型砂处理机破碎机构的设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

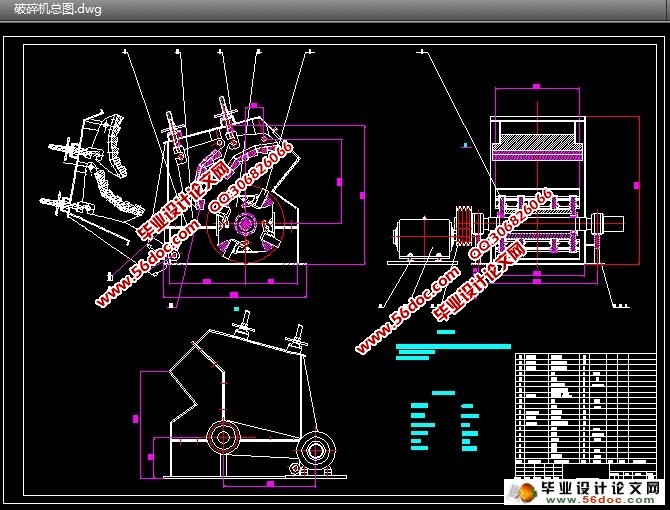

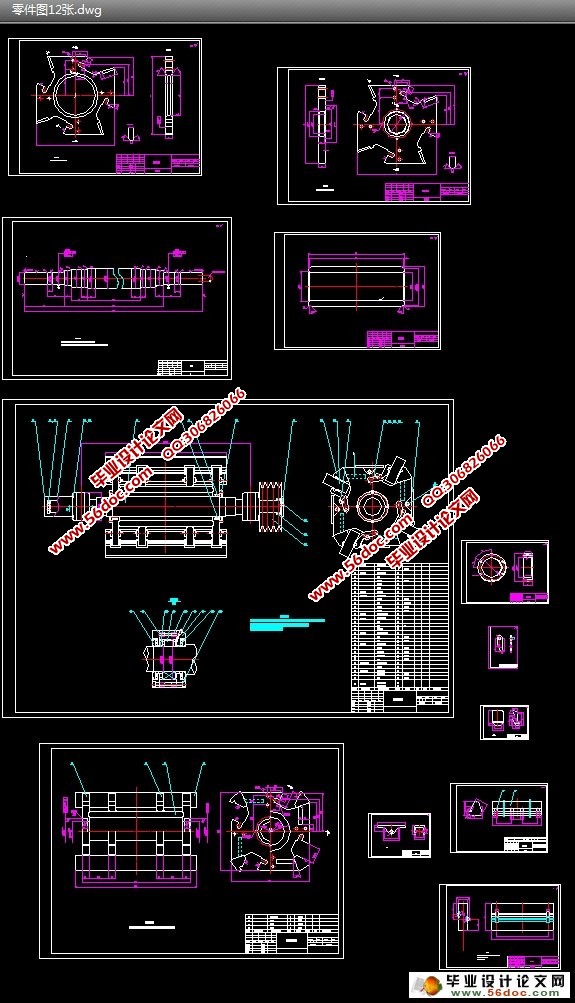

型砂处理机破碎机构的设计(含CAD零件图装配图)(开题报告,中期报告,外文翻译,论文说明书16500字,CAD图13张)

摘 要

本设计为反击式破碎机的设计,主要研究内容:转子的机构设计;板锤的结构设计;板锤的固定方法。

本设计由转子型号入手,初步确定转子的转速,从而确定线速度、板锤大小、数量等相关数据。在保证生产率和破碎粒度的前提下完成总体结构的设计,然后根据总体结构,从而确定本设计的破碎机各个主要零部件的设计。

在主要零部件的设计中,主要包括带轮的设计计算、轴的结构设计、轴承的选择、转子部件的设计计算、板锤的结构和固定、破碎腔的设计等,其中最重要的就是转子部件的设计。转子形状采用铸钢板做成的圆盘叠合而成,板锤采用楔块固定,并使用新型材质以提高其的耐磨性和利用率。

本设计能进一步提高其破碎性能,结构简单、重量轻、外形尺寸小、设备费用低、运转安全、操作方便、便于维修和管理。

关键词:反击式破碎机;研究内容;结构;计算

Sand Processor Crushing Mechanism Design

Abstract

The specification of the design is impact crusher design, the main research contents: the institutional design of the rotor plate hammer; structure design; plate fixation hammer.

