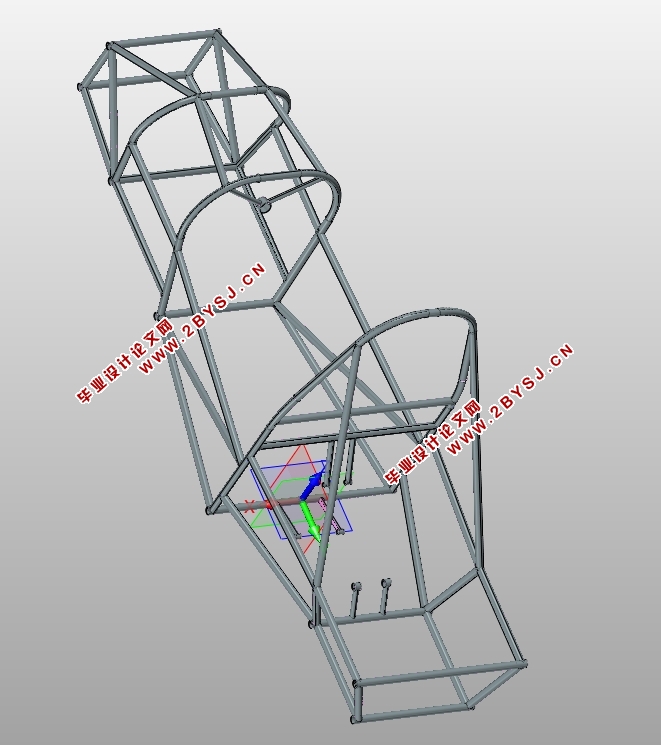

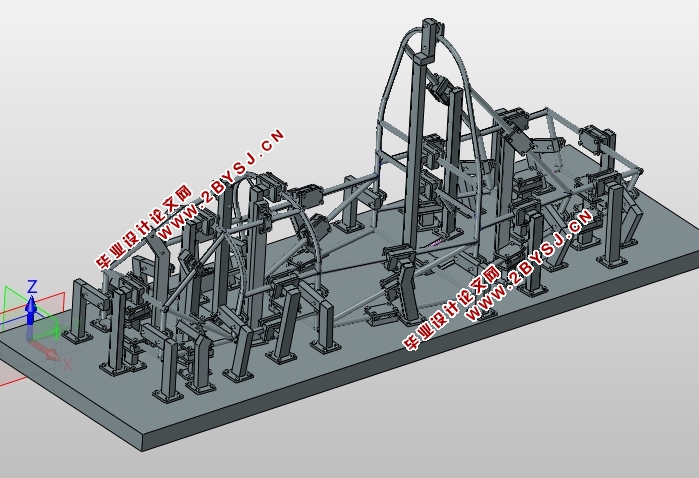

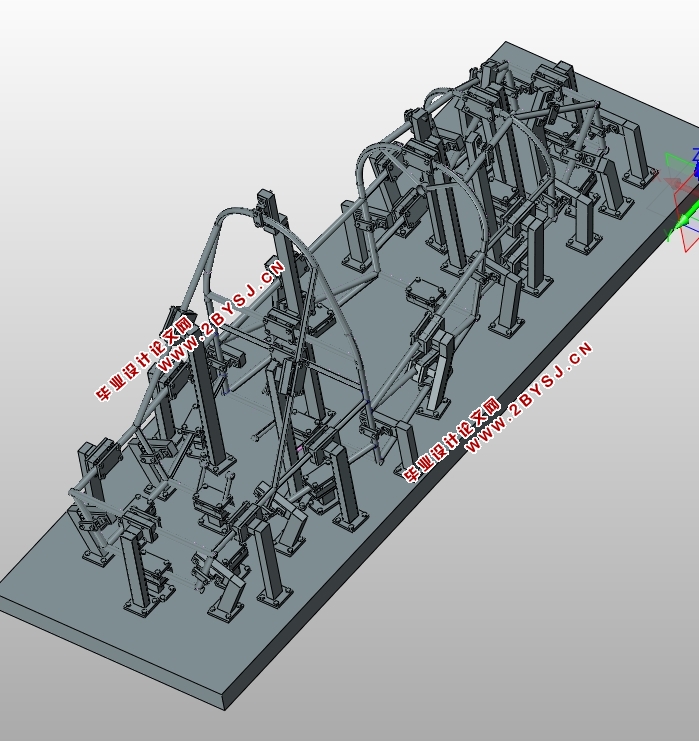

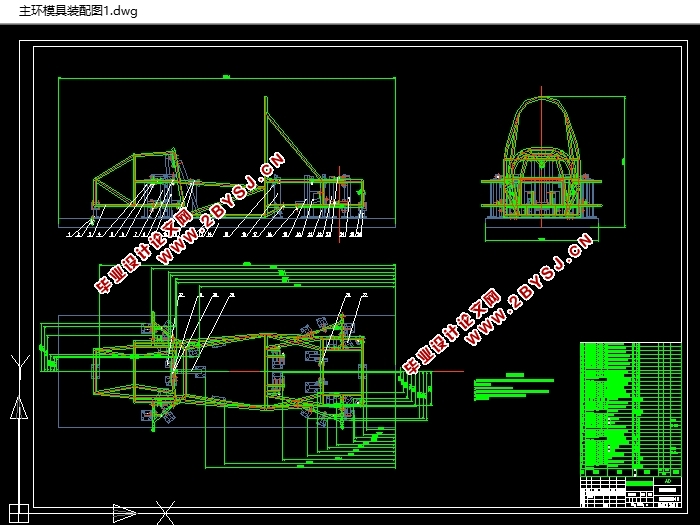

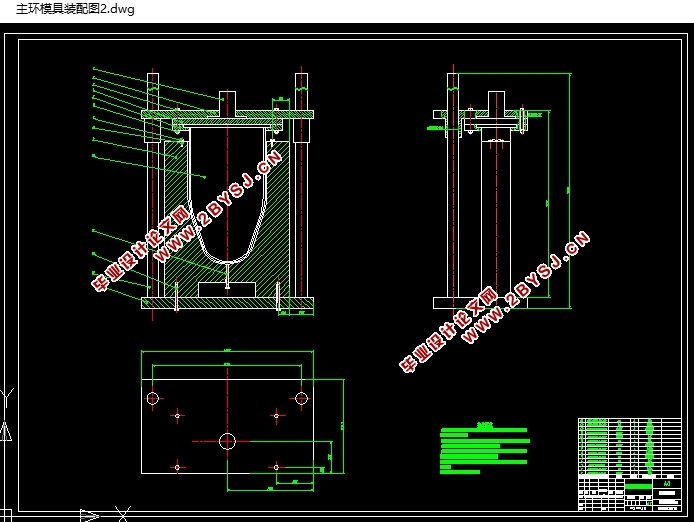

方程式赛车模具及卡具设计(含CAD装配图,UG三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

方程式赛车模具及卡具设计(含CAD装配图,UG三维图)(开题报告,外文翻译,论文说明书20000字,CAD图纸3张,UG三维图)

摘 要

