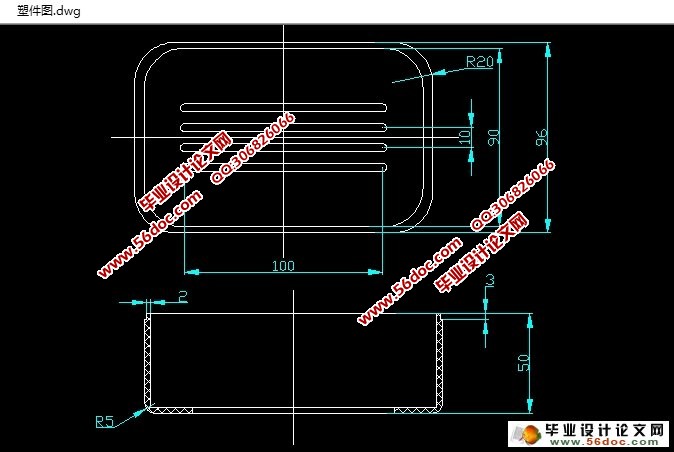

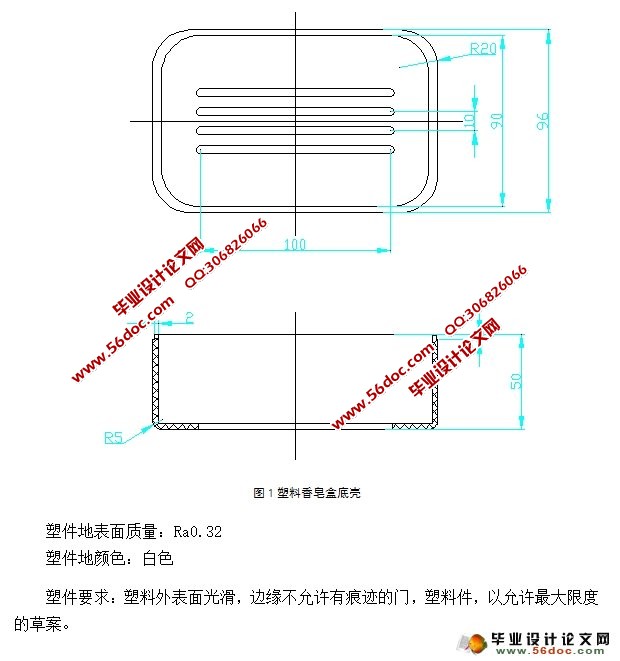

香皂盒底壳塑料模具设计(含CAD零件图装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

香皂盒底壳塑料模具设计(含CAD零件图装配图)(文献综述,设计说明书11000字,CAD图6张)

摘 要

本次设计主要是设计一个用于肥皂盒的模具,塑料件的工艺分析与比较,最后设计了一套注塑模具。本设计从产品结构、工艺、模具结构、模具浇注系统、模具成型零件的结构、系统的顶部、冷却系统、注塑机及相关参数的校核,有详细的设计,同时又简单的制模工艺。通过整个设计过程,表明该模具能达到塑件所需的加工工艺。根据课题设计的主要任务是对马桶的注塑模具进行设计。即一对注塑模具的设计,生产肥皂盒塑料制品,以实现自动化,提高生产。根据卫生间的肥皂盒的具体结构,该模具是一个单分型面注射模的侧浇口。根据模具设计,模具可以达到的质量的香皂盒和加工技术。同时,在设计过程中,通过查阅大量资料、手册、标准、期刊等,结合教材知识也对注塑模具结构(注塑件、浇注系统、导向、发射、排气系统、模具温度控制系统)是一个系统的知识,拓宽视野,丰富知识,为将来独立完成模具设计积累了一定的经验。

关键词:香皂盒; 塑料模具; 分型面; 注塑机

Abstract

This design is mainly directed against the soap box die design, through the technology of plastic parts for analysis and comparison, the final design an injection mold. The design process from the product structure, the structure of the specific die, die casting, mold forming part of the structure, the roof system, cooling system, the choice of injection molding machines and related parameters of the check, have the detailed design, And the establishment of a simple mold processing technology. Through the entire design process that the mold plastic parts can achieve this by the requirements of the processing technology. According to Title Design's main task is to soap box injection mold design. Which is designed to produce an injection mold plastic parts soap box products, so as to improve the automation of production. Soap box for the concrete structure, the die is the side gate of the single type of injection molds. Through die design show that the mold to achieve the quality of soap box and processing requirements.At the same time, in the design process, through access to vast amounts of data, manuals, standards, periodicals, etc., with materials on the knowledge of the injection mold of the structure (forming parts, casting, direction of the launch, the exhaust system, Die-conditioning) system with the understanding, broaden the horizons and enrich the knowledge, complete independence for the future die design has accumulated some experience.

Key words:soap boxes; plastic; molds type face,; injection machine

目 录

绪 论 1

1 塑件工艺分析 2

1.1 塑件设计要求 2

1.2 塑件的材料特征 3

1.2.1 ABS材料 3

1.2.3 主要性能 4

2 塑件的尺寸精度与结构 6

3 注射机及模架的选用 8

3.1 注射机的选用 8

3.2 模架的选用 8

3.3 模架周界尺寸选择 9

4 模具结构设计 10

4.1 制品成型位置及分型面的选择 10

4.2 模具型腔数的确定、排列和流道布局 10

4.3 主流道、主流道衬套及定位环的设计 11

4.4分流道的形状及尺寸 13

4.5 浇口的形状及其位置选择 15

4.6 导向机构的设计 16

4.7 推出机构的设计 17

4.8 拉料杆的形式选择 18

4.9 模具排气槽设计 18

5模具型腔、型芯的有关计算 19

5.1 型腔工作尺寸计算 19

5.2 型芯的工作尺寸计算 19

6 注塑机参数校核 22

6.1 最大注射量校核 22

6.2 锁模力校核 22

6.3 模具与注塑机安装部分相关尺寸校核 23

6.4 模具闭合高度校核 23

6.5 开模行程校核 23

7 模具冷却系统计算 24

7.1 冷却回路所需的总面积计算 24

7.2 冷却回路的总长度的计算 25

7.3 冷却水体积流量的计算 25

8 注射模零件及总装技术要求 27

8.1 零件的技术要求 27

8.2 总装技术要求 27

9 模具装配图及工作原理 29

结 论 30

致 谢 31

参考文献 32