刮板输送机的设计(含CAD零件图装配图)☆

无需注册登录,支付后按照提示操作即可获取该资料.

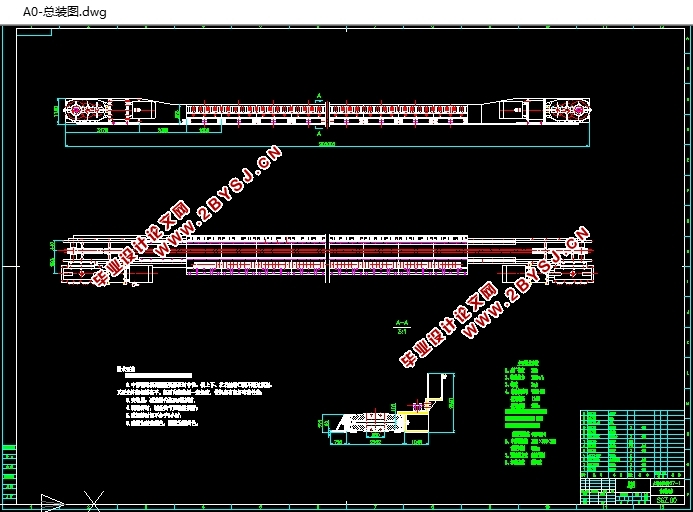

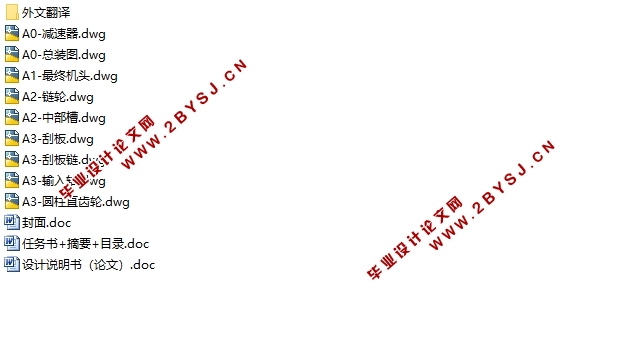

刮板输送机的设计(含CAD零件图装配图)☆(任务书,外文翻译,论文说明书26000字,CAD图纸9张)

摘 要

刮板输送机是一种挠性牵引的连续输送机械,是为了采煤工作面和采区巷道运煤布置的机械。它的牵引构件是刮板链,承载装置是中部槽,刮板链安置在中部槽的槽面。中部槽沿运输线路全线铺设,刮板链绕经机头,机尾的链轮接成封闭形置于中部槽中,与滚筒采煤机和输送机推移装置配套,实现落煤、装煤、运煤以及推移输送机械化。沿输送机全长都可向溜槽中装煤,装入中部槽中的煤被刮板链拖拉,在中部槽内滑行到卸载端卸下。

用刮板输送机运送散碎物料的方式20世纪初出现于工业发达的英国。早期的刮板输送机结构简单轻便,仅用作运煤,需人工装煤,运输能力低,每小时最多只能运几十吨;输送机长度只有几十米;功率小,牵引链的强度也不高。经过多年的改进和发展,目前综采矿用的刮板输送机除了运煤之外,还有四种功能:给采煤机作运行轨道;为拉移液压支架作伸缩油缸的固定点;清理工作面的浮煤;悬挂电缆、水管、乳化液管等。

本说明书主要介绍了输送机传动部的设计计算。SGZ764/320型输送机传动部主要是由一个电动机、减速箱和液力偶合器组成,该输送机内横向布置,电动机输出的动力经由三级传动的圆锥圆柱齿轮减速速器传动。在设计过程中,对传动部的轴、传动齿轮、轴承和联接用的花键等部件进行了设计计算、强度校核和选用。本说明书主要针对主要部件的设计计算和强度校核进行了叙述和介绍。

关键词:连续运输; 刮板链; 减速器; 设计

Abstract

Conveyor is a flexible mechanical traction of the continuous conveyor is to coal face and the coal mining area of roadway layout of machinery. It is a scraper chain traction component, carrying equipment in the central trough, scraper chain placed in the middle slot of the groove surface. Central groove along the transportation routes across the board laying around by the nose scraper chain, sprocket tail then placed into a closed-shaped central slot, with the passage of Shearer and conveyor equipment necessary, to achieve loading of coal, coal loading, coal and transport mechanization over. Along the full can to the chute conveyor are installed with coal, the coal is loaded into the central tank scraper chain drag, slide in the central tank to remove the uninstall side.

