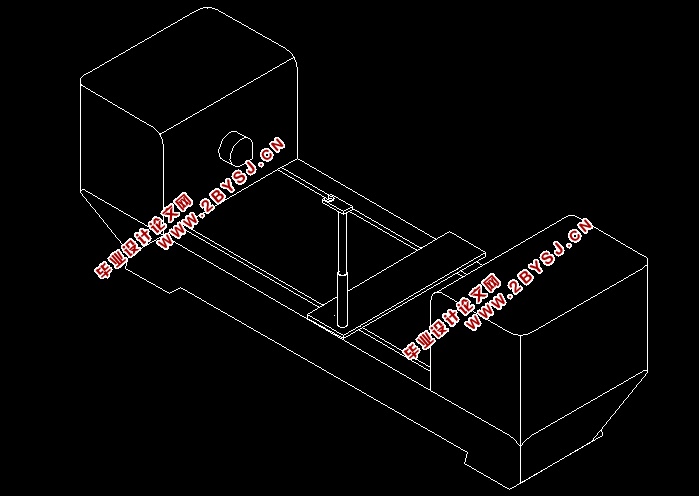

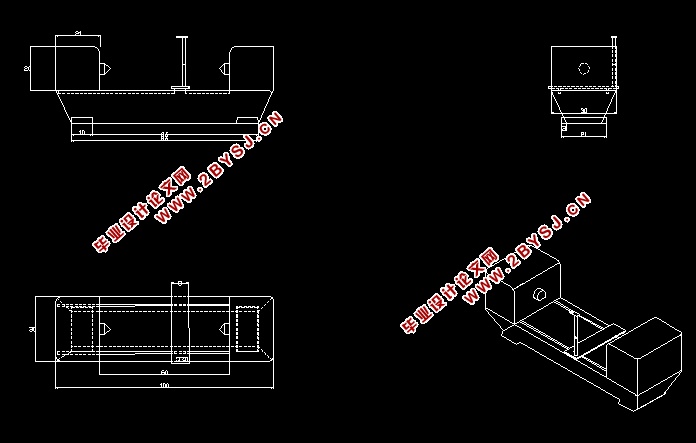

用于检测全跳动的偏摆检查仪设计(含CAD工件图)

无需注册登录,支付后按照提示操作即可获取该资料.

用于检测全跳动的偏摆检查仪设计(含CAD工件图)(外文翻译,论文说明书12000字,CAD图1张)

摘要:本课题拟对原有偏摆检查仪进行改进,扩展其功能,设计能满足检测径向和端面全跳动项目的实验装置。用以测量实际被测要素对理想回转面的允许变动量。解决了在实际使用对整个表面的形位公差综合控制,并且测量简便。

本课题针对此问题设计了一种全新的偏摆检查仪,通过资料查询,文献参考,对原有的偏摆检查仪进行结构分析,设计出用于检测全跳动的偏摆检查仪。新的偏摆检查仪和原有的偏摆检查仪相比具有结构稳定,操作简单,精度高等优点。它不仅能反映单个测量面内被测要素轮廓形状的误差情况,而且能反映整个被测面上的误差。更加的贴近实际。

本课题通过对偏摆检查仪的改进与设计,得出了偏摆检查仪能够提高企业生产效率,提高产品精度的结论。测量仪器的测量方式的改进,不仅可以提升机械加工生产的效率,而且可以极大的改善人们的工作形式,对建设科技强国也具有重要作用。

关键词:全跳动; 偏摆检查仪;测量仪器。

Bounce tester design for detecting full runout

Abstract:This subject intends to improve the original yaw tester, expand its function, and design an experimental device that can meet the radial and end-to-end full jerk. It is used to measure the allowable variation of the ideal revolution surface for the actual measured element. Solve the practical use of the whole surface of the geometric tolerance control, and measurement is simple.

This subject has designed a new type of pendulum tester for this problem. Through data query and literature reference, the structural analysis of the original pendulum tester is designed to design a pendulum tester for detecting full runout. Compared with the original pendulum tester, the new pendulum tester has the advantages of stable structure, simple operation and high precision. It can not only reflect the error of the contour shape of the measured element in a single measurement plane, but also reflect the error of the entire measured surface. More close to reality.

This subject through the improvement and design of the pendulum tester, concluded that the pendulum tester can improve the production efficiency of the company and improve the accuracy of the product. Improvements in the measurement methods of measuring instruments can not only improve the efficiency of mechanical processing and production, but also can greatly improve people's working methods, and also have an important role in building a strong science and technology nation.

Keywords:Full beat,Bending tester,Measuring instrument

目 录

摘要 I

Abstractt II

1绪 论 1

1.1研究的目的及意义 1

1.2国内外研究状况 1

1.3主要研究内容 2

1.4 研究的方法及步骤 2

2结构设计 3

2.1全跳动偏摆检查仪的技术条件及其原理 3

2.1.1全跳动与全跳的公差的概念 3

2.1.2圆跳动的概念及与全跳动的区别 3

2.1.3各公差项目的详细检测方案 4

2.2偏摆检查仪的基本结构设计 4

2.2.1确定结构 4

2.2.2全跳动偏摆检查仪的工作原理 5

2.3底座与尾座的设计 5

2.4测量机构的设计 6

2.5变换机构的设计 6

2.6位移传感器的选择 6

3设计计算 8

3.1电动机的设计 8

3.1.1电动机的容量 8

3.1.2电动机的转速 8

3.2计算传动装置的运动和动力参数 8

3.2.1传动装置的传动比 8

3.2.2各轴转速,输入功及扭矩 9

3.3齿轮的设计 9

3.3.1选定齿轮精度等级,材料,齿数和模数 9

3.3.2齿面接触强度计算 9

3.3.3按齿根弯曲疲劳强度设计 10

3.3.4几何尺寸计算 12

3.4滚珠丝杠的计算 12

3.4.1确定滚珠丝杠副的导程 12

3.4.2滚珠丝杠的载荷及转速计算 12

3.4.3估算丝杠的最大允许轴向变形量 13

3.4.4计算滚珠丝杠长度及螺纹底X 13

3.4.5确定滚珠丝杠副的规格代号 14

4精度与误差计算 15

4.1误差分析 15

4.2在垂直平面的直线度误差而引起的误差 15

4.3在水平面的直线度误差而引起的误差 16

4.4装置精度设计 16

5三维模型绘制 18

5.1UG绘图软件介绍 18

5.1.1UG介绍 18

5.1.2UG的特点 18

5.2零件的建模 18

5.2.1底座的建模 18

5.2.2头架的建模 19

5.2.3测量机构的建模 20

5.3零件的装配 21

结 论 22

参考文献 23

致 谢 24

附录A 外文翻译 25