CK6163纵向进给系统设计(含CAD图,CAXA图,硬件电路设计)

无需注册登录,支付后按照提示操作即可获取该资料.

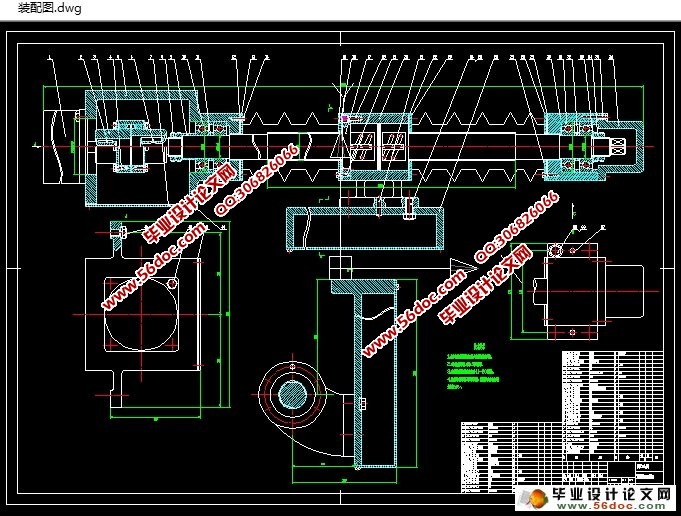

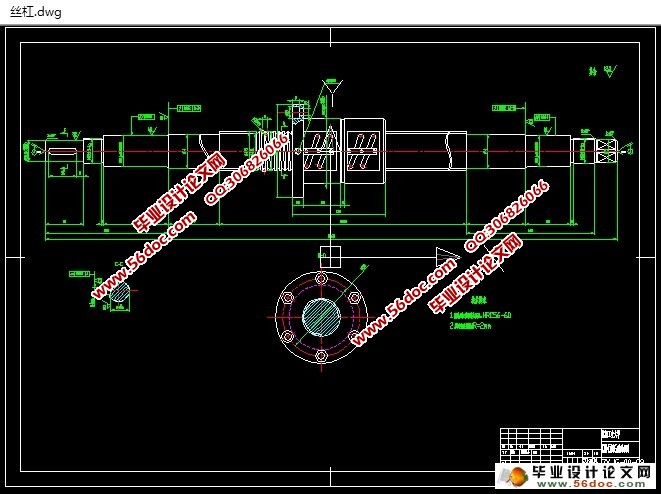

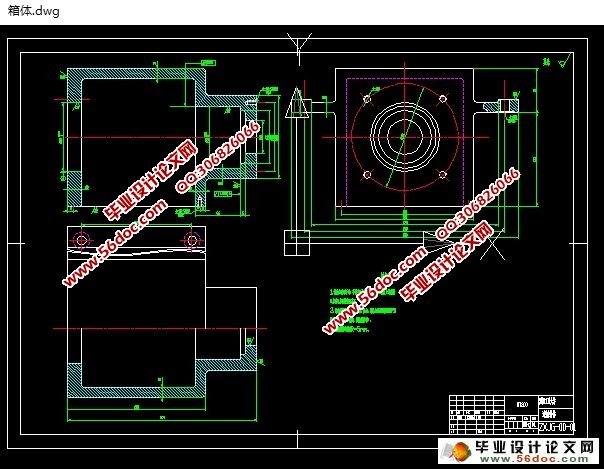

CK6163纵向进给系统设计(含CAD图,CAXA图,硬件电路设计)(任务书,论文说明书24000字,CAD图纸3张,CAXA图纸3张)

摘 要

数控技术是制造业实现自动化、柔性化、集成化生产的基础,现代的CAD/CAM、柔性制造系统、计算机集成制造系统等,都是建立在数控技术基础上的。同时,数控技术也关系到国家战略地位,是体现国家综合国力水平的重要基础性产业核心因素之一,其水平高低是衡量一个国家制造业现代化程度的核心标志。实现加工机床及生产过程数控化,已成为当今制造业的发展方向。推广和应用数控技术是我国机械制造行业的一项重要的战略任务。数控机床的生产准备时间短,所制成的零件重复精度高,对改变零件设计的适用性强,夹具成本低,加工形状复杂的零件时准确可靠。因此,数控机床在现阶段以及以后的一段时间将占据重要地位。

