图书馆AGV小车取料增速机构设计(含CAD图纸,CAXA图)

无需注册登录,支付后按照提示操作即可获取该资料.

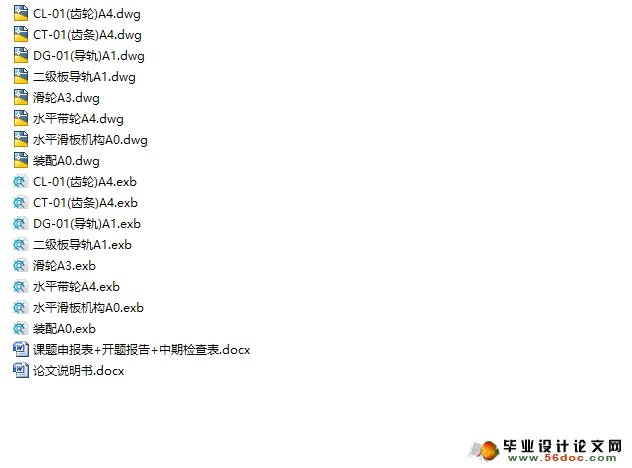

图书馆AGV小车取料增速机构设计(含CAD图纸,CAXA图)(课题申报表,任务书,开题报告,中期检查表,论文说明书10000字,CAD图纸8张,CAXA图纸8张)

摘要

随着工厂计算机集成制造技术与自动化的不断发展以及柔性制造系统、自动化仓库的大量使用,AGV(Automatic Guided Vehicle)即自动导引车是联系和调节离散型物流系统能够使其作业连续化的自动搬运装卸手段,其使用范围和技术水平取得了快速的发展。

AGV是一个单片机为控制核心,由电池供电,配备非接触式导引装置的无人自动导引卡车设备,作业的基本功能是自动导向行驶,确定准停和负载的转移。关键设备和柔性制造系统作为当代物流处理自动化系统的有效手段,AGV已经被越来越广泛的应用,对AGV的研究也具有重要的理论意义和现实意义。

本文介绍了AGV在国内外的发展现状和应用情况,在此基础上,结合毕业设计的课题要求,设计了图书馆AGV小车。

关键词:AGV;搬运;自动化

ABSTRACT

As factory automation technology, computer integrated manufacturing system of gradual development and wide application of flexible manufacturing system, automated stereoscopic warehouse, AGV (Automatic Guided Vehicle) automatically DaoYinChe as contact and regulating discrete logistics system in order to make the operation of continuous necessary means of transportation and handling automation, its application scope and the technical level obtained the swift and violent development.

AGV based on microcontroller as the control core, battery power, is equipped with non-contact comprise unmanned homing guidance device, is the basic function of the automatic operation guide and quasi recognition site shutdown and over load. As effective means of logistics process automation and the key equipment of the flexible manufacturing system, AGV has received more and more extensive application, the research of AGV also has very important theoretical significance and practical significance.

This paper introduces the AGV in the domestic and foreign development present situation and the application situation, on this basis, combined with the graduation design task requirement, design the library AGV car.

