JN-A型米粉挤丝机零部件的设计

无需注册登录,支付后按照提示操作即可获取该资料.

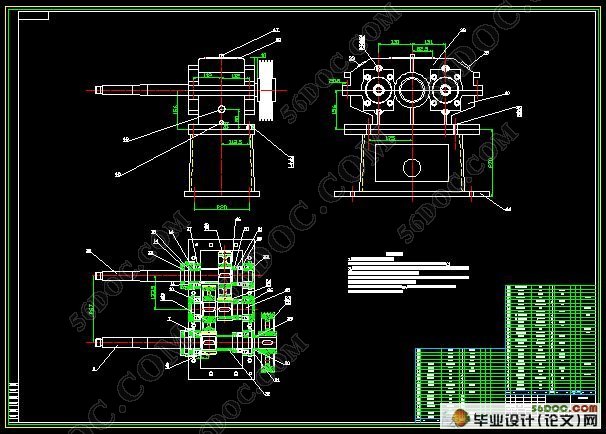

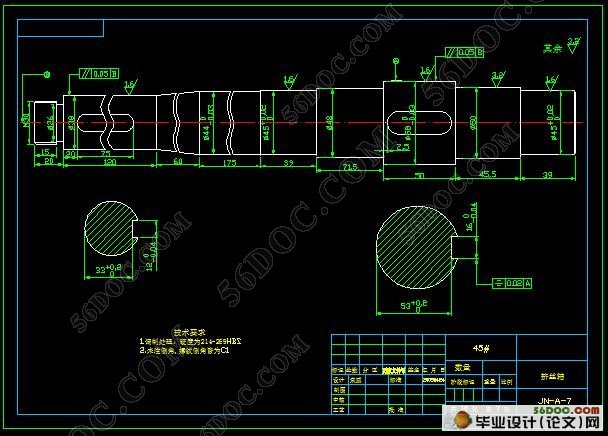

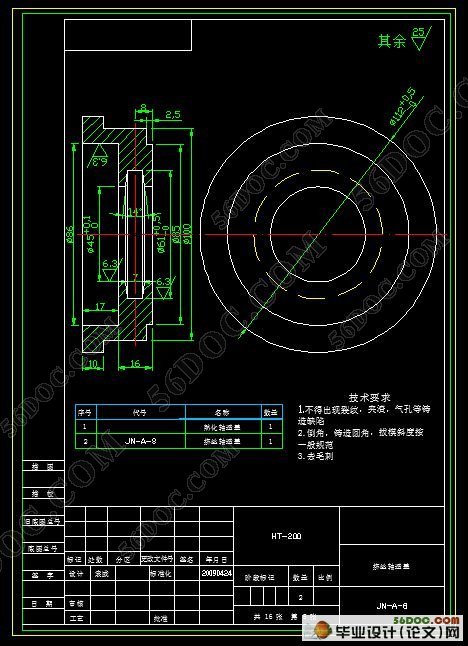

JN-A型米粉挤丝机零部件的设计(任务书,论文说明书7000字,答辩幻灯片ppt,cad图纸)

摘要

米粉生产都是沿用传统工艺和手工操作,产量低,劳动强度大,卫生条件差,成品包装简陋甚至无包装。为了适应现代社会对食品的需要,传统的米粉条正逐步走向生产工业化,食用方便化,品种多样化,从小作坊进入工厂。研究米粉条加工的发展进程,工艺技术的关键,存在的问题,发展方向,对推进这一传统食品的发展,有着深远的意义。减速器是许多机械设备传动机构的重要部件之一,其性能的好坏与用户的经济效益及社会效益有着密切的关系,此文的减速器的设计包括,V型皮带轮的设计,斜齿圆柱齿轮的设计,主轴的设计,减速器箱体的设计,箱体的密封与润滑,以及减速器内各种标准零件的选择,其中包括轴承的选择,由于减速器的稳定性对安全生产的影响,所以应提高减速器的稳定性。

关键字:减速器,皮带轮,斜齿圆柱齿轮,主轴,密封,润滑,稳定性。

The JN-A rice noodle pushes the silk machine spare part design

Abstract:The rice noodle production all is continues to use the traditional process and the manual operation, the output is low, the labor intensity is big, the hygienic condition is bad, the end product packing crude does not even have the packing.In order to adapt the modern society to food need, the traditional rice starch noodles are moving to wards the production industrialization gradually, the edible convenience, the variety diversification, the workshop enters the factory since childhood.The research rice starch noodles processing development advancement, the processing technology key, the existence question, the development direction, to advances this traditional food the development, has the profound significance.Reduction gear is one of important machine equipment in transmission organ. Whose function goodness and badness have close relation to consumer`s economic effect and social benefits.The design of reduction gear in article include those,Those are design of v-pulley,design of helical gear, design of shaft,design of reduction case,sealing and slip of case,and chooseing kinds of criteria sections in reduction gear,therein include shaft bearing,because the stability of reduction gear must enhance as much as influence stability of reduction gear on security of work.

Key words :Reduction gear , pulley ,helical gear ,shaft ,sealing ,slip ,stability .

米粉挤丝机机的减速部分的设计

设计要求

要使米粉挤丝机成功生产出米粉,减速器中熟化轴的转速要达到 rpm,挤丝轴的转速 rpm,减速器的使用年限为十年,生产率为90-110kg/h.

#p#副标题#e#

目录

摘要 3

1.绪论 5

1.1前言 6

1.2熟化原理 7

1.3挤压加工原理 7

1.4工艺要求 8

2.米粉挤丝机机的减速部分的设计 9

2.1设计要求 9

2.2设计内容 9

2.2.1传动装置的总体设计 9

2.2.2传动零件的设计计算 10

2.2.3轴的设计 18

2.2.4各轴健的选择与计算 25

2.2.5滚动轴承的选择 25

2.2.6箱体的设计 26

2.2.8减速器附件的选择 26

2.2.9减速器润滑方式,密封形式,润滑油牌号及用量的简要说明 27

3.铜螺母并帽的设计 27

3.1材料的选择 27

3.2结构的设计 27

4.挤丝后筒的设计 28

4.1材料的选择 28

4.2结构的设计 28

参考文献 29

致 谢 30