挡片冲孔落料冲压模具设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

挡片冲孔落料冲压模具设计(含CAD零件图装配图)(文献综述,设计说明书10000字,CAD图11张)

摘 要

在本次设计中根据所给题目的要求,首先对冲压件进行了分析,分析该零件的尺寸精度得出用一般精度的模具即可满足零件精度的要求,再从零件的形状、尺寸标注及生产批量等情况看,选择加工方案。由于模具工业的重要性,模具成型工艺在各个工业部门得到了广泛的应用,使得模具行业的产值已经大大超过机床刀具工业的产值.这一情况充分说明在国民经济蓬勃发展的过程中,在各个工业发达国家对世界市场进行激烈的争夺中,越多越多地采用模具来进行生产。

因此,要使国民经济各个部门获得高速发展,加速实现社会主义四个现代化,就必须尽快将模具工业搞上去,使模具生产形成一个独立的工业部门,从而充分发挥模具工业在国民经济中的关键的作用. 本设计挡片零件冲压模具,凸凹模安装在模具下模座上。倒装复合模废料清理无须二次清理,操作方便安全,生产效率较高。复合模与弯曲模的设计过程大致相似,复合模较弯曲模结构更为复杂。设计上主要是对凸模、凹模和凸凹模的设计,其中主要是其工作部分的尺寸设计,以保证制件的精度和质量要求。

关键词:模具 冲裁件 凸模 凹模 凸凹模

ABSTRACT

In this design according to the requirements of the topic, firstly, stamping parts are analyzed, the dimensional accuracy of the parts of the analysis that the general accuracy of the mould can meet the requirements of precision parts, from the shape, dimension and mass production situation, selection and processing scheme. Due to the importance of the mold industry, mold forming technology has been widely used in various industrial sectors, so that the mold industry output value has been greatly exceeded the machine tool industry output value. This fully explained in the process of national economy vigorous development, in the fierce competition for each industrial developed countries on the world market, more and more using mold for production, key technology and national economic development has become the mold industry obviously.

Therefore, to make each department of national economic high speed development, accelerate the realization of the four modernizations of socialism, we must mold industrial make up as soon as possible, so that the mold production formed an independent industrial sector, so as to give full play to the key role of mold industry in the national economy. The design of bending plate stamping bracket parts of the die, punch and die installed in the mould of the lower mould seat. Flip composite modulus waste disposal, without two clean, convenient and safe operation, high production efficiency. The design process of compound die and bending die compound die is similar, the bending die structure is more complex. The design is mainly the design of the punch, concave die and punch and die, which is mainly designed dimension of the part of the work, to ensure the precision and quality requirements.

Keywords: die blanking punch punch die

目 录

•摘 要 2

ABSTRACT 3

目 录 4

绪 论 5

第一章 工艺分析 7

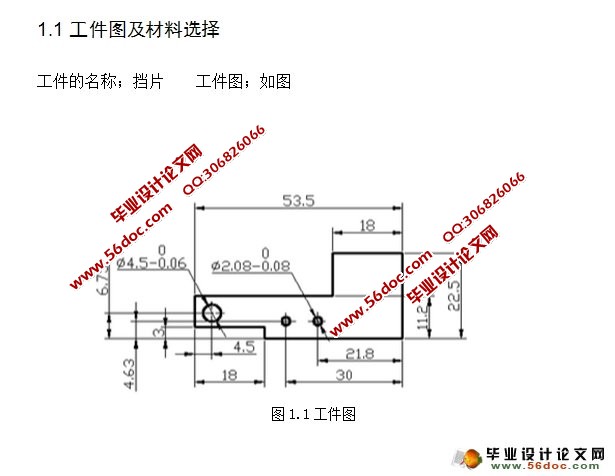

1.1工件图及材料选择 7

1.2尺寸精度的确定 8

1.3 确定工艺方案 9

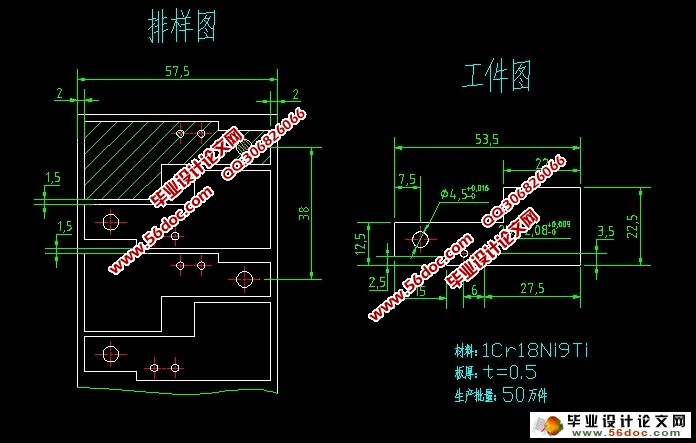

1.4排样的计算 9

1.5材料利用率的计算 12

第二章 模具的总体设计 14

2.1类型的选择 14

2.2 操作和定位方式 14

2.3 卸料,出件方式及确定送料,导向方式 14

第三章 冲压力的计算和压力机的选择 15

3.1冲裁力 15

3.2卸料力和顶料力的计算 15

3.3总的冲压力 16

3.4压力机的初选 16

第四章 模具压力中心的计算 18

4.1压力中心的影响和确定 18

4.2计算压力中心 18

第五章 冲裁间隙的分析及确定 20

第六章 凸模和凹模的设计及计算 22

6.1刃口的计算 22

6.2凸凹模计算 22

6.3落料的设计计算 24

第七章 零件的结构设计 26

7.1 凹模的设计 26

7.2 凸模的结构设计 27

7.3凸模材料的应用 28

7.4 各零部件的设计 29

第八章 校核闭合高度和压力机的参数 34

8.1闭合高度 34

8.2压力机的选定 34

结 论 37

参考文献 39