犁式卸料器设计(含CAD零件装配图,CAXA图)

无需注册登录,支付后按照提示操作即可获取该资料.

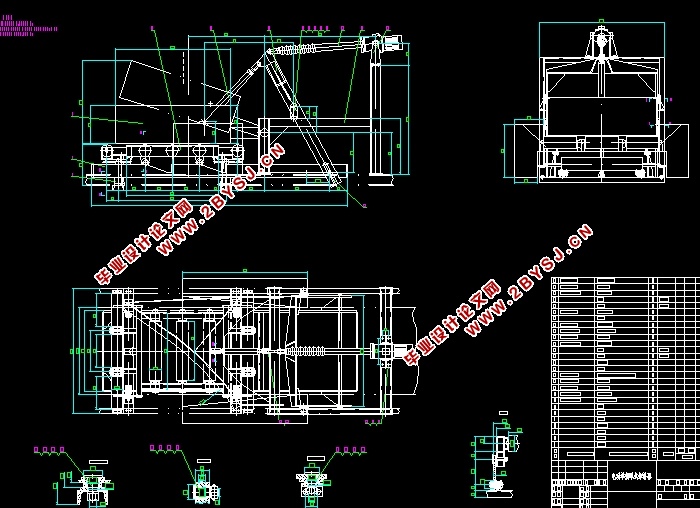

犁式卸料器设计(含CAD零件装配图,CAXA图)(开题报告,论文说明书7700字,CAD图纸10张,CAXA图纸10张)

摘要

随着矿业不断地开发,普通的卸料器结构复杂、控制复杂、卸料效率较低;而且,远远达不到实际的工作要求,影响工作的效率;为了推动新型卸料机的研发设计。目前,犁式卸料机出现,在卸料器占有重要的地位;目前,犁式卸料器进一步摆出克服了所有电动老式卸料器的缺点,进一步可以调整犁头的角度,保证传送机的稳定性;改进了前后双犁头、单犁头、液压驱动不同的实用结构,大大提高了工作的效率;所以,犁式卸料机是现在我国最先进、最实用的卸煤分矿机械结构。

近几十年来,这一种“犁式卸料器”新型设备,主要适用大量煤矿的生产。它的结构简单,操作灵活,直观感觉好,制造、维修方便,在生产中已逐步得到推广,受到客户的青睐。

电液犁式卸料器工作原理[1]:以电动机把输出的机械能通过液压系统(液压缸、驱动杆等结构)转化液压能,再有液压能驱动液压推杆把液压能转化为机械能,带动框架前,促使犁头组合进行卸料工作。电液犁式卸料器工作时,液压推杆推动作用于驱动杆,带动框架前进,完成犁刀下落与上升状态;并且,支撑起平托辊组机械机构,使固定式运输机的皮带工作面平直,使犁头下降到沿与固定式传送带皮带面贴合紧密。然后,煤料料行卸入漏斗。同时,由原煤堵塞的优质煤形成的原因进行了系统的分析,与深刻的研究;故提出了犁式卸料器在原煤仓防堵中的运用方案,将电液动双侧犁式卸料器改造成犁式卸料器后,解决发生过严重堵煤现象,此方案适用于任何品质及水分含量的原煤 。

犁式卸料器对原煤提纯的重要的作用;而且,犁式卸料器还可以去除尘机械设备,对原煤等矿产的生产大大的提高了工作的效率。我设计的犁式卸料器主要是对犁式卸料器总体设计分析;其次,对犁式卸料器适合的的传送机的选择与其个性能参数计算;再者,重点分析是对其机械结构受力分析与设计改造以及设计,进一步有限元分析分析;最后,是对液压结构才用的运用、电动推杆的选择分析电机的选择以及机架机构的焊接等。还又对该电液动犁式卸料机部分结构设计等等,通过该毕业设计让自己对卸料器机械结构受力有更深入了解。同时,卸料器机构在我国工业时代发展中不可缺少的,我们需要不懈的努力创新,共创工业2025的发展。

关键词:电液动犁式卸料器;原理;卸料器机械结构力学分析

Abstract

With mining industry continue to develop, the ordinary unloading feeder is far less than the actual work requirements, affect the work efficiency; thus, promote the emerging of the unloading machine R & D and design. At present, the electric hydraulic plough type unloader occupies an important position; plough type unloader further set out to overcome the all electric old-fashioned discharger shortcomings. At present, the improvement of the front and rear double ploughshares, electro-hydraulic type, such as different practical structure; therefore, it is now the most advanced, the most practical unloading material structure of mine machinery.

