TGSS-50型刮板传输机的设计

无需注册登录,支付后按照提示操作即可获取该资料.

TGSS-50型刮板传输机的设计(开题报告,外文翻译,毕业论文说明书23000字,CAD图纸9张)

摘要

设计概况

刮板输送机是输送粉尘状、小颗粒及小块等散状物料的连续输送设备,可以水平、倾斜和垂直输送。MS即指水平型输送机,由于输送时,刮板链条全被埋在物料之中,故称为MS埋刮板输送机;又因为埋刮板机槽宽是500mm所以称为MS50型刮板输送机。输送物料具有内擦力和侧压力等特性。垂直输送时,主要依赖物料所具有的起拱特性。封闭机槽内的物料在受到刮板链条在运动方向的推力,且受到下部不断的给料而阻止上物料下滑的阻力时,产生横向阻力时,产生横向侧压力,从而增加物料的内摩擦力,当物料之间的内摩擦力大于物料和侧壁间的外摩擦力及物料自重时,物料就随刮板链条在运动中有振动,有些物料的料拱会时而形成,因而使物料在输送过程中对于链条产生一种滞后现象,影响输送能力。埋刮板输送机主要由封闭断面的壳体(机槽)、刮板链条、驱动装置及张紧装置等部件组成。其设备结构简单、体积小、密封性能好、安装维修比较方便;能多点加料、多点卸料,工艺选型及布置较为灵活;在输送飞扬性、有毒、高温、易燃易爆的物料时,可改善工作条件,减少环境污染。埋刮板输送机目前已被广泛应用于化工、建材、冶金、电力、粮食、轻工和交通领域。MS型埋刮板输送机是采用倾斜度较小或水平布置的一种刮板输送机,其倾角一般为0。≤a≤15。。单台设备的输送高度不大于80m。

关键词: 输送 料拱 内摩擦力 外摩擦力 侧压力

Design overview

Scraper conveyor is conveying dust, small particles and small pieces of etc of continuous conveying equipment, vertical and horizontal, tilt. MS horizontal conveyor, because that means, scraper conveyor chains are buried in the material, so called MS scraper conveyor, And because the wind was buried trigger 500mm therefore called slot width MS50 type scraper conveyor. Materials to be conveyed with force and the lateral pressure inside brush etc. Vertical conveyor, which mainly rely on materials of arch characteristics. Sealing material in the slot machine by scraper chain in the direction of movement, and is constantly under the thrust of the feeding and prevent slipping on the resistance, transverse resistance, transverse lateral pressure, thus increasing the friction material, when materials within the friction between the inside wall of the room than material and the friction and weight materials, materials with scraper chain in movement, some materials are of vibration, thus will sometimes arch in the process of conveying material to produce a lag phenomenon chain, transmission capacity. Scraper conveyor consists mainly of closed cross-section of the shell (machine), scraper chain, driving device and a device etc. Parts. The equipment is simple in structure, small volume, sealed performance is good, easy installation and maintenance, Can more charging and discharging points, process selection and arrangement more flexible, The dust, poisonous, high temperature, inflammable and explosive materials, can improve the working conditions, and reduce environmental pollution. Scraper conveyor has been widely used in chemical industry, building materials, metallurgy, electric power, food, light industry and transportation. MS type scraper conveyor is smaller or using gradient layout of a level of scraper coveyor, its Angle is commonly 0. More than a more than 15. The single machine conveyance height is not more than 80m.

Keywords: transport within the friction friction material arch lateral pressure

本课题拟通过设计一个型号的水平输送刮板机,完成机头部分的的设计和计算; 学习如何综合应用本专业的知识进行资料的查阅、方案的拟定和设备的具体设计,熟悉机械图样的绘制方法,熟练掌握计算机绘图的技能。通过此次设计,提高分析问题、解决问题的能力,培养认真、踏实、严谨的工作作风。

主要的设计内容:

设计TGSS-50型水平刮板输送机,设计产量220~300(t/h)(处理原料为破碎大豆),完成整体结构、传动装置、筒体部装、底座装置等零部件的设计、绘图,图纸采用计算机绘图和手绘来完成。

目录

1.绪论 1

2.TGSS-50型水平刮板输送机应用、组成、原理特点 4

2.1主要类型和应用范围 4

2.2 主要组成部分 5

2.3 工作原理 9

2.4主要特点 10

3.本课题的设计目的和主要内容 11

4.设计计算 12

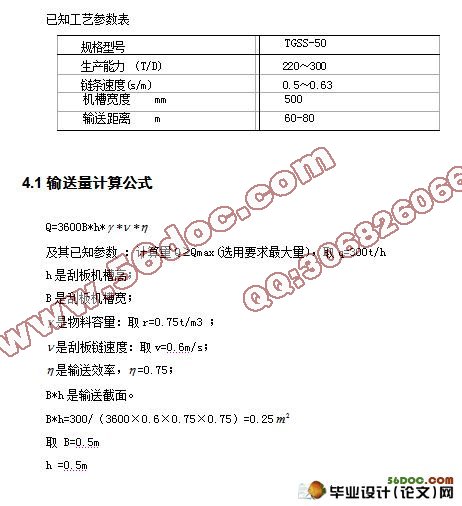

4.1输送量计算公式 12

4.2刮板链条张力计算 13

4.3电动机的功率计算 14

4.4输送链的选择与设计 15

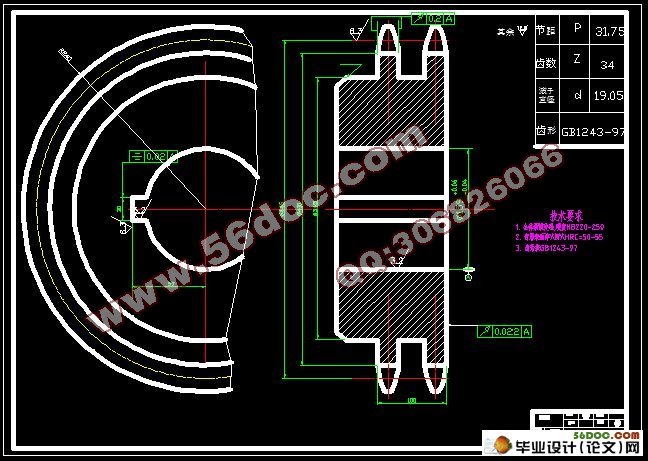

4.5链轮设计 19

4.6减速器计算选型 21

4.7齿轮的设计 22

4.7.1 高速级齿轮的设计 22

4.7.2 低速级齿轮的设计 27

4.8轴的设计与校核 32

4.9联轴器选择计算 36

5.轴承的选择与计算 37

5.1轴承的选择 37

5.2轴承的润滑与密封 37

5.3键的设计和计算 38

6. 设备安装 40

6.1 安装前的准备工作 40

6.2 地面试装的要求 40

6.3 安装程序 41

6.4 安装方法及注意事项 42

7.正确调试方法 43

7.1 紧链方法 43

7.2 试运转 43

7.3 空载运转注意事项 44

7.4 与配套设备联合运转注意事项 44

8.机器的安全操作 45

8.1 操作前的准备与检查 45

8.2 操作一般步骤 46

8.3 操作安全注意事项 47

8.4 操作规程的具体要求 47

8.5 司机的岗位安全责任制 48

9.维护与检修 50

9.1 日常维护 50

9.2 月检 51

9.3 中修 52

9.4 大修 52

10.常见的机械故障及排除 53

10.1 断链 53

10.2 减速器声音不正常 55

10.3刮板链跳牙 55

10.4 刮板弯曲和折断 56

小 结 57

致 谢 59

参考文献 61