自动洗衣机行星齿轮减速器(含CAD零件装配图,SolidWorks三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

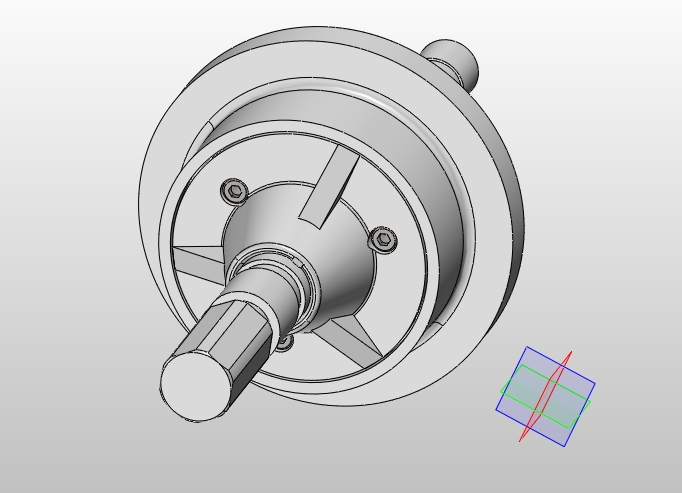

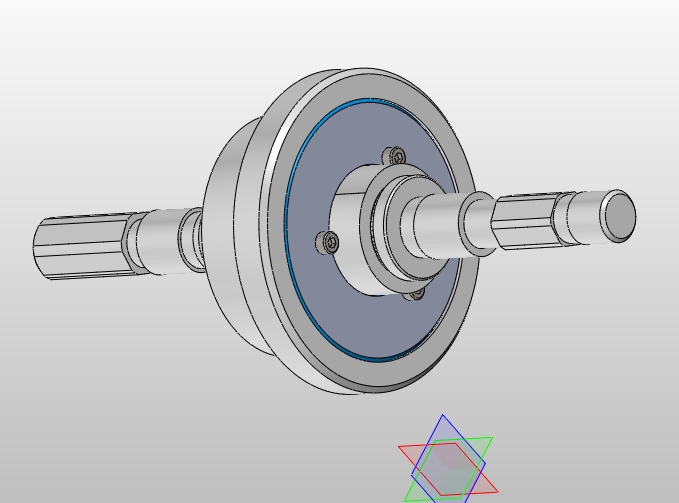

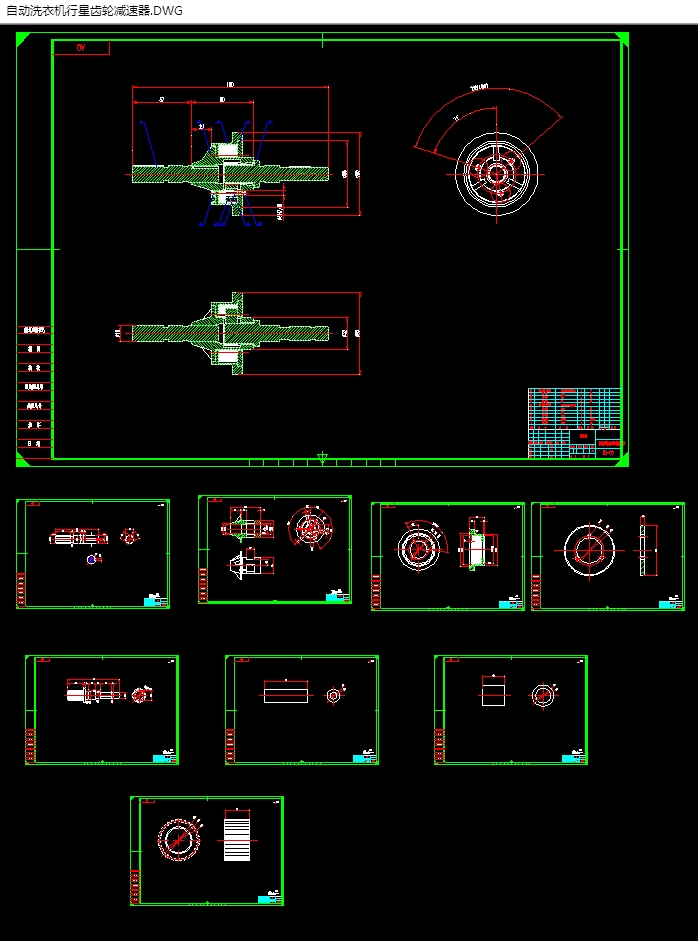

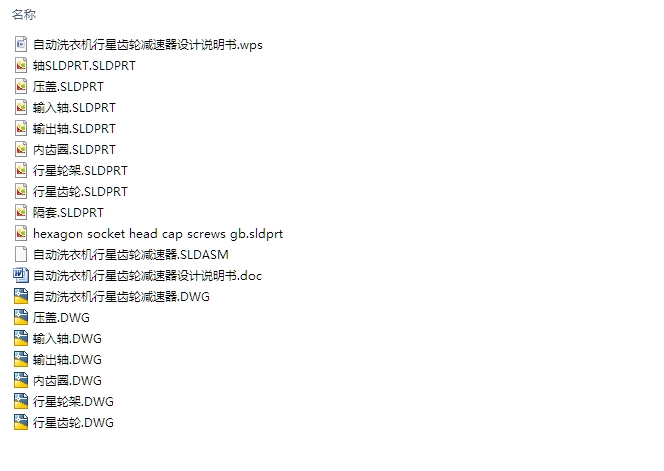

自动洗衣机行星齿轮减速器(含CAD零件装配图,SolidWorks三维图)(论文说明书8800字,CAD图纸9张,SolidWorks三维图)

摘要

随着国民经济的持续发展,机械工业也在不断地发展着,各种设备都在不断地发展,创新着。特别是在家用电器方面,在人们的居家生活中,自动洗衣机的的应用非常广泛,特别是行星减速器内置式的全自动洗衣机,在某种程度上,因为行星齿轮减速器占地面积小,变速灵活,价格成本低廉而很受欢迎,根据市场调查发现,行星齿轮减速器必须满足当今人们对自动洗衣机速度调节方面的灵活性操控等需求。

本文介绍了自动洗衣机行星齿轮减速器的结构组成、工作原理以及主要零部件的设计中所必须的理论计算和相关强度校验,以及对其结构进行创新设计,该减速器的优点是结构紧凑、传动效率高、外廓尺寸小和重量轻、承载能力大、运动平稳、抗冲击和震动的能力较强、噪声低的特点。

关键词:机械工业;自动洗衣机;行星;平稳

Abstract

With the continuous development of the national economy, the machinery industry is constantly developing, all kinds of equipment are in constant development, innovation. Especially in household appliances, in people 's home life, and application of the automatic washing machine is widely, especially planetary reducer is a built-in type full automatic washing machine, in a way, because the planetary gear reducer has the advantages of small occupation area, flexible speed, cost is