小型油渣压块机设计(含CAD零件装配图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

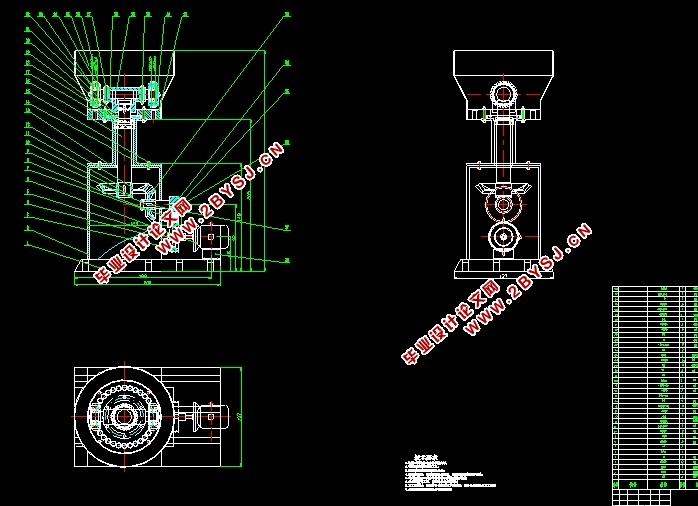

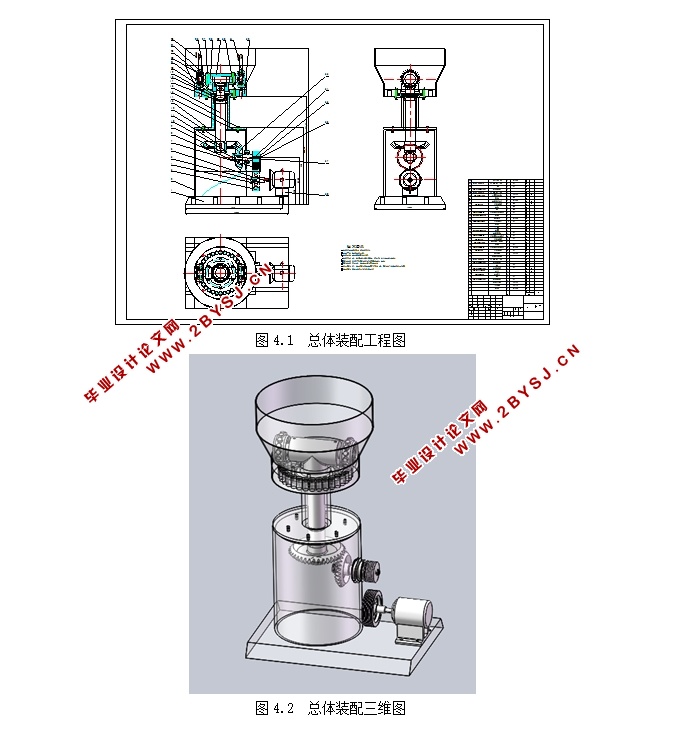

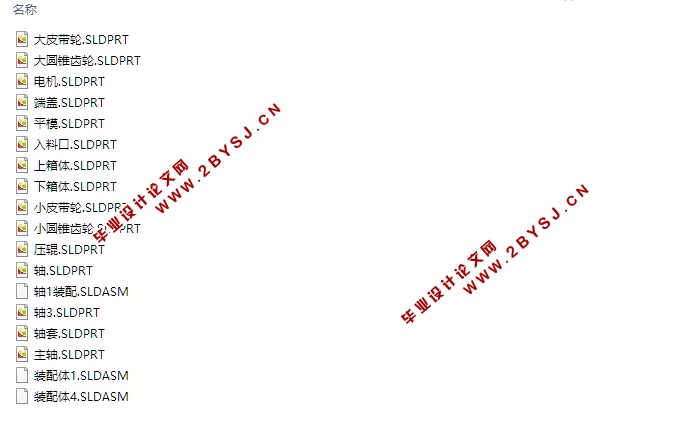

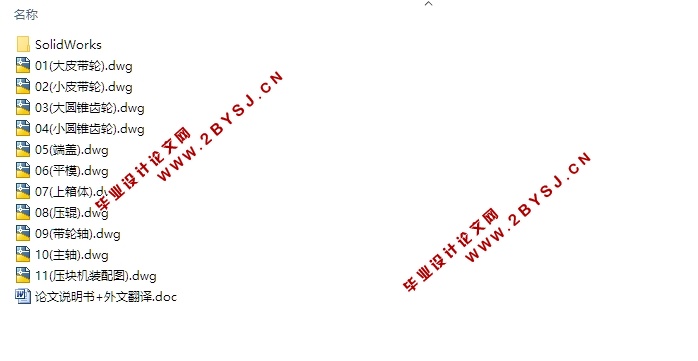

小型油渣压块机设计(含CAD零件装配图,SolidWorks三维图)(论文说明书11000字,外文翻译,CAD图纸11张,SolidWorks三维图)

摘要

中国经济发展的趋势必定是发展低碳经济,减少二氧化碳排放。着力打造低耗、低排、节约能源的低碳经济势在必行。中国十多亿人口的现状下,食用油的消耗是巨大的,因此榨油是能源耗费大户,而榨油所产生的废料则需要大量的处理。因此,打造“低碳经济”,油渣压块机的设计义不容辞。

本文设计的题目是油渣压块机的设计。油渣压块机压出的产品是用来做饲料或肥料的。经过实践和不断的改进,油渣压块机已日臻完善。油渣压块机具有自动化程度高、产量高、价格低、耗电少、操作简单、环境无污染等优点。因而油渣压块机可广泛应用压制各种榨油物榨油后所剩的渣滓。

本文在通过了解国内、国外各种类型的压块机之后,利用简化力学模型计算了油渣压块机的主要技术参数,通过分析机器工作时所需的动力来确定电动机的选择,平模和压辊组成的碾压装置的设计,并对油渣压块机的传动系统进行设计,主轴的尺寸、长度、结构的确定以及强度校核等,完成用于压缩油渣的油渣压块机。

关键词:平模压缩成型技术、低碳经济、压块机

ABSTRACT

The trend of China’s economic development must be to develop a low-carbon economy and reduce carbon dioxide emissions. It is imperative to focus on building a low-carbon economy with low consumption, low emissions, and energy conservation. Under the current situation of more than one billion people in China, the consumption of edible oil is huge, so oil extraction is a big energy consumer, and the waste generated by oil extraction requires a lot of processing. Therefore, to create a "low-carbon economy", the design of the oil residue briquetting machine is incumbent.

The design of this paper is the design of the oil residue briquetting machine. The product pressed by the oil residue press is used for feed or fertilizer. After practice and continuous improvement, the oil residue briquetting machine has been improved. The oil dregs briquetting machine has the advantages of high automation, high output, low price, low power consumption, simple operation, and no environmental pollution. Therefore, the residue press can be widely used to suppress the residue left after pressing various oils.

This article through the understanding of domestic and foreign various types of block making machine, using the simplified mechanics model for calculating the main technical parameters of diesel block making machine, through the analysis of the power of machine work required to determine the choice of motor, flat die and roller, roller compaction device design, and the drive system of diesel block making machine to carry on the design, the determination of the size, length, structure, main shaft and strength check, etc., used to compress diesel diesel block making machine.

