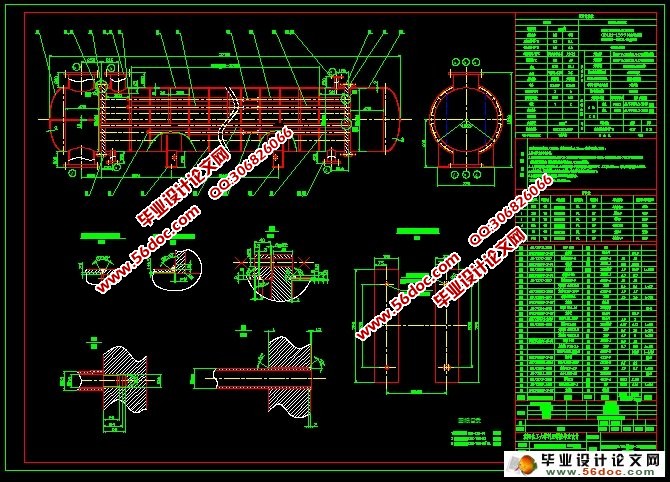

甲胺装置E-751塔冷凝器的设计(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

甲胺装置E-751塔冷凝器的设计(含CAD零件装配图)(设计说明书14000字,CAD图纸9张)

摘要

本设计是双管程固定管板式换热器,是目前应用较为广泛的换热器。固定管板式换热器的优点是:结构简单、紧凑,能承受较高的压力,造价低,管程清洗方便,管子损坏时易于堵管或更换;这种换热器使用于壳侧介质清洁且不宜结垢,并能进行清洗管束,壳程两侧温差不大或者温差较大但壳侧压力不高的场合。

本台换热器主要完成的是甲醇蒸汽、水蒸气-水之间的热量交换,设计压力为管程0.6MPa,壳程0.6MPa,工作温度管程进/出口32/42℃,壳程进出口91.86/86.4℃,设计温度管程60℃,壳程150℃,管程介质为0.4MPa的水,壳程介质主要为0.1MPa的甲醇蒸汽(85%)与水蒸气(15%)的混合物,传热面积为158m2,采用Φ25×2.5×4500的无缝钢管换热,则可计算出446根换热管,DN=800mm的圆筒。本台换热器的管板延长兼做法兰,管板与换热管的连接方式为焊接,因管板上的应力较多,且内外温度有一定的差值,因此,对管板强度的校核是一个重点,也是一个难点,本文按照弹性支撑假设对管板进行设计和校核的。

关键词: 换热管; 固定管板; 温差应力

Abstract

This design is about fixed plate heat exchanges. At present this exchanges are most used.

The advantages of the fixed tube-shell exchanged: The exchanged can bear high press; the price of making is low; Structure is simple and compacted; we can wash the tubes easily; we can change the broken tubes conveniently. The foremost shortcoming of the fixed tube-shell exchanged is the heats tress between the shell and the tubes is very large.

This exchanged is mainly completed the heat exchange from hot water steam to water. The design pressure of the tube-side is 0.6MPa. The design pressure of the shell-side is 0.6MPa. The work temperature of the import and export of the tube-side is 32/42℃.The work temperature of the import and export of the shell-side is 91.86/86.4℃. The design temperature of the tube-side is 60℃.The design temperature of the shell-side is 150℃.The fluid of the tube-side is 0.4MPa water and the fluid of the shell-side is 0.1MPa methyl alcohol(85%)steam and water steam(15%). The area for exchanging heat is 158㎡.The heat exchanged used the tube Φ25×2.5×4500.We can work that this is heat exchanged consist of 446tubes and the DN of shell is 800mm.We weld the tube to the plate because there has a stress between the tube-side and shell-side that is really difficult to work out. The tube plate is designed and checked based in elastic supporting assumption.

Keywords: heat exchange tube; fixed tube sheet; thermal stress

目 录

第一章换热器综述 1

1.1 换热器的概述 1

1.2 管壳式换热器的分类 1

1.2.1 固定管板式换热器 1

1.2.2 浮头式换热器 2

1.2.3 U形管换热器 2

1.2.4 填料函式换热器 2

1.3 换热器设计方案的原则 3

1.3.1 满足工艺和操作的要求 3

1.3.2 满足经济上的要求 3

1.3.3 保证安全生产 3

1.4 换热器管结垢及除垢 3

1.4.1 手工或机械方法 4

1.4.2 冲洗法 4

1.4.3 化学除垢 4

1.5 换热器泄漏后如何进行试漏检查及堵管 4

1.5.1 试漏检查 4

1.5.2堵管 4

1.6 换热器腐蚀的主要部位及腐蚀原因 5

1.6.1 换热器腐蚀的主要部位 5

1.6.2 腐蚀原因如下 5

1.7 换热器的发展前景 5

第二章换热器传热工艺计算 7

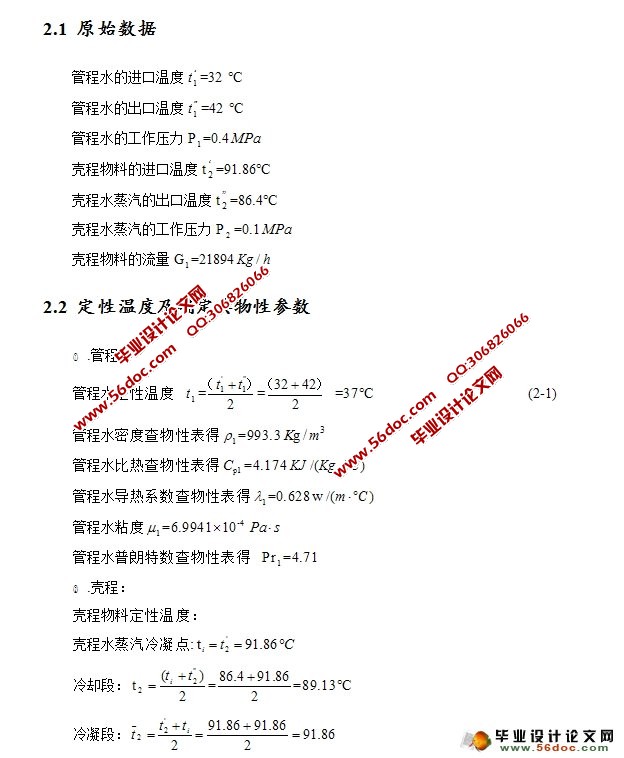

2.1 原始数据 7

2.2 定性温度及确定其物性参数 7

2.3 传热量与水流量计算 8

2.4 有效平均温差计算 9

2.5 管程换热系数计算 10

2.6 结构的初步设计 11

2.7 壳程换热系数计算 11

2.8 传热系数计算 13

2.9 管壁温度计算 13

2.10 管程压力降计算 14

2.11 壳程压力降计算 15

第三章固定管板式换热器结构设计计算 17

3.1 换热管材料及规格的选择和根数的确定 17

3.2 布管方式的选择 17

3.3 筒体内径的确定 18

3.4 筒体壁厚的确定 18

3.5 管箱短节壁厚的计算 19

3.6 筒体水压试验 20

3.7 封头厚度的确定 20

3.8 管箱水压试验 20

3.9 容器法兰的选择 21

3.10 管板尺寸的确定及强度计算 21

3.11 是否安装膨胀节的判定 33

3.12 防冲板尺寸的确定 33

3.13 折流板尺寸的确定 34

3.14 各管孔接管及其法兰的选择 34

3.15 开孔补强计算 38

3.16 鞍座 择及应力校核 41

总结 44

参考文献 45

致 谢 46