LU-5型螺旋加料机的设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

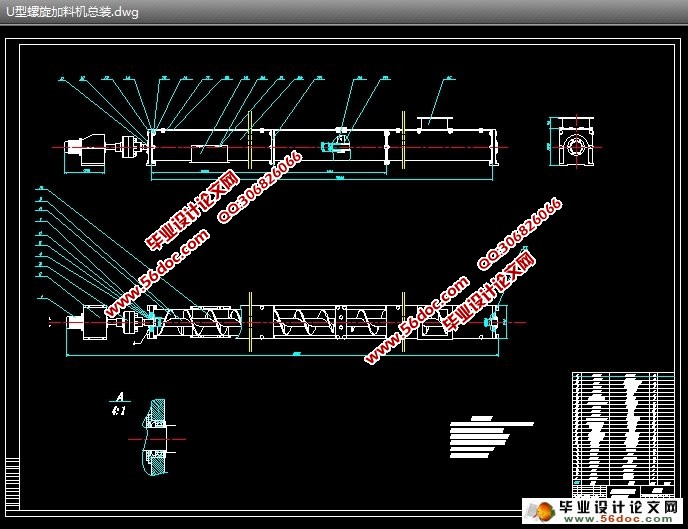

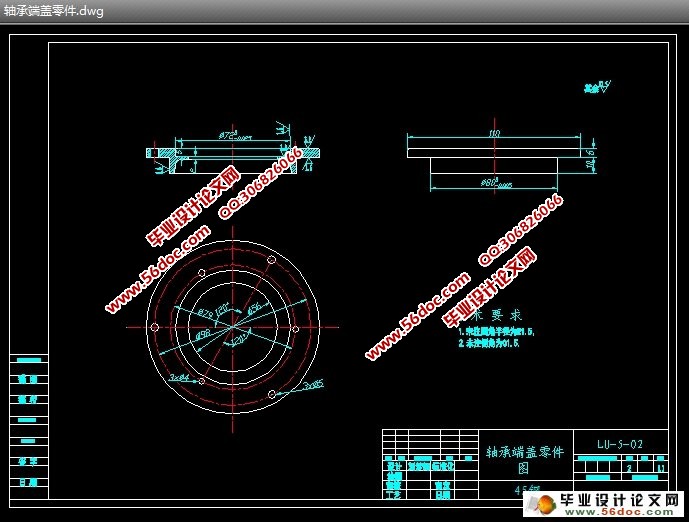

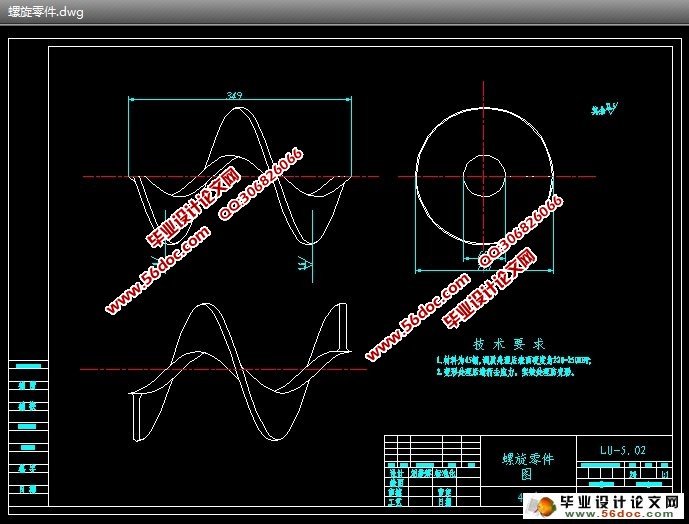

LU-5型螺旋加料机的设计(含CAD零件图装配图)(设计说明书8500字,CAD图18张)

摘 要:本设计在前人研究的基础上针对课题的实际应用在具体环境中进行设计,可实现了饲料的输送和与烘干机的配套使用。首先介绍了螺旋加料机的国内外发展等基本情况,从整体上认识这种机器。然后对机器的主体零件进行参数设计,如计算叶片直径、螺旋轴直径、功率、转矩等参数进行计算,根据计算结果选择电动机、减速器、联轴器,并根据螺旋轴的直径选择轴承。参数确定后对整机结构进行安排、设计,采用了U型壳体分段连接,并根据系统刚度需要设计了吊装轴承。考虑物料可能堵塞轴承,对在轴承端加反向螺旋的分布形式。由于轴的长度为减少自重采用了空心传动轴与实轴连接的方法。

关键词:U型; 螺旋;加料机

THE DESIGN OF LU-5-TYPE SCREW FEEDER

Abstract:In this design,based on previous studies,the subject was designed for the practica environment, It would become true that the scre feeding machine can support the use of dryer. At first,author introduced the basic situation of the screw feeding machine for historical development, and grasped of machine form the whole. Then, introduced how to make sure the main body of the machine parts ,for example, blade diameter, spiral-axis diameter, power, torque and so. According to the calculation results ,The motor, reducer and coupling are choiced.In accordance with diameter of screw shaft ,making sure the bearings. After determining the main parameters of the machine, it is designed of structure. It was piecewise connected by used of U-shell, and stiffness of the system need to use a crane bearing. Be considered that materials may plug in the bearing so used the distribution of plus-end distribution of the form of reverse spiral. Due to the length of axis used the hollow shaft connected with the real axis method to reduce the weight of axis. Finally, a brief introduction in the process of drawing two graphics software applications.

Keywords:U type, Spiral, Feeding machine

本课题设计的螺旋加料机是与饲料加工中的烘干机相配套的,加料机型号为LU-5,壳体为U形,输送能力为5T/h,输送长度为5m,最大输送倾角为30°。现根据要求的参数设计输送机的主体结构尺寸和相关部件的尺寸。

目 录

摘 要 1

关键词 1

1 前言 2

2 绪论 2

2.1 输送机国内外的发展状况及趋势 2

2.2 螺旋输送机简介 3

2.3 课题介绍 4

3 计算 4

3.1 计算螺旋直径 4

3.1.1确定倾角系数 4

3.1.2 确定填充系数 5

3.1.3 确定螺距 5

3.2 验算转速 6

3.3 计算螺旋轴直径 7

3.4 电动机选型 7

4 螺旋输送机的总体机构及主要部件设计 8

4.1 螺旋叶片 8

4.1.1螺旋叶片类型 8

4.1.2 螺旋叶片旋向 9

4.1.3 螺旋输送机总体结构 9

4.2 进出料口设计 10

4.3 螺旋轴的设计、验算 11

4.4 选择减速装置 12

4.5 选择联轴器 12

4.6 选择轴承 13

4.6.1 选择两端支撑轴承 13

4.6.2 设计悬挂轴承 13

4.7 轴承的密封 13

5 螺旋输送机的安装、保养 13

5.1安装 13

5.2 维护 15

参考文献(References) 16

致 谢 17