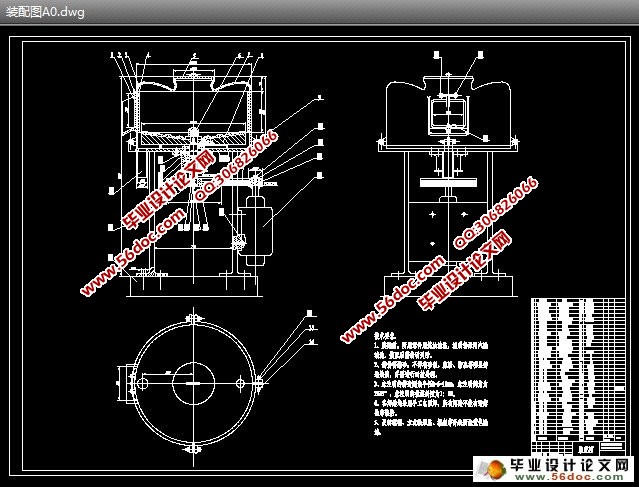

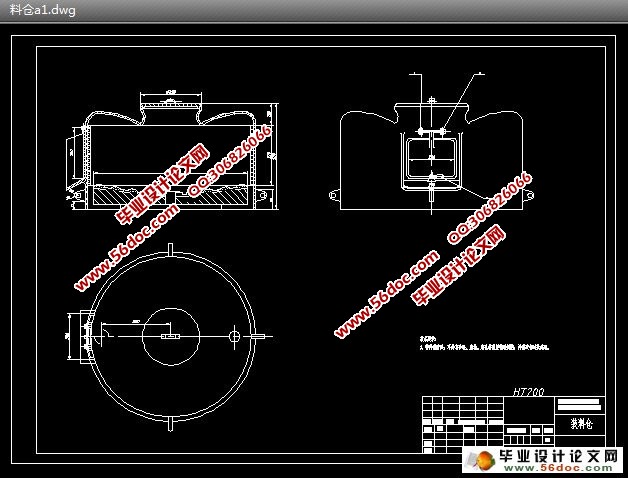

红薯去皮机的设计(含CAD零件图和装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

红薯去皮机的设计(含CAD零件图和装配图)(选题审批表,任务书,开题报告,中期检查表,论文说明书12000字,CAD图6张)

摘 要:主要介绍了以摩擦原理为基础的、适合食品加工工厂等场所使用的红薯去皮机的设计要点、工作原理和设备组成。不管任何形式的红薯加工,去皮都是一项重要的操作环节。因此,根据不同需求,开发了一系列的红薯去皮机。它们的性能也被不断的评估。去皮用于多种水果和蔬菜的加工中以除去不需要或不可食的物质,并改善成品的外观。主要的考虑因素包括通过尽可能减少去掉的部分以及可能降低能源、劳力和物质成本来降低总成本。这里,介绍摩擦去皮方法:食品被放置在金刚砂滚轴上或内壁排列着金刚砂的转筒中,在磨损力的表面除去食品的表皮后又被大量的水冲洗干净。该方法的优点是由于过程是在温室下进行而具有的能源成本低以及资本成本低、无热损伤,食品外观良好的优点,不规则食品表面(如红薯上的“孔眼”)会破坏去皮产品的外观,需要手工去除。

关键词:红薯去皮机;摩擦;去皮;传动

THE DESIGN OF THE SWEET POTATO PEELERS

Abstract:Mainly introduces the principle based on friction, suitable for food processing factory and other places of use of the sweet potato skin-peeling-off machine the main points of design, working principle and composition of equipment. No matter in any form of sweet potato processing, to age is an important part of the operation. Therefore, according to the different demand, the development of a series of sweet potato skin-peeling-off machine. Their performance was constant evaluation.Skin peeling (for) of fruits and vegetables processing to remove need not eat or not, and improve the physical appearance of the product. The main factors including through minimize removed part and may reduce the labor and material costs energy, reduce the total cost. Here introduces friction peel method: food is placed on the walls or emery roller drum lined up in the emery, wear away the food of skin surface by the amount of water after washing clean. The advantage of this method is due process is conducted in greenhouse with low cost and the energy of capital cost is low, no heat, the advantages of good food appearance, irregular food surfaces (sweet potato "holes) destroys peel product appearance, need manual removal.

Key Words:sweet potato;friction;peeling;transmission

目 录

摘要…………………………………………………………………………………………2

关键词………………………………………………………………………………………2

1前言…………………………………………………………………………………………3

1.1目的意义和国内外现状概况………………………………………………………3

1.2 深加工处理流程……………………………………………………………………3

1.2.1 红薯的分级………………………………………………………………3

1.2.2 红薯的清洗……………………………………………………………4

1.2.3 红薯的去皮………………………………………………………………4

1.2.4 红薯的护色………………………………………………………………4

1.3国内外典型的去皮设备………………………………………………4

1.3.1 机械去皮装置……………………………………………………………5

1.3.2 蒸煮去皮装置……………………………………………………………6

1.3.3 化学去皮装置……………………………………………………………6

2红薯去皮机的结构设计………………………………………………………………7

2.1基本结构…………………………………………………………………………7

2.1.1工作圆筒……………………………………………………………………7

2.1.2工作转盘……………………………………………………………………7

2.1.3传动系统……………………………………………………………………7

2.1.4其他…………………………………………………………………………8

2.2工作原理………………………………………………………………………8

3红薯去皮机的参数确定……………………………………………………………8

3.1 物料在工作圆筒内的受力分析…………………………………………………8

3.2工作转盘转速的确定………………………………………………………………9

3.3红薯去皮机功率的确定………………………………………………………10

3.4整机主要参数指标………………………………………………………………11

4主要零件的结构设计与计算……………………………………………………………12

4.1 V带轮结构设计计算………………………………………………………12

4.2传动主轴的结构设计计算………………………………………………………14

4.2.1轴上零件的周向定位……………………………………………………15

4.2.2确定轴上圆角和倒角尺寸………………………………………………15

4.3滚动轴承的初步选择……………………………………………………15

5主要零件的校核…………………………………………………………………………16

5.1滚动轴承的寿命计算……………………………………………………………17

5.2轴的计算和校核…………………………………………………………………18

6总结………………………………………………………………………………………19

参考文献………………………………………………………………………………20

致谢………………………………………………………………………………………21

附录…………………………………………………………………………………………21

附录

附录1:传动轴

附录2:V带传动轮

附录3:立式轴承座

附录4:装料仓

附录5:机架

附录6:装配图