本文依据大学生方程式汽车大赛FSAE赛事技术规则对大学生方程式赛车整体车架、悬架进行了模具及卡具设计。在卡具设计当中不仅需要考虑赛车车架各杆件是否定位完全以及夹紧可靠,同时必须考虑支撑杆件的强度和刚度能否满足要求,最终还必须考虑焊接空间是否与支撑杆干涉。在模具设计当中不仅要考虑凸、凹模的加工精度以及冲压机的选择,同时还必须考虑凸、凹模的强度和刚度。本文在完全满足上述要求的前提下对模具及卡具进行了设计。

在模具及卡具设计之初,将方程式汽车大赛的有关规定和评分标准,作为后续模具及卡具设计的技术规范要求;为了达到卡具设计合理性的目的,本设计参考了湖南大学、天津大学以及部分国外大学的赛车模具及卡具。进入设计阶段,本设计通过分析比较几种模具及卡具的结构形式,决定选择定位与夹紧一体化的卡具设计,采用压弯模制得对强度要求较高的主环。然后依据技术规范、车架的最终尺寸确定了卡具及模具的结构形式和具体尺寸,并在UG7.0中建立车架卡具的模型。再对模具及卡具进行受力分析,使各杆件能合理的定位、夹紧,使主环能满足强度和精度的要求,直至模具及卡具结构满足各个方面的要求。

