瓶盖自动封装系统的设计(含CAD零件装配图,SolidWorks三维造型)

无需注册登录,支付后按照提示操作即可获取该资料.

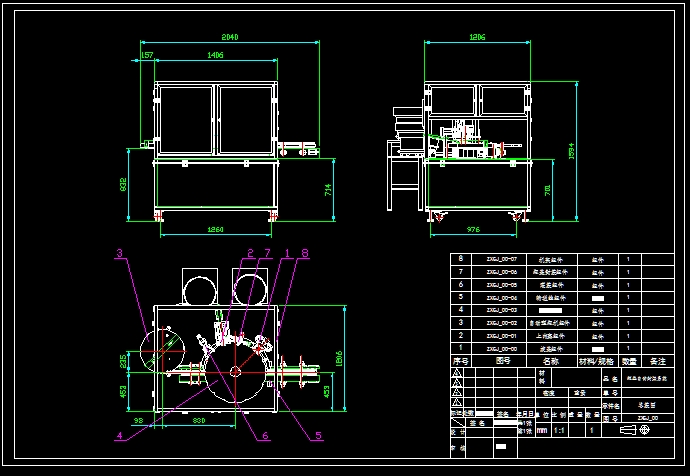

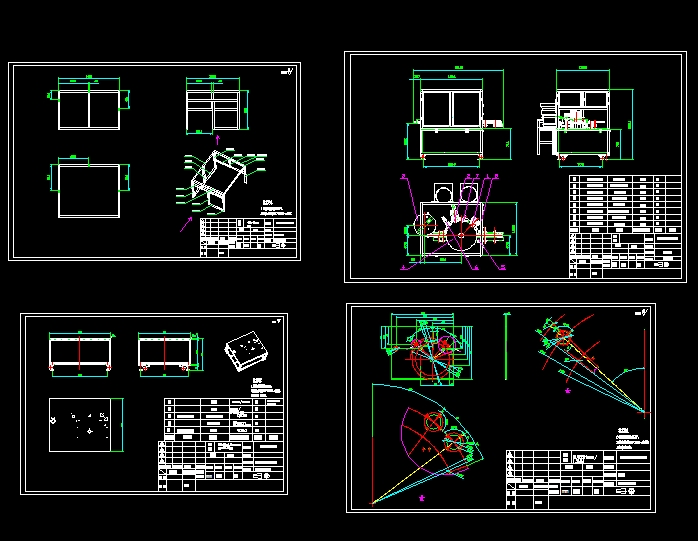

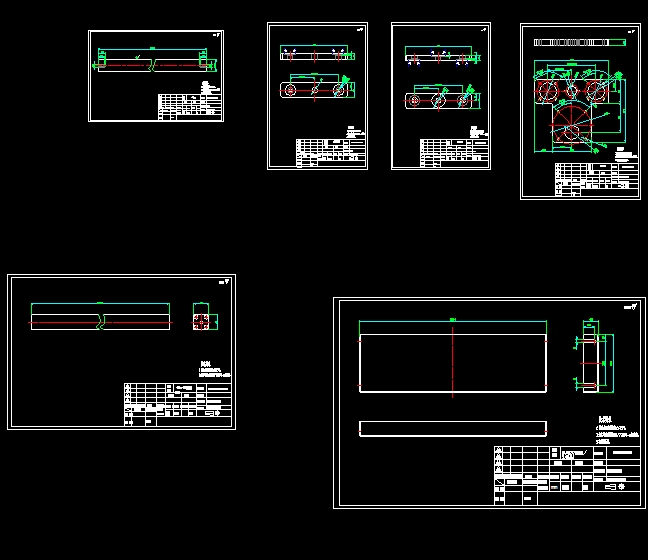

瓶盖自动封装系统的设计(含CAD零件装配图,SolidWorks三维造型)(论文说明书7200字,CAD图纸10张,SolidWorks三维图)

