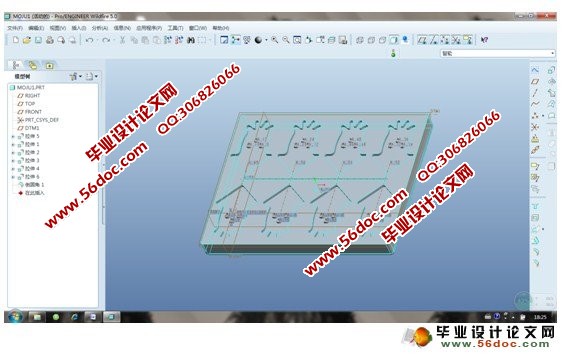

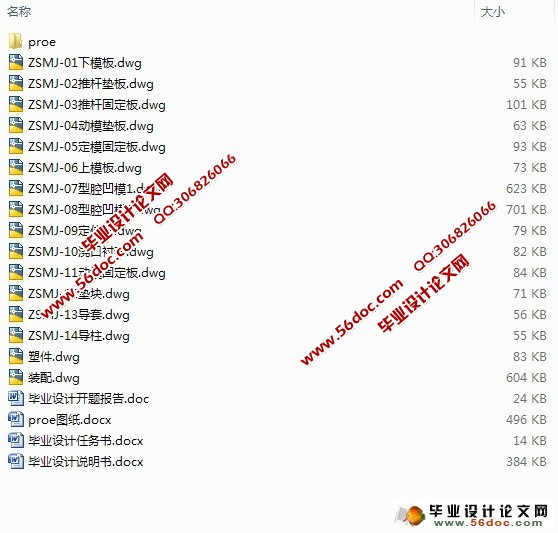

仿真水产素食品机械装备设计-小鱿鱼注塑模具(CAD,Proe三维造型)

无需注册登录,支付后按照提示操作即可获取该资料.

仿真水产素食品机械装备设计-小鱿鱼注塑模具(CAD,Proe三维造型)(任务书,开题报告,论文说明书10000字,cad图纸16张,Proe三维图)

摘要

随着社会的发展及进步,人们从物质追求向精神追求迈进,由于人们对于自身的生活质量越来越关注,在饮食方面不但要吃得好更要吃得健康。因而以魔芋为原料制作的保健素食品越来越受人们的青睐,以魔芋为原料制作零食为儿童及青少年提供了健康的休闲小吃。针对儿童的需求,为了增加食品的食趣与美观,设计卡通鱿鱼外形的模具装备。该模具设计属于注塑类模具,对食品塑件进行造型设计,对模具进行结构设计,使模具结构比较于其他模具简单,美观,提高模具使用效率。

通过这次模具设计,对模具设计及模具结构进行学习,在对模具结构分析及设计的过程中结合机械设计制造及其自动化专业的知识,对本专业知识进行系统的温故知新,并提升CAD绘图水平,加深对本专业的认识,为走出校园进入社会做好准备。

关键词:食品加工;模具设计;注塑模具

Abstract

With the development and progress of society, people from the pursuit of the spirit of the pursuit of material to move, because people more attention to the quality of life and their own, in the diet should not only eat well, eat more healthy. Therefore with Konjac as raw material of health food is more and more popular for the production of raw materials, konjac snacks provide a healthy snack for children and adolescents. According to the needs of children, in order to increase the food items and beautiful food, the shape of the mold and equipment design of cartoon. The design of the mould of injection mould for plastic parts, products design, the structural design of the mold, the mold structure compared to other mold is simple, beautiful, improve efficiency in the use of mold.

Through the mold design, the mold design and mold structure learning, combined with mechanical engineering and automation professional knowledge in the process of the die structure analysis and design of the new system, the specialized knowledge, and enhance the level of the CAD drawing, deepen their understanding of the professional, ready to go out of the campus into the community.