Keywords: flat die compression molding technology, low carbon economy, briquetting machine

目 录

摘要 1

ABSTRACT 2

绪论 1

1 选题的背景意义 1

2 油渣压块机的概述 1

2.1 油渣压块机的工作原理 2

2.2 油渣压块机的工作性能 2

3 油渣压块机分类及性能比较 2

4 压块机的发展趋势 5

1 油渣压块机设计方案及参数的确定 6

1.1 压块机机身方案的确定 6

1.2 压块机整体传动方案的选择 6

2 油渣压块机动力参数及传动比的确定 7

2.1 电动机的选择 7

2.2 传动比的计算及分配 9

2.2.1 传动比的计算 9

2.2.2 传动比的分配 10

3 油渣压块机主要零件的设计及校核 11

3.1 V带的设计及校核 11

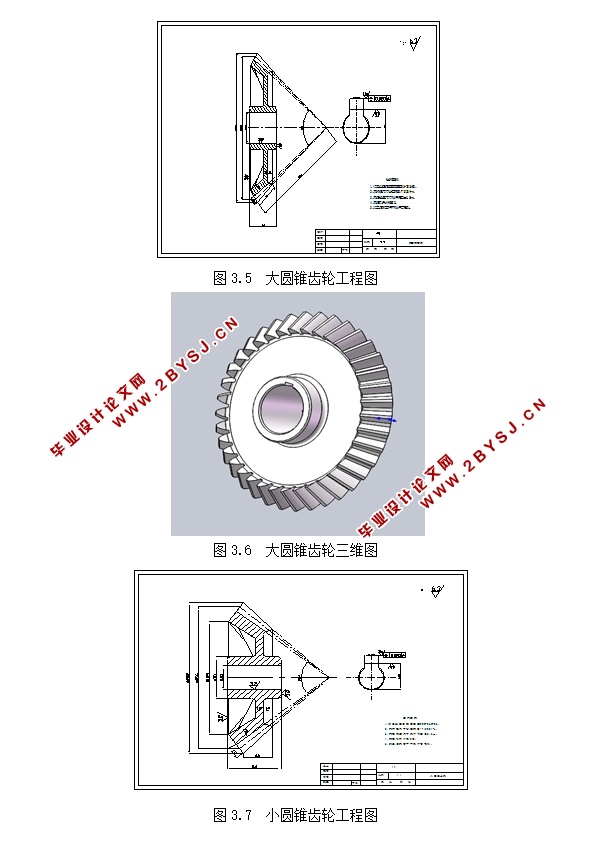

3.2 锥齿轮减速传动的设计及校核 14

3.3 主轴的设计及校核 16

3.3.1 主轴的材料的选择 17

3.3.2 主轴结构的设计 17

3.3.3 轴各轴段结构的确定 17

3.3.4 轴的强度校核 19

3.4 油渣压块机平模的设计 20

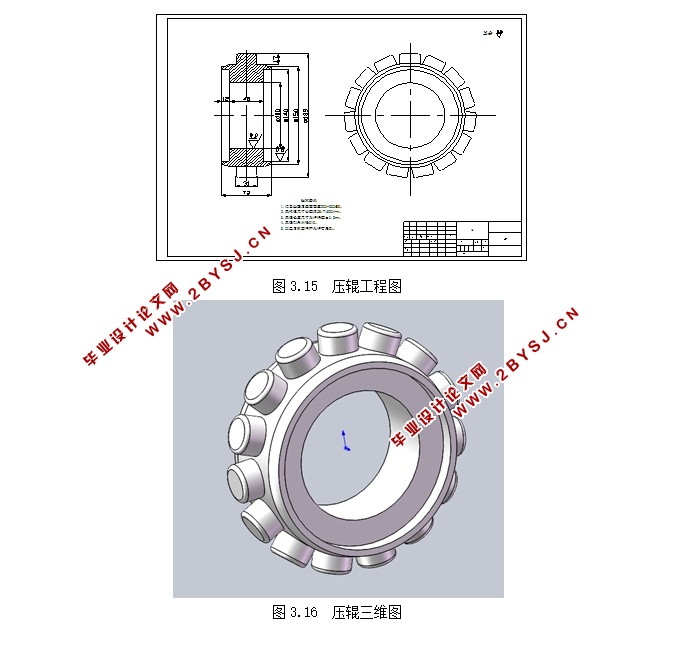

3.5 油渣压块机压辊的设计 21

4 结论 23

参考文献 25

附录1:外文翻译 26

附录2:外文原文 30