井口装置闸阀设计

无需注册登录,支付后按照提示操作即可获取该资料.

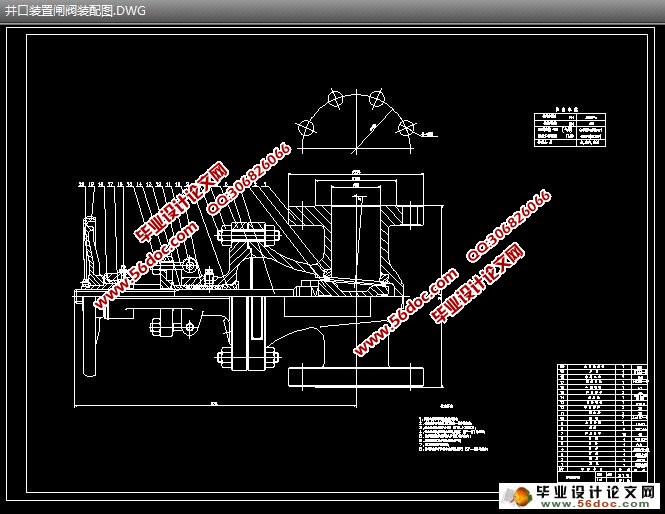

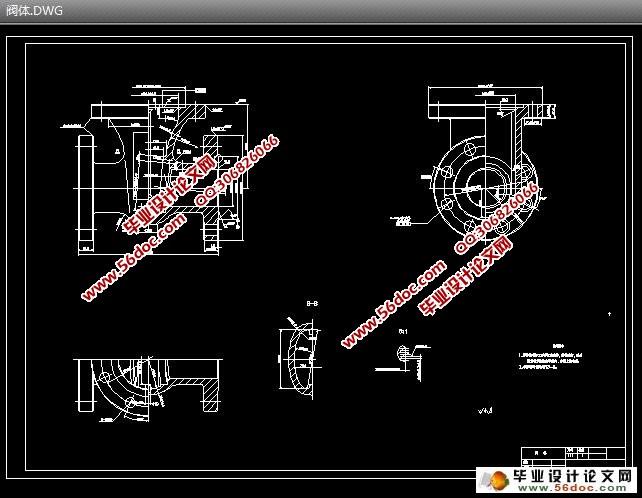

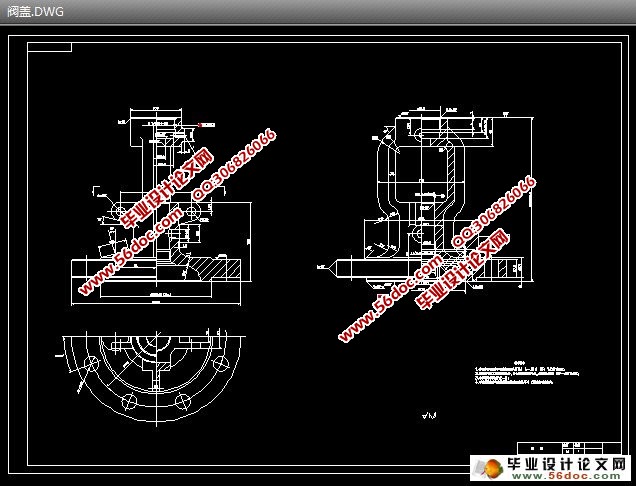

井口装置闸阀设计(任务书,开题报告,毕业论文说明书23000字,CAD图纸3张)

[摘要]采油井口装置闸阀是油气开采的重要设备,由套管头、油管头、采油树三部分组成,用来连接套管柱、油管柱,并密封各层套管之间及与油管之间的环形空间,并可控制生产井口的压力和调节井口装置及采油节油井口流量,也可用于酸化压裂、注水、测试等特殊作业, 能满足不同工况,密封可靠,工作安全。其中,井口闸阀作为采油井口装置中最核心的设备,起着开启或截断介质并控制其按需要流动的作用,其设计的合理性、便捷性对于采油井口装置整体设计合理性的提高有着重要意义。

钻采工艺要求采油井口装置用的闸阀具有操作轻便灵活、密封可靠、通道流畅、流阻系数小、寿命长、结构简单、制造工艺性好以及成本低等特点。此外,随着我国石油工业的发展,井口装置所需悬挂油管的尺寸日益增加,相应的井口装置也需不断进行改进,因此,采油井口装置在国内外受到极大的关注。本文将对工作压力为25MPa和试验水压为52MPa的井口闸阀进行设计与分析。