The design of the automatic packaging system of bottle cap

摘要

瓶盖自动封装系统属于包装机械的一种,在现代机械工业如此发达的情况下,该系统也在不断创新和发展着。在全球经济发展的大环境下,中国各个行业被其他国家的先进技术影响的同时,越来越多的外国企业和品牌传播到中国已经成为现实。在新的市场需求的推动下,对瓶盖自动封装系统进行改良和优化是当务之急。有大型生产瓶盖自动封装系统企业对设备的安全指标的有着一定生产的严格要求。在生产设备的企业,充分考虑到在设备运行中可能出现的问题,从而减少噪声污染引起的振动或不当操作设备的现象等。国内瓶盖自动封装系统设备的研发及制造要与全球号召的高效经济、安全稳定主题保持一致。瓶盖自动封装系统的发展与人类社会的进步和科学技术的水平密切相关。

本次的设计就是瓶盖自动封装系统的设计,通过对瓶盖自动封装系统进行结构设计,以及其中的标准件进行选型设计,大大提高了它的稳定性。相信此次设计的瓶盖自动封装系统的出现将会大大提高传统的瓶盖自动封装系统的自动化程度和质量,为包装机械工业的发展以及人民生活水平的提高能够带来显著的进步,同时也在某种程度上推进了机械工业的不断发展。

关键词:包装机械;瓶盖自动封装系统;工业;发展

Abstract

Automatic filling of the gland joint machine design include: Pull out the gear devices into the bottle, the bottle Pull out the gear devices limit screw device; In this paper, a bottle of brandy round of star-shaped, spiral spacing, and steeplechase bottle into the structure, design and calculation, and to understand the commissioning and maintenance of equipment. Dial star-shaped bottle filling machine round is to limit the agency sent the bottle, filling machine accurately into the take-off and landing or a bottle filled with the bodies removed from the lift conveyor belt into the body. Quantitative liquid materials into the packaging container filling machine filling machinery called. Because the number to be filled with liquid with liquid,Therefore, the general container used for rigid containers, such as bottles, glass bottles , metal cans, cartons and other composites. Conveyor belt, sub-items for delivery screw, star-shaped and arc-shaped guide plate pull out the gear combination for the importation of container.

Pull out the gear At the same time, the output is also used in containers. Spiral limit in the field of packaging industry, is now widely applied to various types of sub-items for delivery screw device, a process may require rules or irregular array of containers, objects to determine the speed, direction and distance individually or in batches to a given position. The design is mainly used to separate sub-items for delivery are typical combination of cylindrical device, the sub-items for delivery.

Keywords:Driving roller ;Crankshaft;Processing; craft

同步带传动的设计计算

(1)传动名义功率P_=0.5kW

(2)主动轮转速n1=1500r/min,从动轮 =350r/min

(3)中心距a=100mm左右

(4)工作情况, 24小时运转.

求设计功率P=K0 Pm=0.4×2= 0.8Kw,式中Ko为载荷修正系数

由设计功率0.8Kw 和n =1500r/min,由查得带的型号为L型,对应节距P =9.525mm

目 录

摘要 I

Abstract II

1引言 1

1.1 课题的来源与研究的目的和意义 1

1.2 包装机械的发展现状 2

1.3 本课题研究的内容 3

2瓶盖自动封装系统总体结构的设计 6

2.1 机械传动部分的设计计算 7

2.1.1 同步带传动的设计计算 8

2.1.2 瓶盖封装电机的选型计算 9

2.1.3 V带传动的校核计算 10

2.1.4 轴的设计计算 11

2.1.5 光电传感器的选型 12

3 瓶盖自动封装系统中主要零部件的强度校核 14

3.1 传动轴的强度校核计算 15

3.2 螺栓强度的校核计算 17

4瓶盖自动封装系统中主要零件的三维建模 18

4.1输送线的三维建模 19

4.2瓶盖封装电机的三维建模 20

4.3转盘的三维建模 22

4.4瓶盖自动封装系统的三维建模 23

5三维软件设计总结 24

结论 25

致谢 26

参考文献 27