基于MATLAB管式加热炉的模糊控制系统设计(附程序)

无需注册登录,支付后按照提示操作即可获取该资料.

基于MATLAB管式加热炉的模糊控制系统设计(附程序)(课题申报表,任务书,开题报告,中期检查表,外文翻译,论文25000字,程序,答辩PPT)

摘 要

管式加热炉是石油炼制、石油化工和化学、化纤工业装置中所使用的具有提供热源的火力加热设备,加热炉内安装有无缝钢管连接而成的管排,被加热物质在管内流动,被加热到工艺要求的温度。将物料加热到工艺要求温度是加热炉控制系统的基本控制要求,但针对目前存在的能源危机,提高加热炉的热效率,通过加热炉优化控制从而更好地做到节能减排则更具有实际意义。

本文基于加热炉多变量、时变、非线性、强耦合、大惯性特性的考虑,跳出了以完全依赖数学模型为基础的控制框架,结合国内外加热炉的控制方法和控制现状,针对加热炉系统中的温度参数控制进行研究。

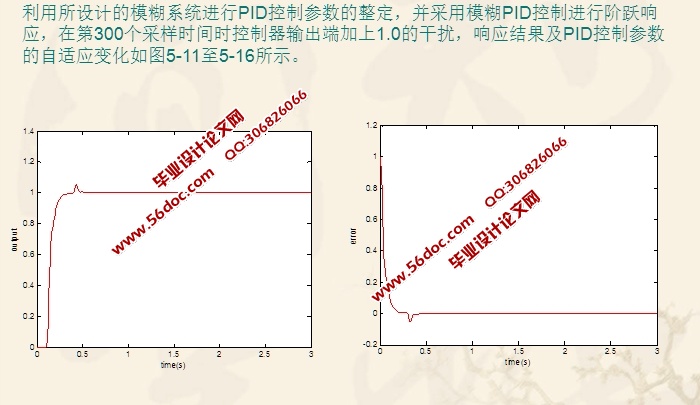

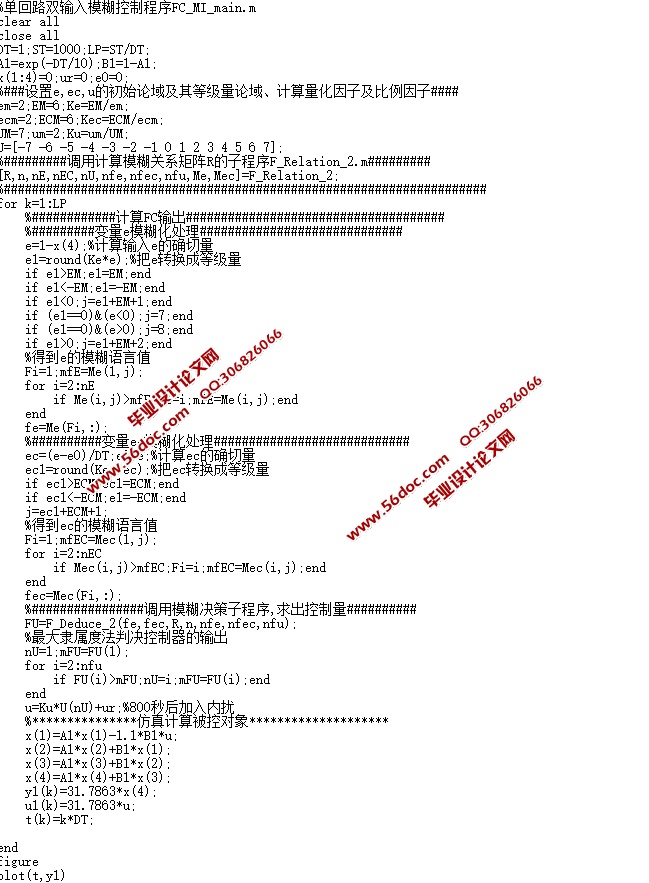

首先,介绍了课题的研究背景和意义,总结了国内外管式加热炉的研究现状,叙述了管式加热炉的一般结构、主要技术指标和主要控制参数,总结了管式加热炉的控制难点;然后,论述模糊控制器基本理论,介绍了模糊控制器的两种类型:单变量模糊控制器和多变量模糊控制器,并叙述了模糊控制器的设计过程,实现一步模糊控制算法的过程;然后,采用以模糊控制为核心的控制方案:双输入模糊控制,利用Mallab进行实验仿真,从仿真结果可以看到,双输入模糊控制器能使系统快速达到稳定,但是,仍然存在很大的静差。针对这一情况,将模糊控制和PID控制相结合构成复合控制器,发挥两种控制器的优点,模糊子整定PID具有超调量小,响应迅速,调节时间短等优点,且具有良好的鲁棒特性。更加稳定、快速地达到预期的目标值,且误差范围小。

关键词:管式加热炉;模糊控制;模糊自整定

Abstract

Tube furnace oil refining, petrochemical and chemical, chemical industry equipment used in the heat of the fire has provided heating equipment, seamless steel pipe installed inside the furnace exhaust connection is made, the heated material flow in the pipe , the process is heated to the required temperature. The material is heated to the required temperature is the basic process control requirements furnace control system, but for the existing energy crisis, improve the thermal efficiency furnace, furnace optimization control in order to better achieve through energy conservation is more meaningful .

