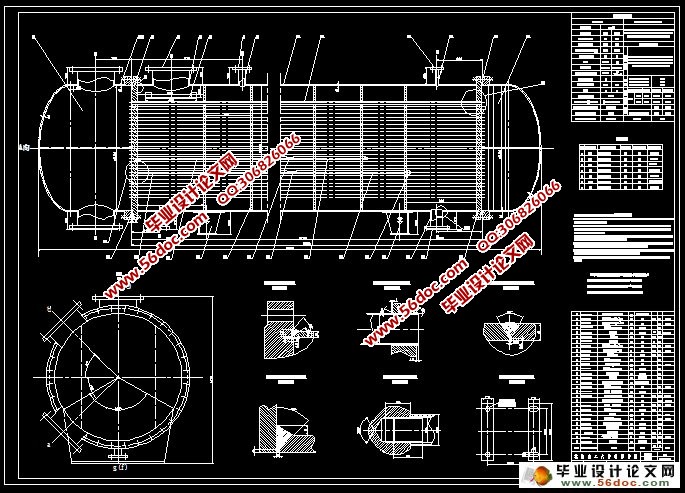

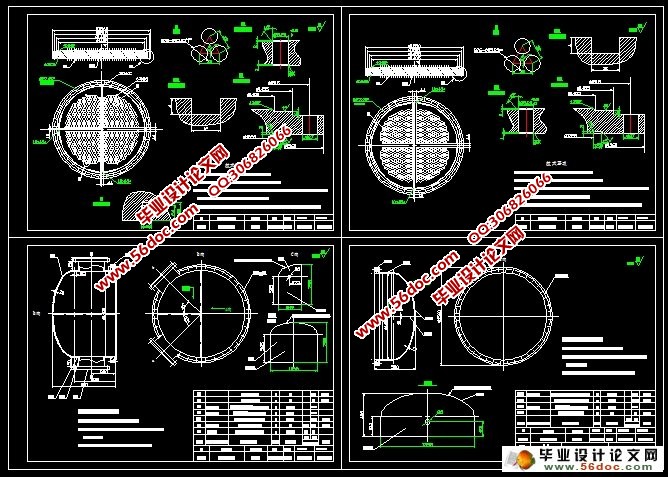

二甲胺换热器设计(流量2500kg/h)(含CAD零件装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

二甲胺换热器设计(流量2500kg/h)(含CAD零件装配图)(设计说明书17600字,CAD图纸11张)

摘要

换热器又被叫热量交换器,是一种进行冷热流体之间的热量传送的设备,它是完成化工等生产过程中交换热量必须用到的设备,在工厂中意义非凡。换热器可以是一种独立的设备,例如加热器、冷却器和凝汽器等等。换热器是两种温度不同的物料在一个设备内相互交换热量,最终达到将物料冷却,或者将冷物料加热为目的的设备。换热器是化工生产中最最常用的一种机器,它的主要作用是进行几种介质之间的热量传递。常见的换热器有:浮头式换热器、固定管板式换热器、填料函式换热器、U型管式换热器、蛇管式换热器、双壳程换热器、单套管换热器、多套管换热器、外导流筒换热器、折流杆式换热器、热管式换热器、插管式换热器、滑动管板式换热器等[1]。本换热器是蒸汽换热器在成产中是非常常见的设备,该换热器有耐高压的优点、价格低廉、清洗方便不宜结垢的优点。

设计任务说明书中所给定的条件是壳程介质为二甲胺,温度从一开始的49.96℃、0.9MPa进行冷凝冷凝,它的流量是2500kg/h。管程中的介质是水,冷却水温度从一开始的33℃升高到了43℃、压力保持在0.6MPa。完成了压降计算、强度计算、开孔补强、管箱短节壁厚计算等。在强度设计中,依据 进行筒体、封头强度设计及校核,依据流量进行入口接管、出口接管等管口直径的选择,依据等面积补强法进行开口补强计算。本设计选择管板延长兼做法兰,依据 中的弹性支撑假设对管板进行设计和校核,管板与换热管的连接方式为焊接,拉杆与管板为螺纹连接结构。同时,进行了卧式容器鞍座校核。

本设计充分的利用材料,适用比较多的场合。在同样的换热器中此换热器十分的廉价、安全。所以该换热器在工厂中占有重要位置。

关键字: 固定管板; 换热器; 不同物料;热交换; 补强

Abstract

Heat exchanger called heat exchanger again, it is a kind of cold and hot fluid between the heat transfer equipment, it is a complete exchange of heat must be used in the process of chemical production equipment, the special significance in the factory. Heat exchanger can be an independent device, such as a heater, cooler and steam condenser and so on. Temperature heat exchanger are two different materials in a heat exchanging equipment, eventually achieve the material cooling, or heating equipment for the purpose of cold material. Heat exchanger is by far the most commonly used in the chemical production of a machine, its main function is to heat transfer between several kinds of media. Common heat exchanger are: of floating head heat exchanger, the fixed tube plate heat exchanger, the stuffing box type heat exchanger, u-shaped tube heat exchanger, coil heat exchanger, single and double shell side heat exchanger tube heat exchanger and tube heat exchanger and diversion tube heat exchanger, rod baffle heat exchanger, heat pipe heat exchanger, heat exchanger intubation, sliding tube plate heat exchanger, etc[1]. This heat exchanger is steam condenser is very common in into during equipment, the heat exchanger has the advantages of resistance to high pressure, low cost, convenient cleaning is unfavorable and scale advantages.