Chain conveyor means transporting scattered and fragmentary material appeared in the early 20th century industrial development in the United Kingdom. Early conveyor simple light, just as coal, manual loading of coal required, transport capacity, and can only transport hundreds of tons per hour; conveyor length of a few dozen meters; power is small, the intensity of traction chain not high. After years of improvement and development of mechanized mining, the current conveyor used in addition to coal, there are four functions: to Shearer for orbit; to Pull for telescopic hydraulic cylinder of the fixed point; clean up float coal face; suspension cables, water pipes, emulsion tubes.

This manual introduces the conveyor drive on the design calculations. SGZ764/320 types Conveyor Drive Division is by a motor, reduction gearbox and fluid coupling formed within the horizontal layout of the conveyor, the motor output of the power transmission through three cone cylindrical gear speed Transmission. In the design process, the Department of the drive shaft, transmission gears, bearings and spline connection with the design calculations and other components, strength check, and use. The main components of this manual aimed at the design and strength check calculation was described and introduced.

Key words: continuous transportation; scraper chain; reducer; design

设计参数:

设计长度: 200 m

输送能力: 1000 t/h

刮板链速: 2 m/s

总装机功率:2×250 kW

目 录

1 概述 1

1.1刮板输送机的机构与作用 1

1.2刮板输送机的工作原理 1

1.3输送机的发展概况 1

1.4国内外刮板输送机的技术特点及趋势 1

1.4.1先进产煤国家刮板输送机的技术发展 1

1.4.2我国刮板输送机的技术改进方向 2

2 主要部件的结构和设计要求 3

2.1机头部 4

2.1.1机头架 4

2.1.2链轮 5

2.1.3减速器 5

2.1.4盲轴 6

2.1.5联轴器 6

2.1.6电动机 7

2.2 机尾部 7

2.3中部槽及附属部件 8

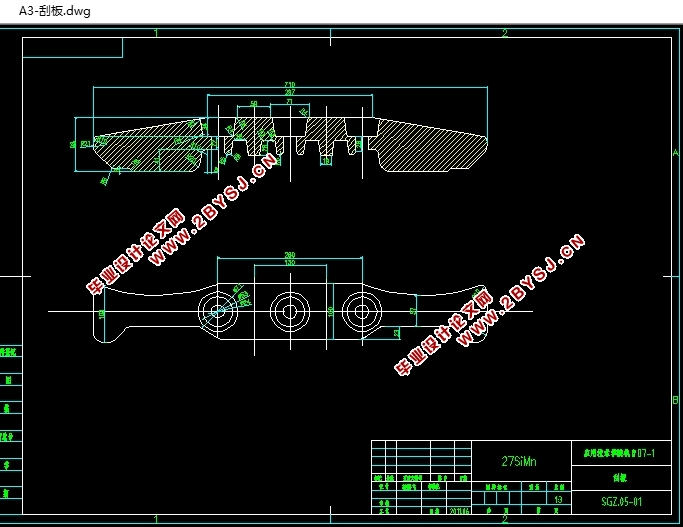

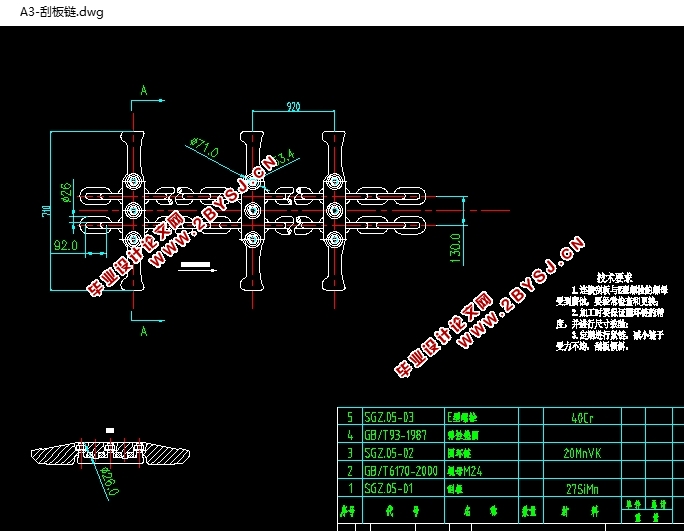

2.4刮板链 9

2.5紧链装置 10

2.6推移装置 11

2.7锚固装置 11

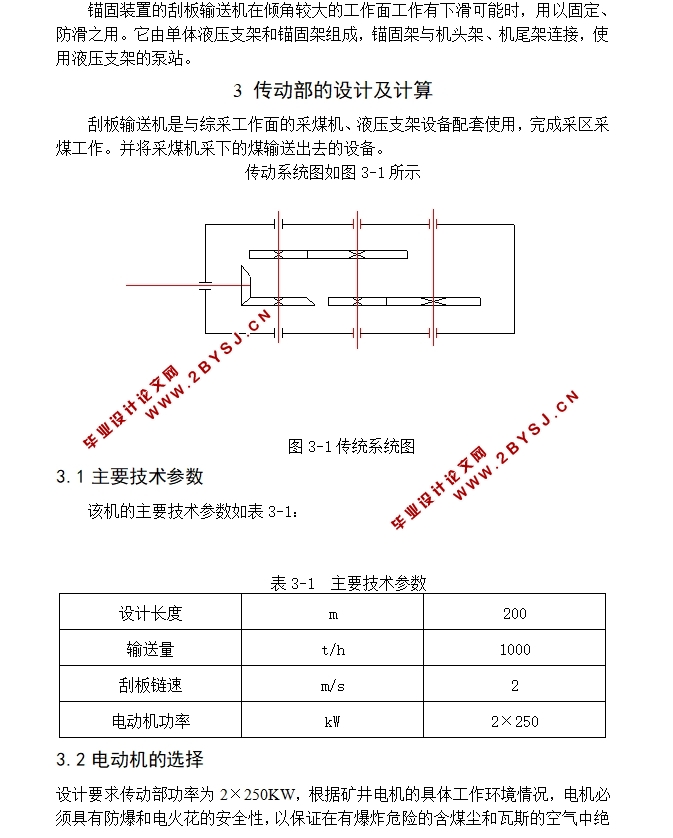

3 传动部的设计及计算 12

3.1主要技术参数 12

3.2电动机的选择 12

3.2.1运输能力计算 13

3.2.2估算减速器的输出转速 13

3.3总传动比及传动比的分配 14

3.3.1总传动比的确定 14

3.3.2传动比的分配 14

3.4传动部传动计算 14

3.4.1各轴转速计算 14

3.4.2各轴功率计算 15

3.4.3各轴扭矩计算 15

3.4.4第一级圆锥齿轮传动的计算 16

3.4.5第二级圆柱齿轮传动的计算 20

3.4.6第三级圆柱齿轮传动的计算 24

3.5轴的结构设计与校核 29

3.5.1Ⅰ轴的结构设计及校核 30

3.5.2Ⅱ轴的结构设计及校核 33

3.5.3Ⅲ轴的结构设计及校核 36

3.5.4Ⅳ轴的结构设计及校核 39

3.6键的设计与强度校核 43

3.6.1普通平键 43

3.6.2花键 44

3.7 减速器轴承的校核 47

3.7.1 验算Ⅰ轴轴承寿命 47

3.7.2验算Ⅱ轴轴承寿命 48

3.7.3验算Ⅲ轴轴承寿命 48

3.7.4 验算输出轴轴承寿命 49

4 刮板输送机的使用和维护 50

4.1润滑及注油 50

4.2重型刮板输送机的安装、运行与维护 50

4.2.1重型刮板输送机的安装与试运转 50

4.2.2刮板输送机的运行注意事项 52

4.2.3常见故障及处理方法 52

4.2.4刮板输送机的常规保养及维护 53

4.2.5刮板输送机上使用的新型传动系统 55

结 论 56

参考文献 57