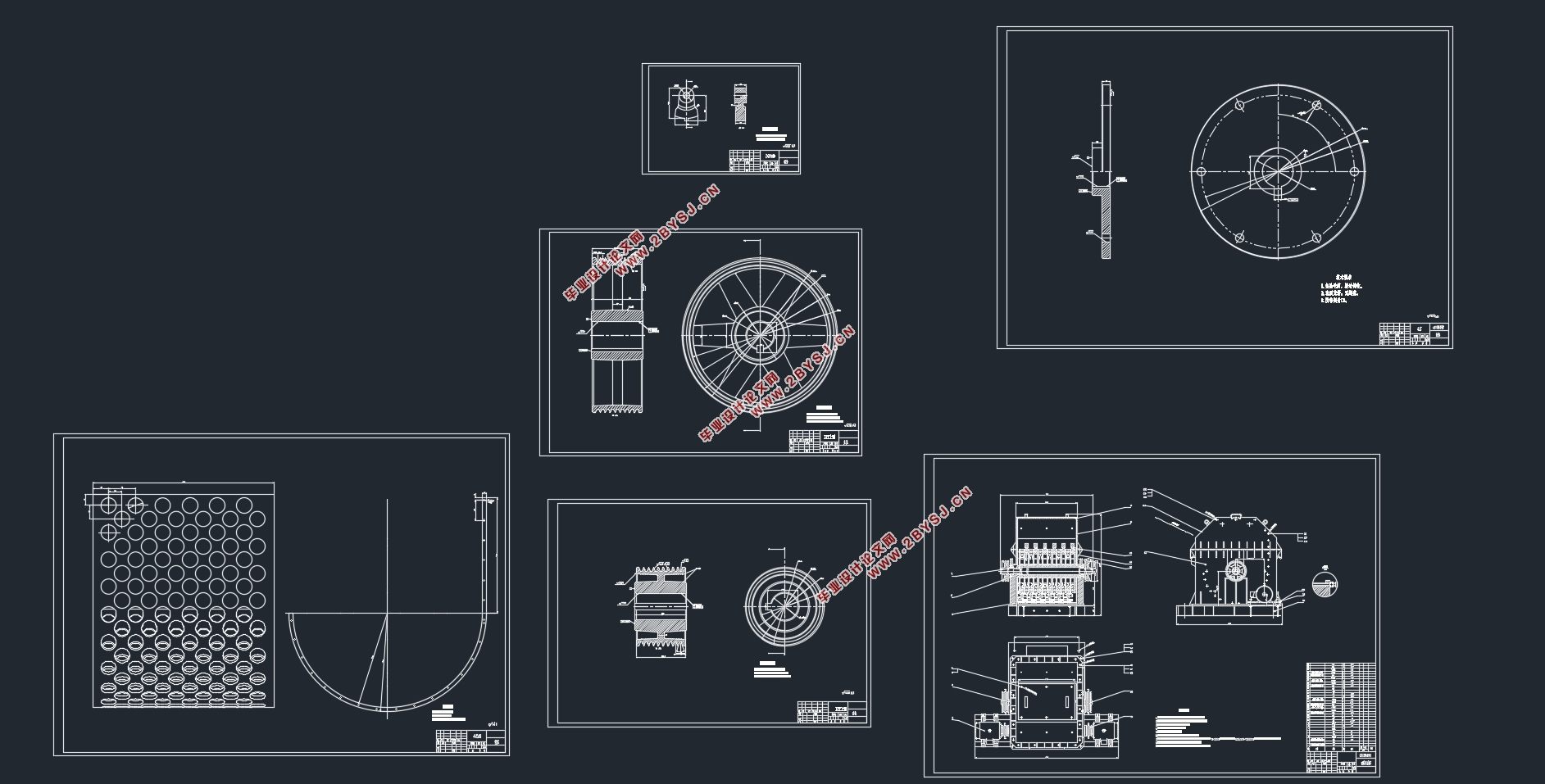

汽车废旧钢板(<3mm)锤式破碎机设计(含CAD零件图装配图)(论文说明书24000字,外文翻译,CAD图6张)

