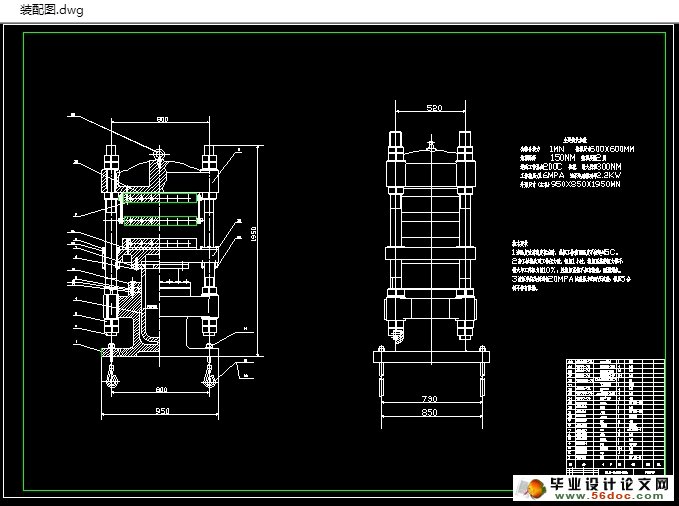

柱式平板硫化机主机设计(QLB-600×600)(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

柱式平板硫化机主机设计(QLB-600×600)(含CAD零件装配图)(任务书,文献综述,论文说明书14500字,CAD图纸3张)

摘要

将没有硫化的半成品装入模型后,该模型被放置在两个热板之间的间隙,(无模型制品如胶带,塑料片的热板之间直接放置)。然后通过液压介质(油或水)的液压缸,然后推动柱塞移动平台和所述热板的向上或向下运动,推动可动模具夹紧板或制品。在硫化后进行移动的同时进入加热板通过加热介质,使模型(或产品),以获得固化过程所需的压力和温度,在一段时间(固化时间)后完成后,则液压缸液压介质排除在外,由于柱塞在本身自重(或双作用缸的液压)作用下下降,便可取出制品。

当硫化机工作热板加热,使橡胶和橡胶分子发生了交联,其结构由线型结构变成网状的体形结构,这是可获得具有一定物理机械性能的制品,但胶料受热后,软化了结构,同时胶料内的水份及易挥发的物质要气化,然后依靠液压缸给予足够的压力,以橡胶完整模型,并限制气泡,制品结构致密原因的形成。如果是胶布层制品,塑料和布可以牢牢地粘在一起。此外,给予足够的压力,以防止从接缝面模具出现溢边,图案缺胶,气孔海绵等。

有柱塞、液压缸、动平台、桌垫、热板和装配图的主要部分的量的设计。

关键词: 平板硫化机; 原理; 主要零件; 工作过程

Abstract

After uncured semi-finished products into the model, which is placed in the gap between two hot plates, (no model products as placed directly between the tape and plastic sheets hot plate). Then by a hydraulic medium (oil or water) of the cylinder, then push the plunger to move the platform and the hot plate upward or downward movement, pushing the movable mold clamping plate or products. At the same time move after vulcanization by heating medium into the heating plate, so that the model (or product), to obtain the desired pressure and temperature of the curing process, after a period of time after the completion of (curing time), the pressure medium cylinder excluded Since the plunger in itself fall under its own weight (or double-acting hydraulic cylinders) role, you can remove the products.

When working hot plate heated vulcanizing machine, rubber and rubber molecules cross-linked, its structure from a linear structure into a mesh shape structure, which is the product obtained with certain physical and mechanical properties, but the plastic material is heated, soften the structure, while the water inside the compound and volatile substances to be gasified, and then rely on the hydraulic cylinder give enough pressure to rubber full model, and limit bubble formation causes of product structure compact. If the tape layer, plastic and cloth can be glued together firmly. In addition, given enough pressure to prevent mold from the joint surface overflow edge, pattern lack of plastic, porosity sponges.

Plunger、the amount of the main part of the design of the hydraulic cylinder、 moving platforms、hand bags、hot plate and assembly drawings.

Keywords: vulcanizing press; principles; main parts; work process

目 录

第一章简介 1

1.1 平板硫化机的简介 1

1.2 优点参数 1

1.3 作用 2

1.4 设备功能 3

1.5 机型特点 3

1.6 工作原理 4

第二章硫化机的保养和维护 5

2.1 分类 5

2.3 安全操作 7

2.4 注意事项 8

2.5 零部件 8

第三章主要零部件设计 12

3.1 柱塞 12

3.1.1 柱塞的选材 12

3.1.2 结构尺寸及强度计算 12

3.2 工作缸 13

3.2.1 结构形式 14

3.2.2 材料 14

3.2.3 结构尺寸 14

3.3 密封装置 16

3.3.1 对密封装置的要求 16

3.3.2 密封件 17

3.3.3 法兰 18

3.4 立柱与螺母 21

3.4.1 立柱 21

3.4.3 立柱计算 21

3.4.4 螺母 23

3.5 热板 23

3.5.1 结构与材料 23

3.5.2 电加热元件 23

3.6 活动平台 24

3.6.1 结构 24

3.6.2 材料 24

3.6.3平台负载和力矩负荷力的条件 24

3.6.4 强度校核 25

3.7 上横梁 28

3.7.1 材料 28

3.7.2 受力分析 28

3.7.3 弯矩及弯曲应力 29

3.8 底座 32

3.8.1 结构及尺寸 32

3.8.2 材料 32

3.8.3 受力分析 32

3.8.4 强度校核 36

结论 39

参考文献 40

致谢 41