low and very popular, according to the market survey found, planetary gear reducer must meet the needs of today's people of automatic washing machine speed regulation flexibility control demand.

This paper introduces the automatic washing machine planet gear deceleration device, the structure of the composition, working principle and main parts design must have the theoretic calculation and strength check, and to carry out innovative design of the structure, the unit has the advantages of deceleration is of compact structure, high transmission efficiency, outline, small size and light weight, bearing capacity, smooth movement, impact and shock resistance ability, low noise characteristics.

Key words: mechanical industry; automatic washing machine; planet; smooth

目录

第一章 绪论 1

1.1课题的来源及研究的目的和意义 1

1.2本课题研究的主要内容 2

第二章 齿轮传动的特点 4

2.1齿轮传动的两大类型 6

2.2行星机构的类型及特点 7

第三章 齿轮的设计计算 8

3.1 配齿计算 9

3.1.1 确定各齿轮的齿数 10

3.1.2 初算中心距和模数 11

3.2 几何尺寸计算 13

第四章 轴的设计计算 14

4.1 行星轴设计 15

4.2 转轴的设计 16

4.2.1 输入轴设计 17

4.2.2 输出轴设计 19

第五章 行星架的设计 20

5.1 行星架结构方案 21

5.2 行星架制造精度 21

第六章 减速器内部主要传动零件的强度校核 22

6.1 传动轴的强度校核 23

6.2 传动齿轮的强度校核 24

结论 25

参考文献 26

致谢 27