简易支架冲裁模具设计及制造

无需注册登录,支付后按照提示操作即可获取该资料.

简易支架冲裁模具设计及制造(任务书,开题报告,论文说明书6000字,CAD图纸7张)

摘要

改革开放以来,随着国民经济的高速发展,工业产品的品种和数量不断增加,更新换代不断加快。在现代制造业中,企业的生产一方面朝着多品种、小批量和多式样的方向发展,加快换型,采用柔性化加工,以适应不同用户的需要;另一方面朝着大批量,高效率生产方向发展,以提高劳动生产率和生产规模来创造更多效益,生产上采取专用设备的生产方式。

本文对冲压技术的分类、特点及发展方向作了简略概述;论述了冲压零件的形成原理、基本模具结构与运动过程及其设计原理;对典型的冲压件模具进行了设计:通过本次对支架冲裁模的设计,掌握T10钢材料在落料成型过程中对模具的工艺要求,冲裁模具的结构特点及设计计算的方法,以达到能够独立设计一般冲裁模具的要求。

关键词: 模具设计 冲压模具 pro/E

Abstract

Since reform and opening up, with the rapid development of the national economy, industrial products and the increasing number of varieties, upgrading accelerating. In modern manufacturing, the production on the one hand toward more variety, low-volume and multi-style direction, speed up the change of use of flexible processing, to meet the needs of different users; On the other hand in the large quantities and high The development of efficient production, to improve labor productivity and scale of production to create more efficiency, the production of special equipment to take on the mode of production.

In this paper, punching technology classification, characteristics and development direction of a brief overview; stamping parts discussed the formation of principle, the basic structure and die movement and its design principle of the typical mold of press parts for the design: The right-stent CD-design, master T10 steel blanking in the process of forming the mold of the requirements of the structural characteristics of punching die design and the method of calculation, can be independently designed to meet the general requirements of the punching die.

Key word: Mold design, ramming mold pro/E

目录

1绪论 …………………………………………………………………… (1)

1.1 冲压的概念、特点 …………………………………………… (1)

1.2 冲压的基本工序及模具 …………………………………………(1)

2. 设计过程 ………………………………………………………………(3)

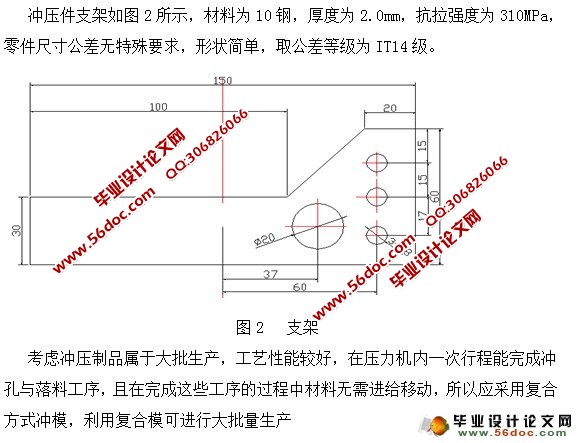

2.1 冲压制品 ………………………………………………………(3)

2.2 冲压件工艺分析,确定工艺方案 ………………………………(3)

2.3 排样的设计 ……………………………………………………(4)

2.4 计算冲裁力,选用压力机 ………………………………………(5)

2.5 压力中心的计算 ………………………………………………(5)

2.6 计算主要零件的尺寸……………………………………………(6)

2.7 模架的选择: ………………………………………………… (9)

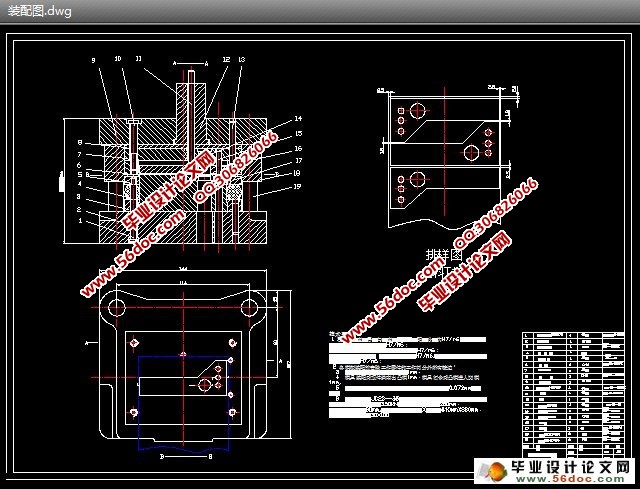

2.8 模具的装配 …………………………………………………(10)

2.9 校核 …………………………………………………………(11)

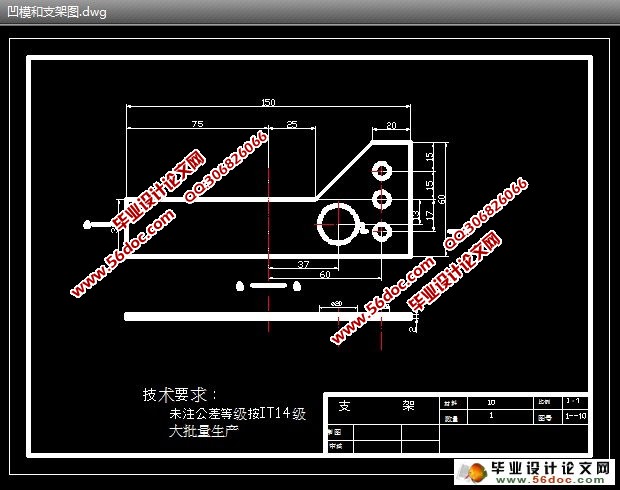

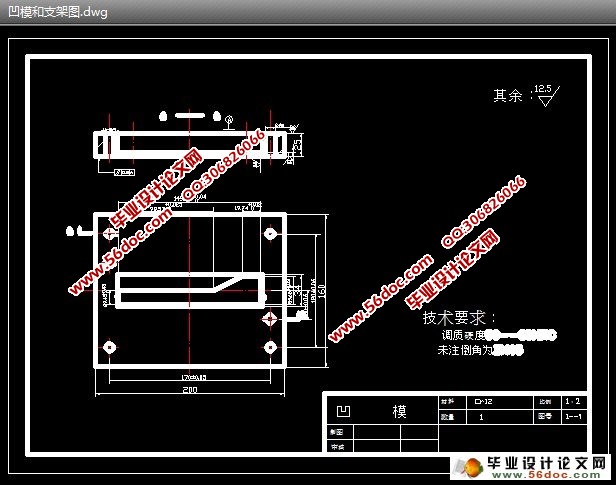

3.冲裁模具凹凸模加工工艺的编制…………………………………………(11)

3.1落料凹模加工工艺过程…………………………………………… (11)

3.2冲孔凸模加工工艺过程…………………………………………… (12)

设计总结 …………………………………………………………………(13)

参考资料 …………………………………………………………………(14)