In the past 20 years, the a new device "electric hydraulic plough type unloader, suitable for the production of a large number of coal mine. It has the advantages of simple structure, flexible operation, good visual feeling, manufacturing, convenient maintenance, in production has been applied gradually. Welcomed by workers.

Analysis of the formation of unloading is closely clung to the group, and the working principle of electric hydraulic plough type unloader [1] to motor output mechanical energy through a hydraulic system (hydraulic cylinder structure) into hydraulic energy, another hydraulic drive hydraulic push rod for dynamic execution. Electro hydraulic plough type unloader, hydraulic push rod driving role in driving rod with dynamic frame forward and complete Coulter falling state support Pinto and mechanical mechanism, so that the conveyor belt surface is flat, and the colter falls along with the belt surface, and then, the conveyor belt on the aggregate into the funnel (hopper), or removing the need to place. At the same time, in Heshan Power Plant coal bunker coal blockage, and puts forward The single side plough type unloading feeder in the coal bunker against blocking in the application program, electric hydraulic bilateral plow type material for retrofit into unilateral plough unloader, Heshan Power Plant did not happen serious coal blockage accident, this scheme applicable to any quality and moisture content of coal .

In the choice of analysis is suitable for unilateral unilateral unilateral unilateral electro hydraulic plough type unloader of coal purification of important role; and electro hydraulic plough type unloader can also to dust removal equipment of coal and other mineral production greatly improves the work efficiency, I design the electro - hydraulic plough type unloader is mainly of electric liquid single side plough type unloader overall design analysis; secondly, the electro - hydraulic plough type unloader conveyor selection and personality parameters calculation; moreover, focuses on the analysis of the mechanical structure stress analysis and design improvement and design, further finite element analysis; finally, the hydraulic structure with the use of the electric push rod motor Mechanism and a machine frame welding. And on the electric hydraulic plough type unloader part structure design, and so on, through the graduation design let oneself the unloader machinery structure stress more in-depth understanding of. At the same time, unloading feeder institutions in China's industrial development is an indispensable, we need unremitting efforts on innovation, create 2025 industrial development.

Keywords: electric hydraulic plough type unloader; principle; unloader mechanical structural mechanics analysis;

犁式卸料器的工作原理

1.犁式卸料器工作过程是以电动机驱动液压缸推动执行元件为动力源;并且,把电动机的机械能通过电液推杆做动力驱动源,满足了手动或电动卸料器犁料承载能力差,是卸料时传送带更加稳定,是实现无极调速,调节了犁头的卸料能力;同时,也避免了动力不足,涡流烧毁电机,丝杠顶弯,机械机构装置易损坏的不足工作时通过推杆伸出驱动杆.(式犁式卸料器的动作原理见图3.1所示)

2.液压传动的优点:

3.液压传动系统能够实现无级调速,传动比的范围在 ,故调速范围较大。

2.液压传动系统实现过载保护短路保护,能够防止电动机烧坏,同时,液压系统的安全阀可防止过载。运转平稳,容易吸收机构带来的冲击和振动。

3.液压传动系统和机械传动、电动传动装置相比,在等功率条件下重量轻、体积小。因此惯性小、动作灵敏,可实现频繁启动和换向。

4.液压传动能够实现往复直线传动。由于输出机械功率比较大、液压传动总体的体积比较小、在狭小的空间里做复杂的往复运动。液压传动的这一特点能坐在数控机床、加工中心、组合式钻床以及线形切割等等机床中,起着非中重要的作用。

5.液压传动易于操纵,加上自动控制系统,有较好的效果,能实现工业的自动化,起着重要的作用。

目录

一 摘要...................................................................................................3

