X700涡旋式选粉机的设计(转子部件)

无需注册登录,支付后按照提示操作即可获取该资料.

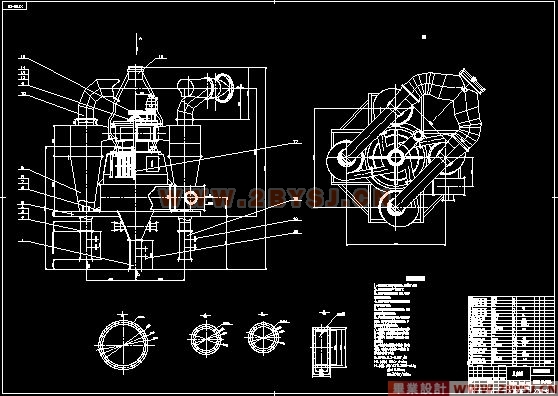

摘 要:为了满足现代水泥企业越来越高的生产要求,本课题完成X700涡旋式选粉机的子部件设计及改进。本次设计采用理论设计和经验设计相结合的方法,首先在分析以往的转子式选粉机优缺点的基础上再通过类比设计设计出能够提高分级力场的笼型转子,吸取o-sepa选粉机的优点采用导风装置提高涡旋效果。笼型转子与导风装置配合使用使物料均匀受到分级力的作用提到选粉效率。其传动系统采用带轮传动。其传动故障率较低,维修及更换零件方便。转子由耐磨钢片和盖板组成,中部盖板成环型均布70个长方形孔。钢片穿过中盖板方孔焊接,以保证其稳定性。转子下部加装倒锥体,起加固转子加强上升气流。撒料装置放在转子上部采用耐磨铸件批量生产,节约成本,采用螺栓连接,维修方便。改变以往耐磨衬板耐磨方式,采用贴耐磨瓷砖方法。其耐磨效果好且成本低。轴与轴套之间采用油浴润滑,提高润滑效果。经过设计改造后的选粉机大大减少了运行成本,提高了生产效率达到能耗低、易维修的效果。

关 键 词:涡旋式选粉机;笼型转子;分级力;选粉力场;撒料盘。

The design of X700 eddy type powder selecting machine (the design of rotor parts)

Abstract : In order to satisfy requirements of modern cement enterprise more and more high production, this topic designs and improves X700 eddy type powder selecting machine. This design adopts the method which combine theories design with experience design. First, at the base of analyze advantages and disadvantages of the former rotor type of machine, the cage rotor which can enhance the graduation field of force is designed by analogy method. Refering advantages of o-sepa powder selecting machine air ducting is used to enhance the eddy effect. The combination of cage rotor with air ducting cause the material evenly to absorb the graduation force so that the powder efficiency has been improved. Its transmission system adopts belt pulley transmission, because leather belt transmission is low in failure transmission, convenient in service and adjustment. The rotor is consisted of wear-resisting steel piece and lap, around the middle of the lap has seventy holes. The steel piece goes through the lap and welding with the lap, to guarantee its stability. The board under the rotor install conical body gets up reinforces the rotor to strengthen the ascendant current. The material scatters installment made of the wear-resisting casting volume production put it on top of the rotor, saves the cost, uses the bold fastening, convenient in service. Use the wear-resisting ceramic tile instead of the formerly board wear-resisting way. The wear-resisting has good effect、lower in cost. Between the axis and the axle sleeve seals uses the bath lubrication, enhances the lubrication effect. After the process transformation make the machine reduce the movement cost greatly ,enhanced the production efficiency, achieved high efficiency in choosing the powder, low in energy consumption, convenient in service.

Key words: eddy type powder selecting machine; cage rotor; graduation strength; graduation field of force; material scatters.