本题目是数控车床CK6163的纵向进给系统设计。首先根据典型工艺数据,结合拟定参数,确定传动方案。对传动系统主要结构进行设计,包括选择滚珠丝杠螺母副和减速箱体的机构设计,从而完成整个进给系统机械结构设计。然后,通过计算选择步进电机,驱动滚珠丝杠运动,从而带动工作台运动。基于AT89C51对步进电机的控制系统设计,使电机实现正反转,快速正反转功能,保证对传动系统的控制要求,从而完成整个进给系统的设计。

关键词:数控机床,滚珠丝杠,步进电机,单片机

Design of CK6163 vertical feed system

Abstract

Numerical control technique is the basic of automation, flexible, integrated, production in manufacturing, modern CAD/CAM, flexible manufacturing systems, computer integrated manufacturing systems are all built on the basic of numerical control technology. At the same time, numerical control technique is related to the strategic importance of a country and it is one of the important foundation industries to reflect the overall national strength of a country, the level of which is the core signs of measuring the modernization of a country’s manufacturing. The realization of the processing of CNC machine tools and production processes has become the development direction of the manufacturing. Popularizing and using numerical control technology is a strategic task in our mechanical manufacturing industry. NC machine tools, which can produce parts with high repeated precision and manufacture complex shape parts with reliability, need no more time to prepare, have more flexibility to alteration of parts, and clamping apparatuses of NC machine tools are very simple. Consequently, NC machine tools will play an important position in mechanical manufacturing at now and a period of time in the future.

The topic is the design of CK6163 vertical feed system. First of all, the solution of transmission will be determined according to the typical technological data and combined with the formulation parameters. Design the main structure of the transmission system, including choice the ball screw and design the structure of the slowdown box, so as to complete the design of mechanical structure of the whole system. Then, choice the stepping motor by calculating, drive the ball screw, which led campaign table. In order to complete the design of feeding system, design the control system of stepping motor based on AT89C51, so that the motor to achieve positive or negative rotating, rapid positive or negative rotating, ensure the control of the transmission system.

Key words: CNC machine tools, ball screw, stepping motor, single-chip

目 录

任务书 i

中文摘要 ii

Abstract iii

第1章 绪论 1

1.1 数控机床的发展历史与现状 1

1.2 发展数控机床的必要性 2

1.3 数控机床的结构与特点 3

1.4 数控机床的发展方向 5

第2章 设计任务与方案确定 7

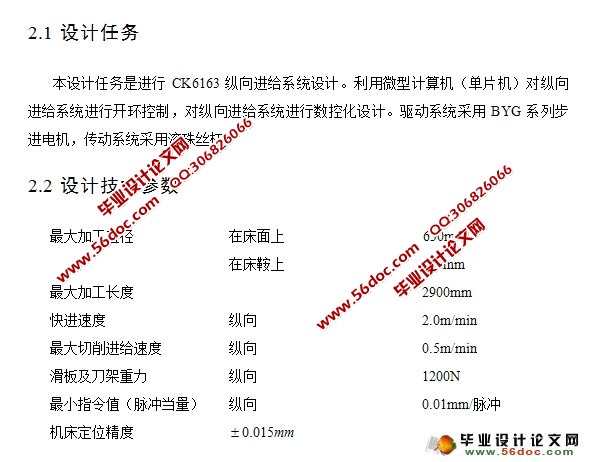

2.1 设计任务 7

2.2 设计技术参数 7

2.3 总体方案的确定 7

第3章 机械传动设计计算 9

3.1 计算内容及步骤 9

3.2 滚珠丝杠设计计算 9

3.2.1 切削力的计算 9

3.2.2 滚珠丝杠螺母副的计算和选型 10

3.2.3 滚珠丝杠螺母副的验算 11

3.3 步进电机的计算与选型 13

3.3.1 步进电机选型 14

3.3.2 传动比的确定 14

3.3.3 转动惯量的计算 15

3.3.4 步进电机转矩校核 16

3.3.5 步进电机性能校核 17

3.4 滚珠丝杠的预紧和消隙 18

第4章 控制系统硬件电路设计 20

4.1 数控系统硬件基本组成 20

4.2 硬件设计方案确定 21

4.3 AT89C51单片机介绍 22

4.3.1 简介 22

4.3.2 AT89C51单片机的引脚介绍 23

4.4 可编程I/O接口芯片扩展 25

4.5 8279介绍 26

4.5.1 8279的结构 26

4.5.2 8279的命令字 27

4.6 环形分配器CH250介绍 31

4.7 程序设计 34

4.7.1 程序流程图 34

4.7.2 程序 36

第5章 环保性与经济性分析 41

5.1 经济性分析 41

5.2 环保性分析 41

第6章 结论 43

参考文献 44

结束语 46

附录 外文文献翻译 47

外文原文 47

中文翻译 54