Design task description in the shell side of the given conditions is medium of dimethylamine, temperature of 49.96 ℃, 0.9 MPa from the beginning to condensation condensation, its flow is 1500 kg/h. Tube side of the medium is water, cooling water temperature rose from the very beginning of 33 ℃ 43 ℃, pressure in a 0.6 MPa. Completed the pressure drop calculation, strength calculation, opening reinforcement, short tube box section wall thickness calculation, etc. In strength design, strength design basis for cylinder, head and checking, according to the inlet connection of traffic and exports over the selection of nozzle diameter, opening reinforcement method on the basis of equal area reinforcement calculation. The design of flange, tubesheet extended and do according to the hypothesis of elastic support for tube plate design and checking, tube plate and the heat exchange tube connections for welding, rod and tube plate to the threaded connection structure. At the same time, for the horizontal vessel saddle checking.

This design make full use of material, is more occasions. At the same heat exchanger in the heat exchanger is very cheap and safe. So the heat exchanger occupies an important position in the factory.

Key words: Fixed tube sheet; Heat exchanger; Different materials; reinforcing

目 录

第一章 固定管板式换热器设计方案的选择 1

1.1换热器类型的选定 1

1.2换热器换热方式的选择 2

1.3流体进出口温度的确定 3

1.4换热器材料的选择 3

第二章 工艺计算 4

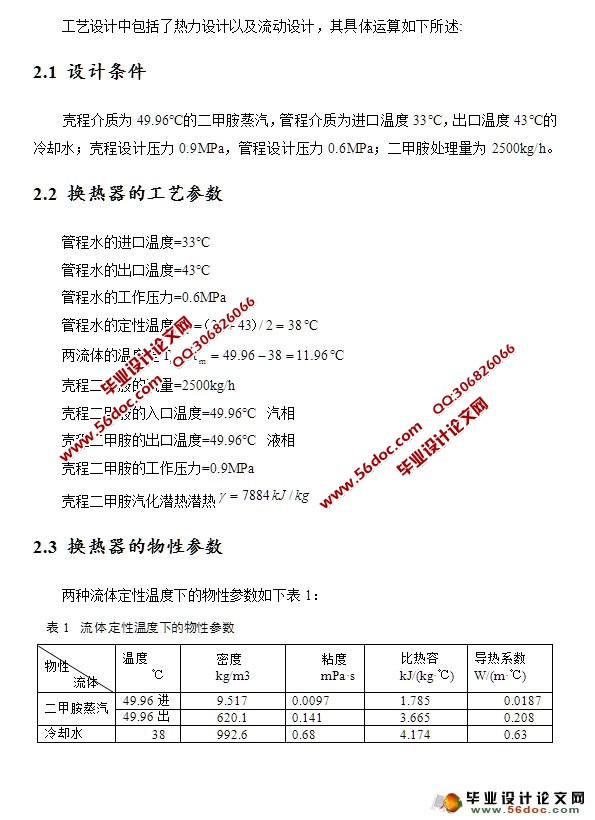

2.1 设计条件 4

2.2 换热器的工艺参数 4

2.3 换热器的物性参数 4

2.4 换热器的设计温度 5

2.5 换热器的类型与流动空间的确定 5

2.5.2 选工艺尺寸计算 6

2.5.3 换热器核算 10

第三章 结构设计 17

3.1壳体、管箱壳体和封头的设计 17

3.1.1壁厚的确定 17

3.1.2 管箱壳体壁厚的确定 18

3.1.3 标准椭圆封头的设计 18

3.2 管板与换热管设计 19

3.2.1 管板 19

3.2.2 换热管 20

3.3 进出口设计 21

3.3.1接管的设计 21

3.3.2 接管外伸长度 21

3.3.3 排气、排液管 21

3.3.4 接管最小位置 22

3.4 折流板或支持板 23

3.4.1 折流板尺寸 23

3.4.2 折流板和折流板孔径 23

3.4.2折流板直径及允许偏差 23

3.4.3 折流板的布置 24

3.4.4 折流板质量计算 24

3.5 防冲挡板 24

3.6 拉杆与定距管 25

3.6.1拉杆的结构和尺寸 25

3.6.2 拉杆的位置 26

3.6.3 定距管尺寸 26

3.7 鞍座选用及安装位置确定 26

第四章 强度计算 31

4.1 壳体、管箱壳体和封头校核 27

4.1.1 壳体校核 27

4.1.2 管箱壳体校核 27

4.1.3 椭圆封头校核 28

4.2 接管开孔补强 28

4.2.1 蒸汽进出口开孔补强 28

4.2.2 管箱冷却水接管补强的校核 30

4.3 膨胀节 31

4.3.1 膨胀节 31

4.3.2 膨胀节计算 31

4.4 管板校核 33

4.4.1 结构尺寸参数 33

4.4.2 各元件材料及其设计数据 34

4.4.3 管子许用应力 35

4.4.4 结构参数计算 35

4.4.5 法兰力矩 36

4.4.6 换热管与壳体圆筒的热膨胀应变形差 37

4.4.7 管箱圆筒与法兰的旋转刚度参数 37

4.4.6 管子加强系数 37

4.4.7 旋转刚度无量纲参数 37

4.4.8 设计条件不同危险组合土况的应力计算 38

4.4.9 四种危险工况的各种应力计算与校核: 39

4.5 设计值总汇 41

第五章 安装使用及维修 42

5.1 安装 42

5.2维护和检修 43

第六章 结论 45

参考文献 46

致谢 47