一种加工中心水平轴驱动装置设计(含CAD图)

无需注册登录,支付后按照提示操作即可获取该资料.

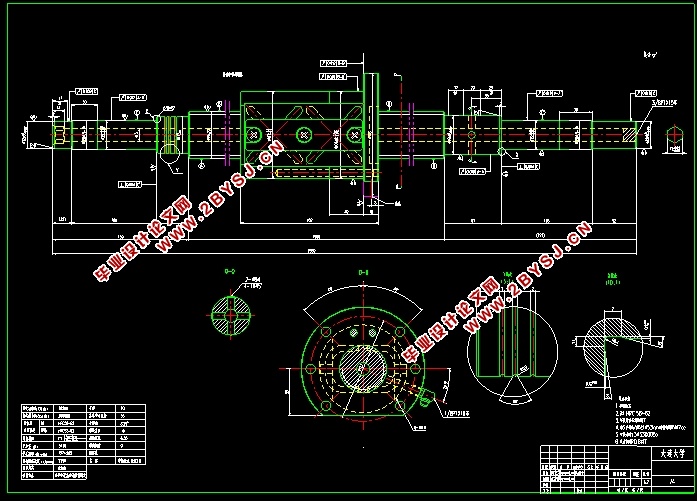

一种加工中心水平轴驱动装置设计(含CAD图)(论文说明书1000字,外文翻译,CAD图纸15张)

摘要

装备制造业是为国民经济各行业提供加工装备的基础产业,其上下游产业链长、提供就业岗位多、技术资金密集,是各行业实现加工能力升级、产品进步的重要保障和国家综合实力的集中体现。经过多年发展,我国装备制造业已经形成门类齐全、规模较大、具有一定技术水平的产业体系,成为国民经济的重要支柱产业。但以卧式加工中心为代表的具有高性能、高自动化、高附加值的高端数控机床却远远落后于装备制造业发达国家。在世界产业格局调整、国内机床市场需求持续增长、以及国家加快振兴装备制造业的关键时期,开发高性能的卧式加工中心势在必行。

本文以MDH125卧式加工中心机械结构为主体进行了研究。MDH125卧式加工中心是大连机床集团有限责任公司开发生产的具有国内领先水平,国际先进水平的卧式加工中心之一,该机床广泛适用于军工、航天、汽车、模具、机械制造等行业的箱体零件、壳体零件、盘类零件、异形零件的加工,零件经一次装夹可自动完成四个面的铣、镗、钻、扩、铰、攻丝的多工序加工。

论文结合企业卧式加工中心新产品的开发,简要论述了一种加工中心水平轴的驱动装置设计方案。依据国内外多款优秀卧式加工中心的机床参数,综合考虑市场需求、市场竞争力、企业产品结构等因素,确定了设计的初始参数;分析各种卧式加工中心结构布局,综合考虑整体刚性、机床性能、制造成本、操作方便等因素,确定切合实际的方案。

关键字:卧式加工中心;水平轴;驱动装置

Abstract

The equipment manufacturing industry is the basic industry which provides the processing equipment for the national economy each profession, its upstream and downstream industry chain is long, provides the employment post many, the technology capital is dense, is each profession realizes the processing ability to upgrade, The important guarantee of product progress and the concentrated embodiment of national comprehensive strength. After years of development, China's equipment manufacturing industry has become an important pillar industry of the national economy. However, the advanced NC machine tools with high performance, high automation and high added value, represented by horizontal machining center, lags far behind the developed countries in equipment manufacturing. In the key period of adjusting the world industrial pattern, increasing the market demand of domestic machine tools and speeding up the revitalization of the equipment manufacturing industry, it is imperative to develop a high performance horizontal machining center. In this paper, the mechanical structure of MDH125 horizontal Machining Center is studied. MDH125 horizontal Machining Center is one of the leading horizontal machining centers with domestic and international advanced level, which is developed and produced by Dalian Machine tool Group Co., Ltd. The machine tool is widely used in the processing of box parts, shell parts, disk parts and special-shaped parts in the fields of military industry, aerospace, automobile, mould, machinery manufacturing and so on. The parts can be milled, boring, drilling, expanding and hinging automatically after a single clamping. Multi-process processing of tapping. Combined with the development of new products of horizontal machining center, a design scheme of driving device for horizontal axis of machining center is briefly discussed in this paper. According to the machine tool parameters of many excellent horizontal machining centers at home and abroad, considering the market demand, market competitiveness, product structure and other factors, the initial design parameters are determined, and the structural layout of various horizontal machining centers is analyzed. Considering the overall rigidity, machine performance, manufacturing cost, easy to operate and other factors, to determine the practical scheme.

Keywords: horizontal machining center; horizontal axis; driving device

目 录

1.绪论 1

1.1设计背景 1

1.2选题意义 1

1.3国内外研究现状 2

1.4设计所做的工作 3

2.主要卧式加工中心分类及初始参数选定 4

2.1 低速大扭矩型 4

2.2 中速适用型 5

2.3 高速加工型 5

2.4 加工中心选型及其初始参数的拟定 6

3.驱动系统理论分析 8

3.1 主传动功率的选定方法 8

3.2 主传动功率–扭矩特性分析 8

4.驱动系统结构原理及设计 12

4.1 电主轴结构原理及设计 13

4.2 齿轮主轴结构原理及设计 14

5.结论 18

附录1:外文翻译 20

附录2:外文原文 24

致 谢 29