座椅支架冲压工艺分析及其模具设计

无需注册登录,支付后按照提示操作即可获取该资料.

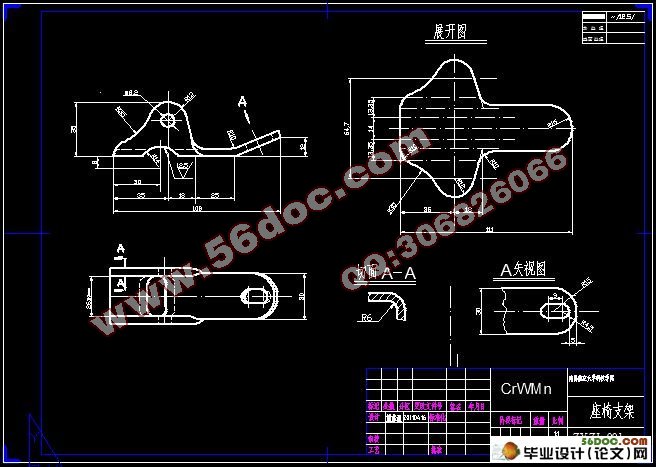

座椅支架冲压工艺分析及其模具设计(开题报告,外文翻译,论文说明书14000字,CAD图纸6张,冲压工艺规程卡)

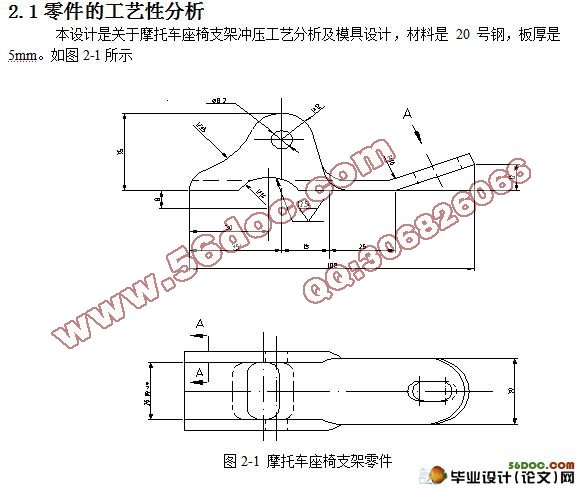

摘要:本设计课题给定的是某摩托车座椅支架,形状简单,同时包括冲裁和弯曲两道工序,其中弯曲相对比较简单。在本次设计中关键的地方是合理的选择模具间隙,在模具的设计中间隙直接影响着冲裁件的质量,所以合适的间隙的选择应以工件断面质量、冲裁件精度、模具寿命和加工质量四项为依据,并且进行适当的分类。在模具设计部分重点在于凸、凹模的设计,它们都要先进行试模合格以后再热处理,因为它影响着冲裁件是否合格。

由于本零件属于大批量生产,而且制作精度要求不高,需要多工序冲成的小型零件。所以冲裁我选择了级进模,以便能满足制造要求的同时也增加了操作的安全性及减少模具和设备的数量,从而减少车间的占地面积。

由于本人水平有限,本论文中必然存在不少纰漏及错误之处,敬请评阅老师批评指正。

关键词:冲裁间隙 级进模 段面质量 模具寿命

Chair support ramming craft analysis and its mold design

Abstract: This design topic assigns is some motorcycle chair support, the shapeis simple,

Simultaneously includes falls the material and the curving two workingprocedures, curving relative quite is simple. In this design the essential place is the reasonable choice mold gap,the gap directly affects in the mold design is falling the materialquality, therefore the appropriate gap choice should take the workpiece cross section quality, fall the material precision, the moldlife and the processing quality four items as the basis, and carrieson the suitable classification. Partial key raised lies in, theconcave mold design in the mold design, they all will want theadvanced line of examination mold qualified later in the heattreatment, because it will affect is falling the material will bewhether qualified.

Because this components belong to the mass production, moreover themanufacture precision request is not high, needs the small componentswhich the multi- working procedures flushes. Therefore the cut die hadme to choose the level to enter the mold, in order to could satisfythe manufacture request at the same time also to increase theoperation security and the reduced mold and the equipment quantity,thus reduced the workshop the area. Because myself level is limited, in the present paper inevitably hasmany careless mistakes and the mistake place, asks respectfully tocomment reads teacher to criticize points out mistakes.

Keyword:chongcai gap The level enters the mold Section surface quality

Mold life

序号 图号 图纸名称 图幅

1 ZYZJ-000 座椅支架装备图 A1

2 ZYZJ -001 座椅支架零件图 A2

3 ZYZJ -002 落料凹模图 A2

4 ZYZJ -003 落料凸模图 A2

5 ZYZJ -004 冲孔凸模图 A2

6 ZYZJ -005 弯曲前毛胚样本 A2

目录

第一章 绪论

1.1 选材的依据及课题的意义…………………………………………………(1)

1.2 模具行业现状及发展趋势…………………………………………………(1)

1.3 内容几实验方案……………………………………………………………(2)

1.4 主要特色几工作进度………………………………………………………(2)

第二章 工艺方案分析………………………………………………………(3)

2.1 零件的工艺性分析…………………………………………………………(3)

2.2 加工工艺方案的确定………………………………………………………(4)

第三章 冲裁模设计……………………………………………………… (4)

3.1 毛胚尺寸计算及工艺分析…………………………………………………(4)

3.1.1 毛胚尺寸计算…………………………………………………………… (4)

3.1.2 冲裁工艺分析…………………………………………………………… (5)

3.2 工件排样与搭边……………………………………………………………(6)

3.2.1排样……………………………………………………………………… (6)

3.2.2 搭边……………………………………………………………………… (8)

3.3 冲裁间隙……………………………………………………………………(9)

3.4 冲裁力的预算………………………………………………………………(9)

3.5 模具压力中心的计算…………………………………………………… (11)

3.6 凸凹模刃口尺寸的计算………………………………………………… (12)

3.7 模具的总体设计………………………………………………………… (17)

3.7.1 冲模的闭合高度…………………………………………………………(17)

3.8 机构件与标准件的选用………………………………………………… (17)

3.8.1 模架…………………………………………………………………… (17)

3.8.2 模座…………………………………………………………………… (18)

3.8.3 模柄…………………………………………………………………… (18)

3.8.3定位装置…………………………………………………………………(18)

3.9 冲模设备选择…………………………………………………………… (18)

3.9.1 冲裁设备类型的选择………………………………………………… (18)

3.9.2 压力机选用原则……………………………………………………… (19)

第四章 弯曲模设计………………………………………………………(20)

4.1 分析零件的冲压性………………………………………………………(20)

4.2 弯曲回弹…………………………………………………………………(22)

4.2.1 影响回弹量的因素………………………………………………………(22)

4.2.2 减少回弹量的措施………………………………………………………(23)

4.3 进行弯曲力的计算……………………………………………………… (24)

4.4 估算模具的各部分尺寸 初步选择压力机和模架………………………(25)

4.5 主要部件的初步设计及选用…………………………………………… (26)

4.6 模架 导柱 导套及模柄的选用………………………………………… (27)

4.7 压力机的选用………………………………………………………………(27)

4.8 标准件的选用………………………………………………………………(27)

参考文献……………………………………………………………………… (30)

致谢………………………………………………………………………………(31)

附录A……………………………………………………………………………(32)