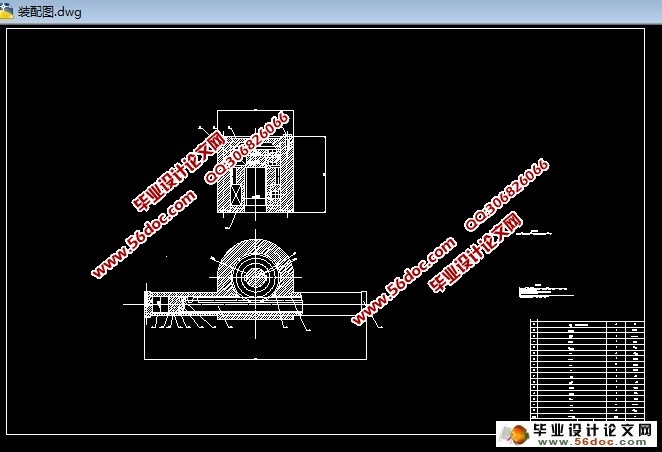

DZK40齿轮齿条式摆动缸的设计(含CAD零件图和装配图)

无需注册登录,支付后按照提示操作即可获取该资料.

DZK40齿轮齿条式摆动缸的设计(含CAD零件图和装配图)(任务书,开题报告,毕业论文说明书22900字,CAD图纸4张)

[摘要] DZK40齿轮齿条摆动液压缸,属新型机械设备领域中的液压执行元件,该设备由缸体、缸盖、齿条、齿轮轴、轴承等组成。在缸筒内对称装有活塞,与缸筒端面中心以螺纹连接与齿轮轴相啮合的齿条轴,齿条轴装在缸体内,启动液压传动,活塞就左、右推动齿条使齿轮轴往复摆动。将液压缸的往复运动通过齿条带动齿轮,转化成齿轮轴的正反向摆动旋转,同时将往复缸的推力转化成齿轮轴的输出扭矩。由于齿轮轴的摆动角度与齿条的长度成正比,因此齿轮轴的摆角可以任意选择,并能大于360°。摆动液压缸最突出的优点是无需任何变速机构就可使负载直接获得往复摆动运动。本设计采用脚底式连接,轴输出,双齿条机构,540°大摆角。通过总体结构方案确定,几何参数的计算及结构设计以及连接方式、密封件的选型和缓冲装置、排气装置的设计。此外,这次设计还进行了液压缸三维造型设计,通过绘制整体三维模型和其他局部模型,进一步提高了对此类摆动液压缸的认识。最后,对主要受载零件进行强度分析和校核,对其进行了优化分析。

[关键词] 摆动液压缸;齿轮轴;设计计算

The Design of the DZK Gear and Rack Swinging Hydraulic Cylinder

[Abstract] The DZKGear and Rack Swinging hydraulic cylinder, is the hydraulic actuator in the new mechanical device domain. This equipment is consisted of the cylinder block, cylinder head, rack, gear shafts, bearings and other components. The piston is symmetrically located in the cylinder tube, with the cylinder tube end surface center the rack axis which meshes by the screw joint and the gear shaft, the rack axis installs in the cylinder body, start the hydraulic transmission, the piston impetus the rack swinging on the left and right and causes gear shaft reciprocation.. Drives the gear hydraulic cylinder's reciprocal motion through the rack, transforms permanent tooth wheel axle's forward and reverse swinging revolving, simultaneously will move back and forth cylinder's thrust force transformation permanent tooth wheel axle's output torque. Because gear shaft's swinging angle and rack's length is proportional, therefore gear shaft's pivot angle may the arbitrary selection, and can be bigger than 360°. The swinging hydraulic cylinder most prominent merit does not need any gearshift mechanism to be possible to cause the load to obtain the reciprocation oscillating motion directly. This design uses the foot-type connection, the axis output, the double rack organization and 540° the great pivot angle, determined through the gross structure plan, geometric parameter's computation and the structural design as well as the connection mode, the seal shaping and the buffer mechanism, air exhaust device's design. In addition, this design also conducted three-dimensional modeling of hydraulic cylinder design, and we can further increase its awareness of such oscillating cylinder by drawing the overall three-dimensional mode and other local models. Finally, we do Ansys analysis for the hydraulic cylinders we designed, and analysis and checking main strength of the force components so that to further optimize the analysis.

[Key words] swinging hydraulic cylinder; Gear shaft; Foot-type connection Finite Element Analysis

1.3 本文的研究内容

主要研究内容:

(1)齿轮齿条液压摆动缸的概况;

(2)齿轮齿条液压摆动缸结构方案;

(3)齿轮齿条液压摆动缸基本参数的设计计算;

(4)齿轮齿条液压摆动缸结构设计;

(5)强度校核

原始数据:

(1)额定扭矩1200 Nm;

(2)摆动角度0 - 360°;

(3)液压源额定压力16 MPa。

目 录

毕业设计(论文)任务书 Ⅰ

开题报告 Ⅱ

指导教师审查意见 Ⅲ

评阅老师评语 Ⅳ

答辩会议记录 Ⅴ

中文摘要 Ⅵ

外文摘要 Ⅶ

1 前言 1

1.1 选题的意义 1

1.2 齿轮齿条摆动液压缸的研究现状和发展方向 1

1.3 本文的研究内容 1

2 摆动缸结构方案确定 2

2.1 缸体 2

2.2 缸盖 2

2.3 缸筒 3

2.4 活塞 4

2.5 活塞杆 6

2.6 活塞杆的导向、密封和防尘 7

2.7 液压缸的缓冲装置 9

2.8 液压缸的排气装置 11

2 .9 密封结构设计 12

3 几何参数的计算及结构设计 16

3.1 齿轮齿条传动及齿轮轴的设计 16

3.2 液压缸主要几何尺寸及结构尺寸的计算 22

4 三维造型设计 25

4.1 三维模型设计 25

5 总结 28

参考文献 29

致 谢 30

附录 31