Keywords: AGV; Handling; automation

目录

摘要 I

ABSTRACT II

1 绪论 1

1.1 AGV小车发展现状研究 1

1.1.1国外研究状况 1

1.1.2 国内发展情况 2

1.1.3 AGV在中国应用的新趋势 3

1.1.4 AGV的应用 4

1.2 AGV系统的构成与AGV的结构 6

1.2.1 AGV系统的构成 6

1.2.2 AGV的结构 7

1.3 AGV导航系统 9

1.3.1固定路线方式 9

1.4图书馆AGV小车发展 10

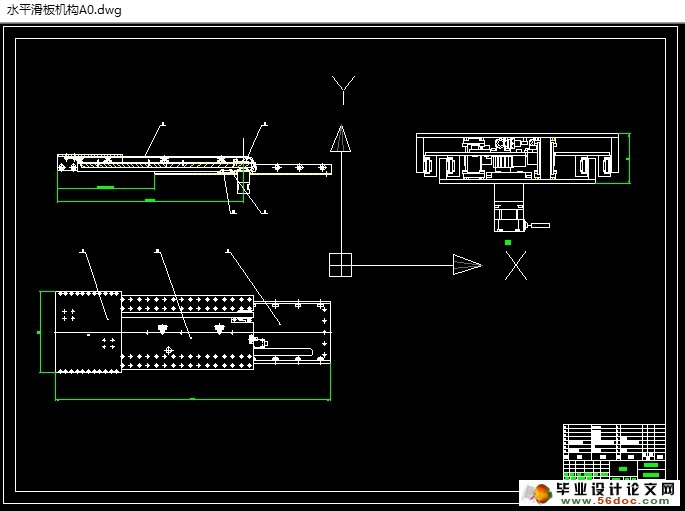

2图书馆AGV取料增速机构设计与原理分析 11

2.1小车取料增速机构设计与原理分析 11

2.1.1增速机构整体方案的设计 11

2.1.2 增速机构输入和输出连接装置的选择 12

2.1.3增速机构总体设计 12

2.2小车取料增速机构零件选型 19

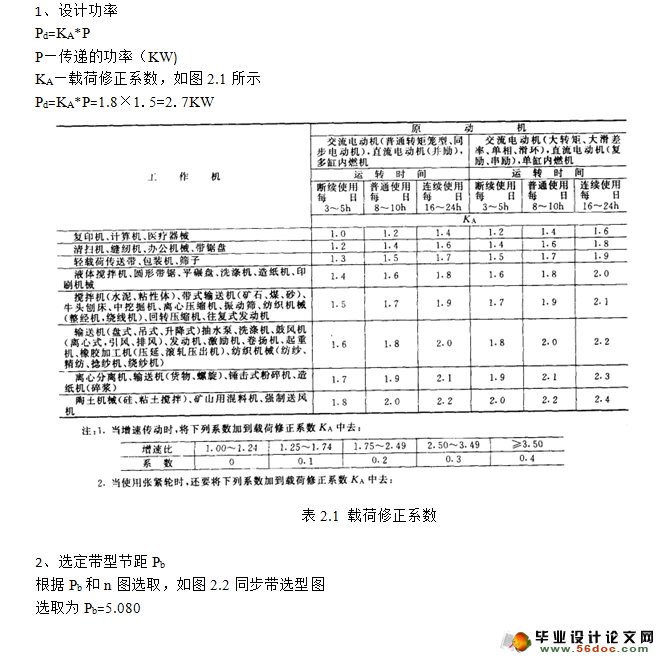

3图书馆AGV小车取料增速机构设计计算 20

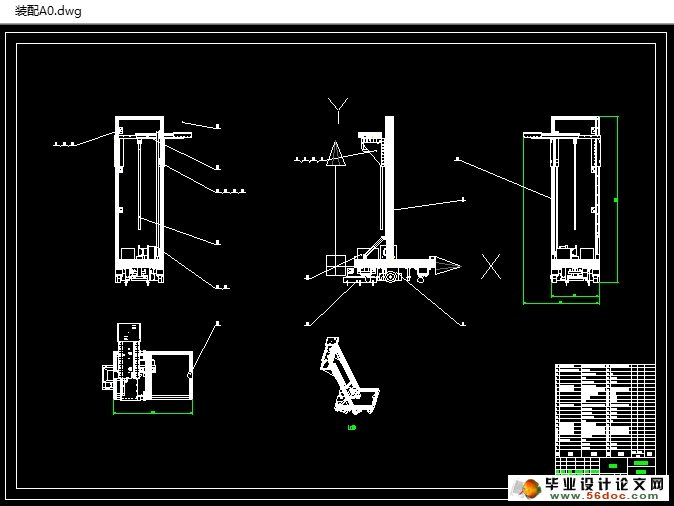

4工程图设计 24

4.1装配图设计 24

4.2零件图设计 24

结论 25

致谢 26

参考文献 27