汽车玻璃升降器外壳模具设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

汽车玻璃升降器外壳模具设计(含CAD零件图装配图)(开题报告,中期检查表,论文说明书12800字,CAD图11张)

摘 要:我设计的是个小型的冲压模具,其质量和体积都较小,结合零件本身的特点确定合适的设计理念和设计思路,这样就不会产生设计出的模具无法使用或生产出的零件无法满足其使用性能等致命问题的出现[1]。结合我国近年来模具的发展历史,虽然在设计制造方法和手段方面已基本达到了国际水平,模具结构功能方面也接近国际水平,在轿车模具国产化进程中前进了一大步,但在制造质量、精度、制造周期等方面,与国外相比还存在一定的差距。所以我所设计的模具要考虑到更多的方面,结合我的实际情况,多方考察找到适合自己优点的地方,这样不仅可以设计出合格的模具产品,还能提高自己的能力。

关键词:落料;拉深;设计

The Shell Mold Design of Glass Lifter in An Automobile

Abstract:Both the mass and volume of the stamping dies I designed are small with the combination of the components. I have proper designing concepts and ideas, so as not to meet some fatal problems. such as the mold can’t be put into use, or the components can’t meet the performance. Although the manufacturing. And designing methods and means have basically reached the international level, as well as the mold structure and function. a big step forward in the process of localization in the car mode, our quality, accuracy and cycle of manufacture have some gaps compared with foreign countries. So I have to design the mold to take into account more aspects. With my actual situation and careful inspection , I can not only design a qualified mold products but also I will improve my ability .In this design, I make the contents more detailed and clear though my professional and learned knowledge, text explanation, design legend and tables.

Key words:blanking; drawing; design

目 录

摘 要 I

关键词 I

1 前言 1

2 零件的冲压工艺性分析 2

2.1 零件的使用条件和技术要求 2

2.2 冲压工艺性分析 2

2.3 确定工艺方案 3

3 有凸缘筒形件的确定 5

3.1 工艺计算 5

3.2 计算拉深次数 6

4 工艺计算 5

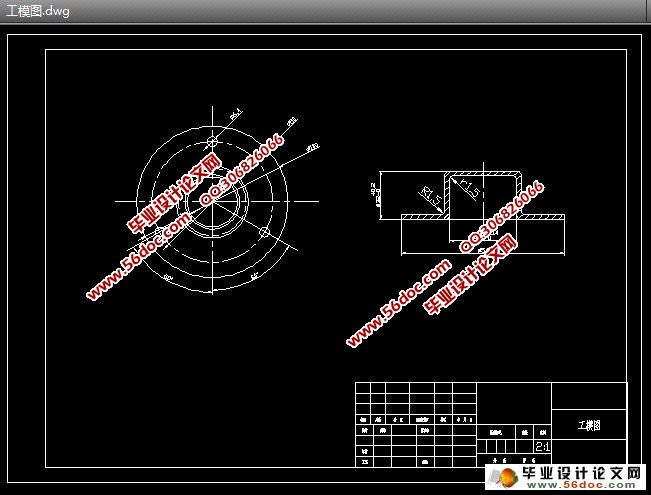

4.1 确定排样、裁板方案 5

4.2 确定各工件中间尺寸 9

4.3 计算各工序压力 10

4.4 选用压力机 14

5 模具工作零件设计 14

5.1 确定冲裁间隙 14

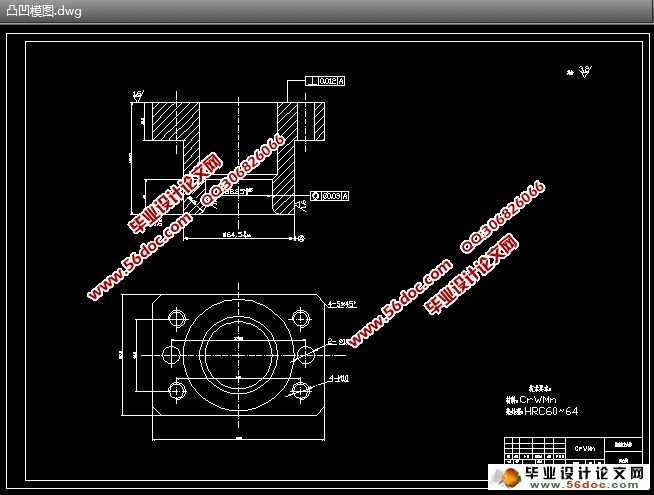

5.2 凸、凹模尺寸计算 14

5.3 拉深凸、凹模的间隙 17

6 模具其它零件的选取和设计 19

6.1 模架选择 19

6.2 打料推杆尺寸: 20

6.3 导柱与导套 20

6.4 模柄 21

6.5 定位零件 21

6.6 卸料件与推件零件 21

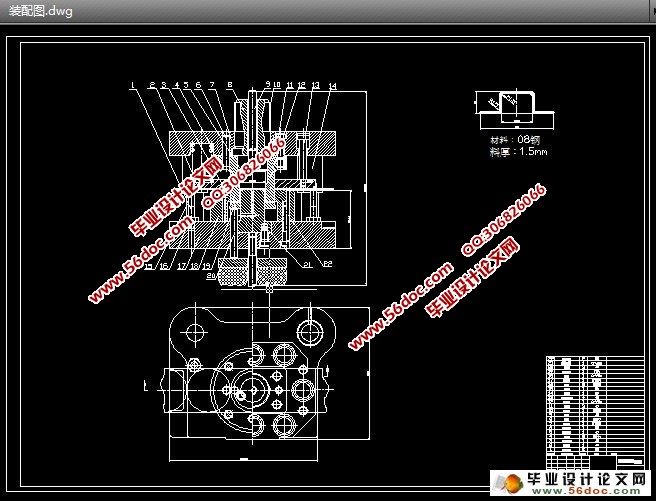

7 模具总装图 23

8 模具的装配与调试 24

8.1 模具的装配 23

8.2 模具的调试 24

设计总结 25

致谢 28

参考文献 29