The design consists of a reference rotor model, a preliminary determination of the rotor speed, speed, size, number plate hammer and other related data to determine. In ensuring the completion of the overall structure of the design productivity and particle size under the premise, then according to the overall structure, so as to determine the design of crusher to each of the major components of the design.

The design of the main components, including pulley design calculation, structural design of shaft, bearing selection, design and calculation of the rotor components, board structure and a fixed hammer, crushing cavity design, design is the most important part of the rotor. The shape of the rotor adopts cast steel made disc which are laminated plate hammer, the wedge block is fixed, and the use of new materials to improve their wear resistance and utilization.

The design of crushing performance, simple structure, light weight, small size, low cost of equipment, operation safety, convenient operation, easy to repair and management.

KeyWords:Impact Crusher;content;structure;calculation

目 录

1 绪论......................................................................................................................1

1.1 研究的目的与意义.......................................................................................1

1.2 反击式破碎机的特点与发展现状...............................................................2

1.2.1反击式破碎机的特点.......................................................................... 2

1.2.2反击式破碎机的破碎机理...................................................................4

1.2.3反击式破碎机发展现状.......................................................................4

1.3 反击式破碎机主要零部件.............................................................................7

1.3.1反击板...................................................................................................7

1.3.2 调整装置..............................................................................................7

1.3.3 转子......................................................................................................7

2 反击式破碎机总体结构设计.......................................................................8

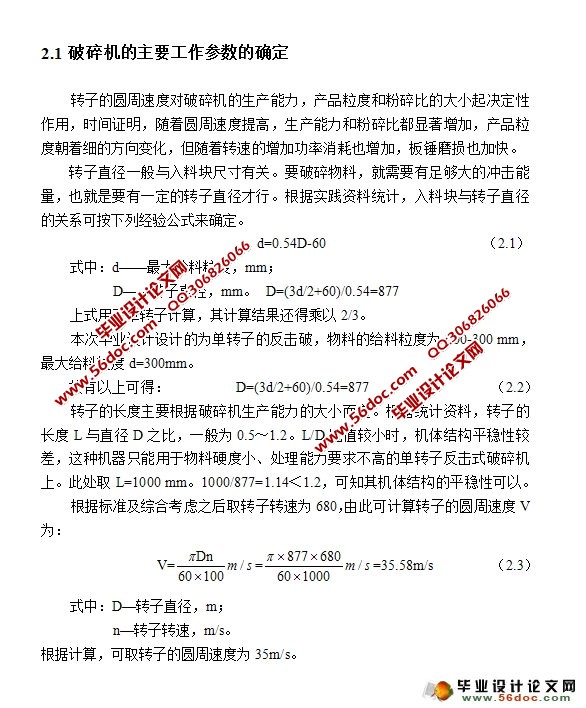

2.1 破碎机的主要工作参数的确定.....................................................................8

2.2 板锤数目和生产率.........................................................................................9

2.3 转子部件的设计计算.....................................................................................9

2.3.1 转子结构设计......................................................................................9

2.3.2 板锤结构设计及作用........................................................................10

2.4 电动机的选择...............................................................................................11

3 传动方案的选择及部件的设计计算.......................................................13

3.1 传动方案的选择...........................................................................................13

3.2 v带及带轮的设计计算.................................................................................14

4 轴的结构设计及轴承的选择.....................................................................17

4.1 轴的结构设计...............................................................................................17

4.2 轴承的选择...................................................................................................18

5 反击式破碎机破碎腔的设计.................................................................... 20

6 转子轴强度计算校核...................................................................................24

7结论.....................................................................................................................27

参考文献................................................................................................................28

致 谢..................................................................................................................29