二 犁式卸料器概述................................................................9

三 犁式卸料器的工作原理....................................................8

四 犁式卸料器的的结构特点与使用情况..............................8

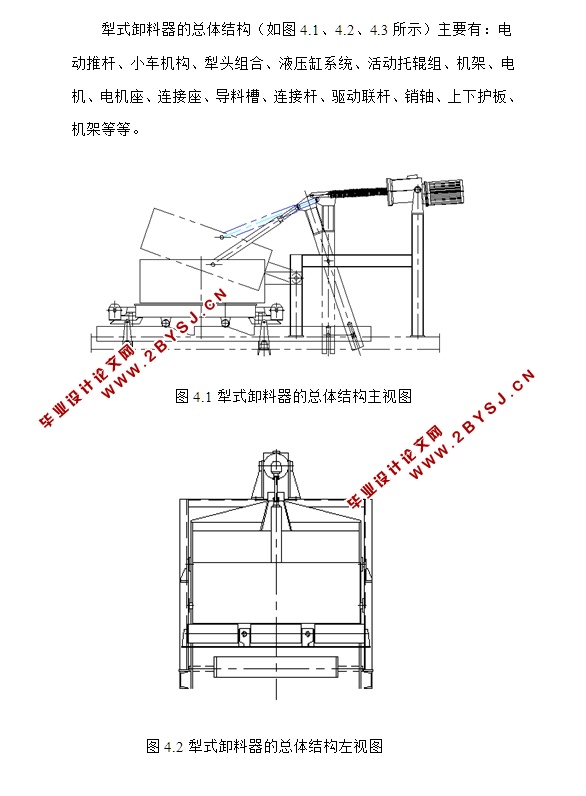

4.1 犁式卸料器的结构特点.............................................10

4.2犁式卸料器的总体结构组成......................................11

五 犁式卸料器结构分析与计算............................................12

5.1 犁式卸料器总体要求与结构分析.............................12

5.1.1 犁式卸料器总体要求..............................................12

5.1.2犁式卸料器总体结构分析.......................................13

5.2 固定式带式输送机选择............................................................12

5.2.1DTII型固定式带式输送机的运用范围与技术参数...............13

5.2.1.1DTII型固定式带式输送机的运用范围................................14

5.2.1.2DTII型固定式带式输送机的技术参数.................................17

5.2.2 DTII型固定式带式输送机的机构分析..................................19

5.3犁式卸料器力学分析..................................................19

5.4 犁式卸料器部分结构设计.........................................21

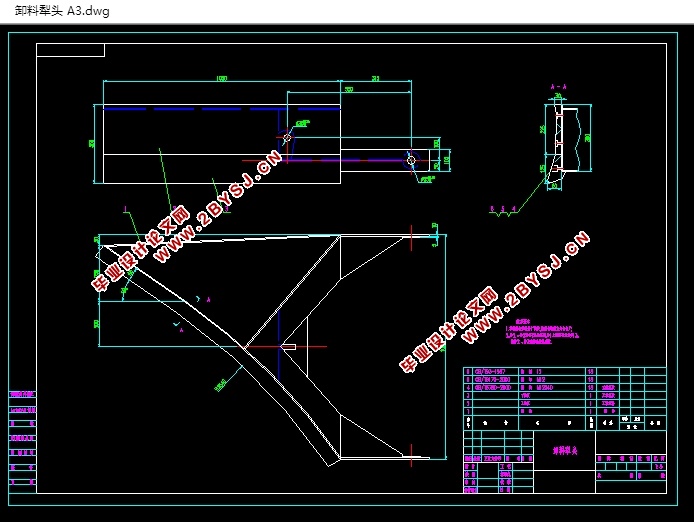

5.5.1卸料器卸犁头...........................................................................22

5.5.2 卸料器下部托架......................................................................25

5.5.3卸料器托辊组..........................................................................26

5.5.4 电动推杆的选择.................................................................30

5.5.5 电动机的选择...................................................................32

5.5.6犁式卸料器结构的焊接...................................36

5.5.7卸料器工作参数计算..........................................................24

六 总 结 ......................................................................................42

七 参考文献........................................................................................44

八 谢 辞.............................................................................................46