关键词:FSAE,模具,卡具,建模,工艺分析

FORMULE SAE—A MOLD AND FIXTURE DESIGN

ABSTRACT

Based on equation FSAE car competition event technical regulations of university students for the college students formula overall frame, suspension for the mould and fixture design. In fixture design not only need to consider whether or not the car frame each bar of positioning and clamping completely reliable, at the same time must consider the strength of the support bar and stiffness can meet the requirements, the final must also consider whether the welding space interference with the support bar. During mold design should not only consider the machining precision of the convex, concave die and punch, also must consider the intensity of the convex, concave die and stiffness. In this paper, on the premise of fully meet the above requirements on the mould and fixture design.

At the beginning of the mould and fixture design, the formula car contest regulations and criteria, as the follow-up mold and fixture design of the technical specification requirements; In order to achieve the purpose of fixture design rationality, the design reference of Hunan university, Tianjin university and some of the foreign car mold and fixture. Entered the stage of design, this design through the comparative analysis several kinds of mould and the structure of fixture, decided to choose integration of positioning and clamping fixture design, USES the bending molding of strength to demand higher main ring. Then according to specification, to obtain the final size of the frame the structure of the mould and fixture and the specific size, and set up in the UG7.0 frame models of the fixture. Stress analysis was carried out on the mold and fixture, make each bar can reasonable positioning, clamping, the main ring can meet the accuracy requirement of the strength and, until the mold and fixture structure meet the requirements of all aspects.

Key words: FSAE, mould, fixture, modeling, process analysis

目 录

第一章 绪 论 1

§1.1 赛事简介 1

§1.2 大赛性质 2

§1.3 大赛理念 2

§1.4 愿景与使命 2

§1.5 组织结构 3

第二章 焊接卡具的设计 4

§2.1 焊接的主要类型 4

§2.1.1 点焊 4

§2.1.2 凸焊 4

§2.1.3 钎焊 5

§2.1.4 二氧化碳焊 5

§2.2 车用焊接卡具分析 5

§2.3 焊接夹具的分类 6

§2.3.1 无驱动夹具 6

§2.3.2 气动夹具和手动夹具 6

§2.4 焊接夹具的结构设计 7

§2.5 六点定位原则在车身焊装夹具上的应用 7

§2.6 焊装夹具设计原则 8

§2.7 焊装夹具的基本要求 8

§2.8 工艺分析 9

§2.8.1 车架的分析 9

§2.8.2 基准的选择 9

§2.8.3 制定工艺路线 10

§2.9 定位、夹紧元件的选择 11

§2.9.1 定位元件及定位方式的选择 11

§2.9.2 工件的夹紧及对夹紧装置的要求 13

§2.9.3 定位误差的分析与计算 13

§2.10 工件的夹紧 14

§2.10.1 夹紧装置的设计原则 15

§2.10.2 夹紧力确定的基本原则 16

§2.10.3 减小夹紧变形的措施 18

第三章 模具的设计 20

§3.1 模具的发展与现状 20

§3.1.1 国内模具的发展与现状 20

§3.1.2 模具CAD/CAE/CAM技术 22

§3.2 零件工艺性分析 23

§3.2.1 材料选择 23

§3.2.2 结构分析 23

§3.2.3 工艺分析 24

§3.3 U形件弯曲模结构设计 25

§3.3.1 模具的整体结构 25

§3.3.2 凸、凹模的结构和固定形式 25

§3.4 模具零件的设计与计算 26

§3.4.1 凸、凹模的间隙 26

§3.4.2 弯曲力计算 27

§3.4.3 凸模长度的确定 28

§3.4.4 凹模尺寸的确定 28

§3.5 冲压设备的选用 29

§3.5.1 冲压设备主要技术参数 29

§3.5.2 冲压力的计算 31

§3.5.3 选择压力机 31

§3.6 模具强度和刚度的计算 32

第四章 结 论 35

参考文献 36

致 谢 38