石油工业的发展不断地对井口装置以及阀门的可靠性和控制性提出更高的要求,这便促使井口装置也处在不断的发展之中。就井口闸阀来看,启闭阀板的力矩、闸板的楔住、闸门的密封和闸阀的使用寿命是提高闸阀工作性能必须考虑的几个问题,也是闸阀设计与分析的主要研究方向。其中,闸阀的密封是闸阀性能的最重要指标之一。本文分析对比了各种典型的闸阀结构,选择出符合本设计要求的主要结构型式和材料,设计出一种明杆式平行单闸板闸阀。主要侧重点在于单闸板的结构分析与启闭力矩及强度校核、中法兰的设计与校核等。

[关键词]井口闸阀;平行单闸板;设计计算

Wellhead valve 3D design based on SolidWorks

[Abstract] Oil producing wellhead valve is an important ground equipment which is used for producing oil or gas, it is composed of a casing head, a tubing head and a Christmas tree. It also used for collecting the casing string and the tubing string, and sealed the annular space between every sleeve and the pipeline. It can also control the pressure of the wellhead, and regulate the wellhead device and the flow of the wellhead of oil extraction. Besides, it can used for some special work, such as fracture acidizing, water injection and testing, it can meet different working condition, and reliable sealing, work security. And the wellhead gate valve, as the most important equipment, is used to open or cut off media flow and control the flow direction as needed. The reasonable and convenient of its designing is great important to the oil producing wellhead device in its reasonably design.

Drilling and production technology requires the wellhead gate valve which is used for oil producing wellhead device should have several characteristics, such as light and nimble operation, reliable sealing, smooth channel, small coefficient of flow resistance, long operation life ,simple structure, manufacturing manufacturability good and cheap.Besides, with the development of our contry’s oil industry, the size of the pipeline hang on the wellhead device increasing day by day, the corresponding wellhead device also needs continual improvement. So oil wellhead device received much attention from home and abroad. In this paper, the author give a design and analysis for the gate valve whose working pressure is 25MPa as well as52MPa for the test of hydraulic pressure.

The continuous development of the oil industry leads to higher request on the reliability and control ability of the oil producing wellhead equipment, which also contribute to the fast development of the wellhead gate valve. To the wellhead gate valve, on-off switch torque, the gate disc’s structure, valve body’s strength, seal performance and service life are several issues which supposed to be considered on the working performance of the gate valve, and is the main research directions. And the seal of the valve is one of the most important index of the valve’s performance. This article analyzes a variety of typical valve structures, and chooses more suitable structures and materials to meet the requirement of this design, and designs a parallel single disc rising stem gate valve. The main focus is the analysis in structure and on-off switch torque calculation of the open-style single disc, the design and validate of the middle flange, etc.

[Key words] Wellhead gate valve; parallel single disc; design and calculation

25MPa井口闸阀的尺寸

依设计要求,公称通径为65mm,孔径为65mm,闸阀结构长度为669mm。

主要研究内容

(1)井口装置闸阀结构设计方案分析;

(2)井口装置闸阀相关零件强度计算;

(3)井口装置闸阀零部件图和总装配图各一套;

(4)主要零部件设计计算与校核。

关键问题

(1)井口装置闸阀相关部件强度计算于校核;

(2)提高闸阀的密封性能,降低内部摩擦力;

(3)提高闸阀的强度和耐腐蚀能力。

目 录

前言 1

1 选题背景 2

1.1 井口闸阀简介 2

1.2 国内外采油井口装置及其闸阀现状和发展趋势 3

2 25MPA井口闸阀总体方案设计与分析 5

2.1 井口闸阀的功能 5

2.2 主要结构分析 5

2.3 闸阀的连接方式 7

2.4 该闸阀的通径和结构长度 7

3 25MPA井口闸阀设计计算 9

3.1 闸阀设计条件 9

3.2 中低压井口闸阀材料选择 9

3.3 阀座、闸板密封面的设计计算 11

3.4 阀杆的设计及强度验算 14

3.5 阀杆螺母的计算与校核 18

3.6 闸板的计算与校核 19

3.7 阀体的计算与校核 19

3.8 阀体中法兰的计算与校核 22

3.9 联接螺母、螺栓的强度校核 27

3.10 阀盖的强度校核 28

3.11 手轮总转矩及圆周力的计算 29

4 总结 30

参考文献 30

致谢 32

附录 33