复合固体超强酸S2O82-/Fe2O3/ZnO催化合成乙酸异戊酯

无需注册登录,支付后按照提示操作即可获取该资料.

复合固体超强酸S2O82-/Fe2O3/ZnO催化合成乙酸异戊酯(论文8400字,外文翻译)

摘 要

乙酸异戊酯是没有颜色的,常温下是液体,并且澄清通明,它不与水相溶,但是由于相似相容原理,它能和一些有机溶剂相溶。人们主要用它作为一种溶剂,也用它来调味,制造皮革,制作绞盘等,在纺织业中,它可以用来做人造丝以及其它一些纺织品。不仅如此,我们平常用到的香皂或者一些合成的洗涤剂中香精的原材料,它在食用香精中的应用更加广泛,很多果香型香精都是用乙酸异戊酯来调配的。现在我们用乙酸与异戊醇酯化可以制备乙酸异戊酯,但是这个方法必须以浓硫酸作为制备条件。不仅如此,这种方法有很多问题,比如会造成设备的腐蚀、副产物比较多、很难进行后面的一些处理、酸性废水排放量大等。

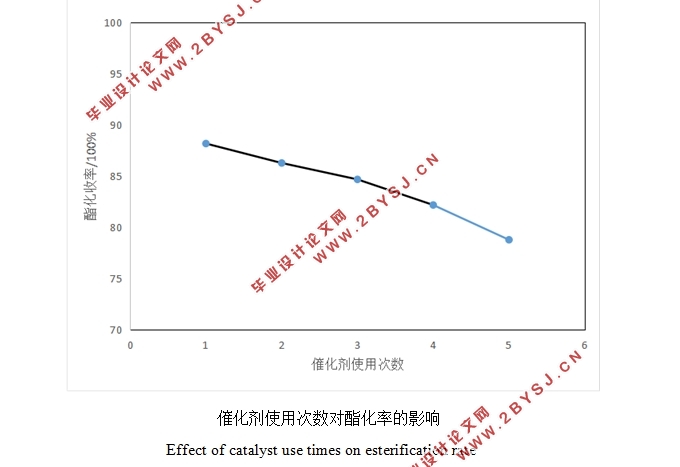

本实验是以固体超强酸S2O82-/Fe2O3/ZnO为催化剂,用异戊酯和冰乙酸为原料合成了乙酸异戊酯,探究了不同反应条件对乙酸异戊酯的酯化率的影响。结果表明,最佳的实验条件是:醇酸摩尔比为2:1,加入催化剂的质量为1g,反应的温度在120℃左右,反应的时间为50min左右,固体超强酸催化剂的煅烧温度在650℃左右的时候,酯化率最高,可以达到88.2%。这个实验方法的优点有很多,比如酯化率非常高,对环境友好,不污染环境,不会对设备造成腐蚀,催化剂可以重复使用等。

关键词:固体超强酸;催化;乙酸异戊酯; 酯化反应

Synthesis of Iso Amylacetate with Composite Solid Super Acid Catalyst

Abstract

Isoamyl acetate is colorless, a liquid at room temperature, and clear, it is not soluble in water, but because of the similar compatibility principle, it is soluble in some organic solvents. It is used primarily as a solvent, but also for flavoring, for making leather, for making capstan, etc. In the textile industry, it can be used to make rayon and other textiles. Not only that, we usually use soap or some synthetic detergent in the essence of raw materials, it is more widely used in the use of edible flavor, many fruit-flavor flavor iso-amyl acetate to mix. Now we can prepare iso-amyl acetate by esterifying acetic acid with iso-amyl alcohol, but this method must use concentrated sulfuric acid as the preparation condition. Not only that, this method has a lot of problems, such as will cause corrosion of equipment, more by-products, it is difficult to carry out some of the later treatment, acid wastewater emissions, and so on.

In this experiment, solid superacid S2O82-/Fe2O3/ZnO was used as catalyst to synthesize iso-amyl acetate with iso-amyl ester and glacial acetic acid as raw materials, and the effects of different reaction conditions on the esterification rate of iso-amyl acetate were investigated. Results show that the best experiment condition is: alcohol acid molar ratio of 2:1, join the quality of the catalyst is 1 g, the reaction temperature about 120 ℃, the reaction time is about 50 min, the solid superacid catalyst calcination temperature about 650 ℃, the esterification rate is the highest, can reach 88.2%. This experimental method has many advantages, such as very high esterification rate, environmentally friendly, does not pollute the environment, will not cause corrosion to the equipment, catalyst can be reused.

Key Words: solid superacids; Catalysis; Isoamyl acetate;esterification reaction

目 录

摘 要 I

Abstract II

第一章 文献综述 1

1.1 乙酸异戊酯 1

1.2 酯的合成方法 1

1.2.1 质子酸催化合成法 1

1.2.2 酰氯酯化法 2

1.2.3 酸酐酯化法 2

1.2.4 Mitsunobu反应 2

1.2.5 Steglich酯化法 3

1.2.6 DBU催化法 3

1.2.7 Me3SiCl催化法 3

1.2.8 羧酸盐与卤代烃反应法(相转移催化法) 3

1.3 固体超强酸的优点 3

1.3.1 固体超强酸介绍及优点 3

1.3.2 目前对固体超强酸的研究 4

1.4 固体超强酸的应用 5

1.5 研究内容 6

第二章 实验部分 7

2.1 仪器及试剂 7

2.1.1 仪器 7

2.1.2 药品和试剂 7

2.2 催化剂的制备 7

2.3 酯化反应的操作步骤 8

第三章 实验结果与分析 9

3.1 吸附影响条件 9

3.1.1 醇酸摩尔配比对酯化率的影响 9

3.1.2 反应温度对酯化率的影响 10

3.1.3 反应时间对酯化率的影响 11

3.1.4 催化剂的用量对酯化率的影响 12

3.1.5 不同煅烧温度的催化剂对酯化率的影响 13

3.1.6 固体超强酸催化剂的重复使用率 13

3.2 产品分析与表征 15

第四章 结论 16

参考文献 16

致谢 19