Keywords: food processing; mold design

目 录

摘要 I

Abstract II

1引言 - 1 -

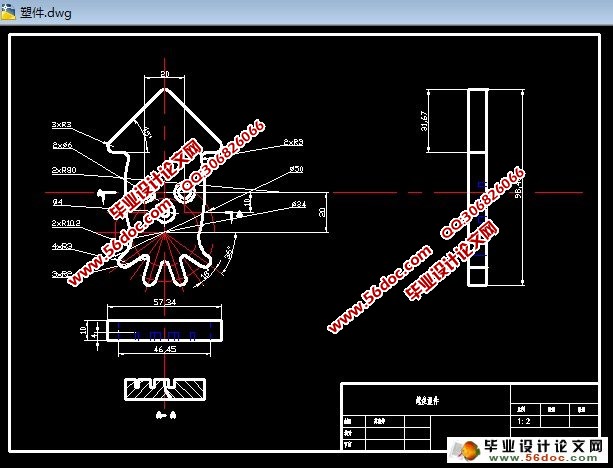

2塑件分析 - 2 -

2.1 食品塑件材料分析 - 2 -

2.1.1 魔芋的基本特性 - 2 -

2.1.2 魔芋材料成形条件 - 2 -

2.2 食品塑件设计 - 3 -

2.2.1 塑件结构设计 - 3 -

2.2.2 塑件尺寸设计 - 3 -

2.2.3塑件成型的工艺参数 - 4 -

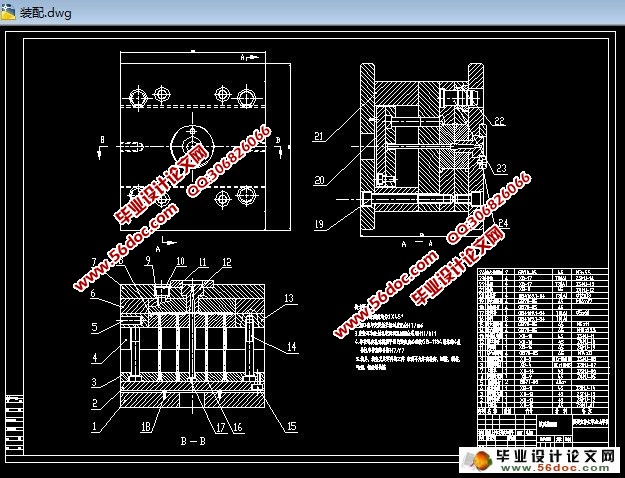

3模具设计 - 6 -

3.1 分型面设计 - 6 -

3.2 型腔布局 - 7 -

3.3浇注系统设计 - 8 -

3.3.1浇注系统组成 - 8 -

3.3.2 浇注系统原则 - 8 -

3.3.3 主流道的设计 - 9 -

3.3.4 分流道的设计 - 10 -

3.3.5 浇口的设计 - 10 -

3.3.6 冷料穴的设计 - 11 -

3.4注射模成型零部件的设计 - 11 -

3.4.1成型零部件结构设计 - 11 -

3.4.2 成型零部件工作尺寸的计算 - 11 -

3.5 排气结构设计 - 12 -

3.6脱模机构的设计 - 13 -

3.6.1脱模机构的选用原则 - 13 -

3.6.2 脱模机构类型的选择 - 13 -

3.6.3推杆机构具体设计 - 13 -

3.7模架及标准件的选用 - 14 -

3.7.1模架的选用 - 14 -

3.7.2标准件的选用 - 14 -

3.8 模具与注射机安装模具部分相关尺寸校核 - 15 -

3.8.1模具厚度(闭合高度) - 15 -

3.8.2 开模行程(S)的校核 - 15 -

3.8.3顶出装置的校核 - 15 -

4模具材料的选用 - 16 -

4.1成型零件材料选用 - 16 -

4.2注射模用钢种 - 16 -

5总结 - 18 -

参考文献 - 19 -

致谢 - 20 -

附件 - 21 -