本课题是进行X700涡旋式选粉机转子部件设计及改造。以往的选粉机结构存在一些不是很合理的地方,且其选粉效率一直受到限制,不是很高。通过本课题的一些设计改进,以达到令人满意的效果 。

本课题的来源和技术要求:

a.本课题的来源:在使用传统转子式选粉机的水泥企业的生产过程中,发现了很多转子式选粉机的缺点和不足,选粉效率低功耗大满足不了现在的企业需求。本课题的设想是经过一些改造,改进其原本的缺点,提高效率,尽量满足水泥企业的需要。

b.技术要求:所有结构及其零部件设计后考虑技术性、加工工艺性、经济性,并保证安装、使用、经济方便。要保证选粉机的运转平稳,节能高产。

本课题要解决的主要问题和设计总体思路:

a. 本课题解决的主要问题:首先原来的转子不能提供稳定的分级力场,不能提供稳定的分级力,进料受力不均影响选粉效率影响产量。原先的耐磨衬板成本高,安装维修困难,且增大整机的重量给运输造成不便。原先的转子式选粉机涡旋效果不理想选粉效果不佳。撒料盘易损坏,零件更换成本高且单件制作成本较高。原先的润滑方式费用高,操作不便。

b. 本课题的设计总体思路:减速器传动虽然易磨损,零件更换成本高,但其传动比较平稳。换成皮带传动,因为其传动比比较大,一级传动肯定是不行,所以这里采用二级皮带传动,电机采用立式电机,并用焊接架支撑在顶盖上。内部改造部分: 首先采用笼型转子,提高分级力场的稳定性。轴与轴套之间密封采用油浴室润滑,降低费用操作方便。撒料盘放在转子上部,增大物料下落过程的选粉几率。采用旋风筒增强选粉效果提高选粉效率。

预期的成果及其理论意义

通过对选粉机转子部件的设计改造,可以有效地降低成本,提高生产时间利用率,提高选粉效率,从而达到增加经济效益的目的。

目 录

1 前言……………………………………………………………………………1

1.1本课题的来源和技术要求…………………………………………………………1

1.2本课题要解决的主要问题和设计总体思路………………………………………1

1.3预期的成果及其理论意义………………………………………………………1

2 国内外发展状况及现状的介绍…………………………………………………….2

2.1离心式选粉机的发展与改进…………………………………………………….2

2.2旋风式选粉机的发展与改进………………………………………………………2

2.3转子式选粉机的发展与改进…………………………………………………….3

3总体方案论证……………………………………………………………………….5

4具体设计说明……………………………………………………………………….6

4.1工艺参数……………………………………………………………………………6

4.2连接轴的结构设计…………………………………………………………………7

4.3转子部件的设计………………………………………………………………… 14

4.4润滑系统设计…………………………………………………………………….16

(优秀毕业设计:www.2bysj.cn)

4.5螺栓组设计……………………………………………………………………….17

5结论………………………………………………………………………………….21

参考文献……………………………………………………………………………22

致谢………………………………………………………………23

附录……………………………………………………………………24

附 录

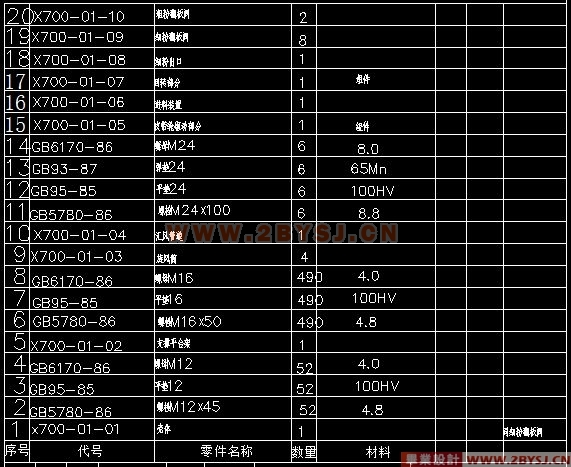

序号 图名 图号 图幅

1 总装图 X700 A0

2 转动件 X700-14 A1

3 透盖一 X700-14-2-1 A3

4 透盖二 X70014-2-2 A3

5 主轴 X700-14-2 A3

6 撒料盘 X700-14.3-8 A3

7 挡料板 X700-14-3-7 A3

8 密封环 X700-14-3-4 A4

9 密封圈 X700-14-3-5 A4

10 转子 X700-14-1 A2

11 轴套 X700-14-3 A2

12 导风装置 X700-8 A2