Based on multivariate furnace, time-varying, nonlinear, strong coupling, considering the characteristics of large inertia, jumped out to rely entirely on a mathematical model based control framework, combined with the control method and control the status of domestic heating furnace for heating furnace The temperature control system parameter studied.

Firstly, the research background and significance of the subject, summarizes current research tube furnace, described the general structure of the tube furnace, the main technical indicators and the main control parameters, summed up the difficulty tubular heater control ; then discusses the basic theory of fuzzy controller, describes two types of fuzzy controllers: univariate and multivariate fuzzy controller fuzzy controller and describes the design process of the fuzzy controller, fuzzy control algorithm to achieve step process; Then, the control scheme to fuzzy control as the core: Dual input fuzzy control, use Mallab simulation experiment, the results can be seen from the simulation, dual-input fuzzy controller enables the system to quickly reach stable, but there is still a lot of static poor. For this case, the fuzzy control and PID control are combined to form composite controller to play the advantages of both controllers, fuzzy tuning PID has a small overshoot, fast response, regulating short time, etc., and has good Lu stick properties. More stable, quickly achieve the desired target value, and the small error range.

Keywords: tube furnace; fuzzy control; fuzzy self-tuning

目 录

第1章 绪论 1

1.1 课题研究背景和意义 1

1.2 加热炉控制现状 2

1.3 本文主要研究内容 5

第2章 管式加热炉系统 7

2.1 管式加热炉的一般结构 7

2.2 管式加热炉主要技术指标 10

2.3 主要控制参数 11

2.4 管式加热炉控制难点 13

2.5 本章小结 14

第3章 管式加热炉的模糊控制器设计 15

3.1 模糊控制概述 15

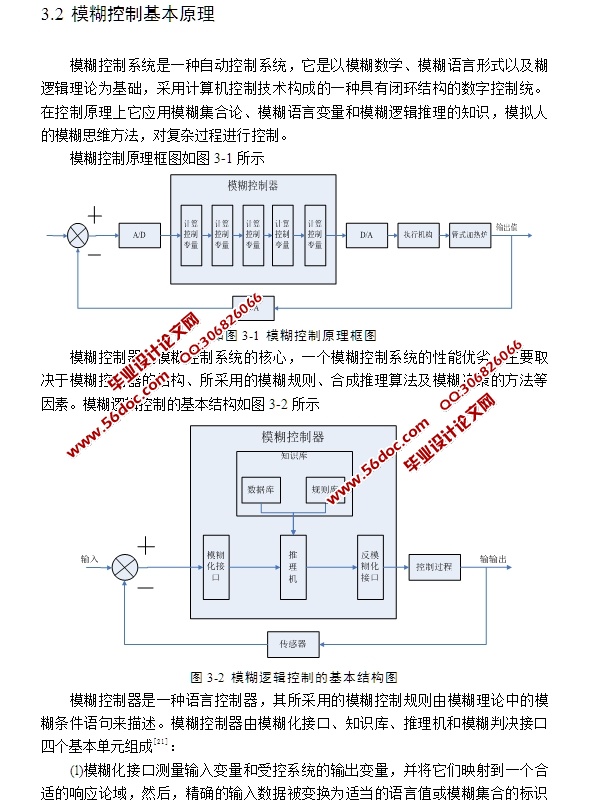

3.2 模糊控制基本原理 16

3.3 管式加热炉模糊控制器类型 17

3.4 模糊控制器的设计 19

3.5 本章小结 22

第4章 管式加热炉出口温度模糊控制设计 23

4.1 仿真软件功能描述 23

4.2 管式加热炉数学模型 23

4.3 管式加热炉温度的模糊控制器设计与仿真 25

4.4 本章小结 29

第5章 加热炉的模糊自适应整定PID控制器设计 30

5.1 经典PID控制 30

5.2 模糊自适应整定PID控制器 31

5.3 管式加热炉温度模糊整定PID控制仿真 33

5.4 本章小结 40

结论 41

参考文献 42

致谢 44

附录 45