摘 要

废钢破碎机可以将各种汽车驾驶室、小型轻薄压块、摩托车架子自行车架子、电冰箱铁皮、电视机铁皮、洗衣机铁皮、易拉罐、油漆桶、油桶、彩钢瓦、烟筒皮、等壁厚在8mm以下各种废钢破碎。废钢破碎加工即利用破碎机对废旧钢板进行破碎,利用分选系统对破碎后的废钢进行分选来得到纯净的优质废钢的加工方法。其工作原理就是进料机把废铁自动运转到破碎机腔内,在高速、大扭矩电机的连续驱动下,破碎机转子上的锤头和刀片轮流击打进入容腔内的废钢。在强大的冲击力作用下,废钢被撕裂和挤压成一定规格的破碎钢,再经分选设备处理,就可得到纯度较高的优质破碎钢。

随着国民经济不断发展,人们的生活水平和消费水平逐渐提高本,从往年我国的汽车销量来看,势必带来很多报废汽车垃圾,对报废汽车钢板的处理是一个亟待解决的问题。课题旨在设计汽车废钢锤式破碎机的锤头及其传动系统的机械结构,并进行强度校核;另外,进行传动系统关键元件选择与参数匹配设计。

关键词:废旧钢板;破碎机;锤头;转子

Design of Hammer Crusher for Automobile Waste Steel Plate (<3mm)

Abstract

Scrap crusher can crush all kinds of scrap steel with wall thickness below 8mm, such as automobile cab, small light and thin press, motorcycle rack, bicycle rack, refrigerator iron, TV iron, washing machine iron, pull-out tank, paint barrel, oil barrel, color steel tile, chimney skin, etc. The crushing process of scrap steel is to use crusher to crush scrap steel, and the separation system is used to separate the crushed scrap steel to obtain pure and high quality scrap steel processing method. Its working principle is that the scrap iron is automatically run into the crusher chamber by the feeder. Under the continuous drive of high speed and large torque motor, the hammer head and blade on the crusher rotor strike the scrap steel into the chamber in turn. Under the strong impact force, scrap steel is torn and extruded into a certain size of crushed steel, and then treated by sorting equipment, high purity crushed steel can be obtained.

With the continuous development of the national economy, people's living standards and consumption levels are gradually improving. From the past year's automobile sales in China, it is bound to bring a lot of scrap automobile garbage, and the disposal of scrap automobile steel plate is an urgent problem to be solved. The purpose of this project is to design the mechanical structure of the hammer head and its transmission system of the automobile scrap steel hammer crusher, and to check the strength of the hammer head; in addition, to select the key components of the transmission system and design the parameters matching.

Key words:Scrap steel plate;Hammer crusher; Hammer head; Rotor

目 录

摘 要 i

Abstract ii

目 录 1

1 绪论 1

1.1 我国废钢铁资源现状 1

1.2 报废汽车的回收 1

1.3 轻薄型金属破碎理论 4

2 金属破碎机的分类及工作原理 5

2.1 金属破碎机的分类 5

2.1.1 易拉罐破碎机 5

2.1.2 油漆桶破碎机 5

2.1.3 汽车破碎机 5

2.1.4 废钢破碎机 5

2.1.5 废铁破碎机 6

2.2 根据破碎原理可分为两种类型 6

2.2.1 刀盘切割 6

2.2.2 摆锤撞击 6

2.3 废钢破碎机 6

2.4 废钢破碎机的发展前景 7

3 计算机辅助设计(CAD) 9

3.1 计算机辅助设计( CAD ) 9

3.2 AutoCAD2007工程制图软件 10

4 选题背景 11

4.1 课题来源 11

4.2 课题研究意义 11

4.3 主要解决问题 11

4.4 设计思路 12

5 对破碎机的理解 13

6 破碎机结构设计 15

6.1 转子主轴设计及功率计算 15

6.2 电机功率计算 16

6.3 带传动的设计 17

6.4 转子结构设计及强度校核 25

6.4.1 主轴强度校核 26

6.4.2 锤轴、锤盘、锤头的设计和校核 28

6.4.3 转子直径的校核 33

6.4.4 转子结构的校核 33

6.4.5 轴承的选择 35

6.5 筛板及箱体结构设计 39

6.5.1 筛板结构设计 39

6.5.2 箱体结构设计 40

结 论 41

参考文献 42

外文文献 43

中文翻译 49

致 谢 53