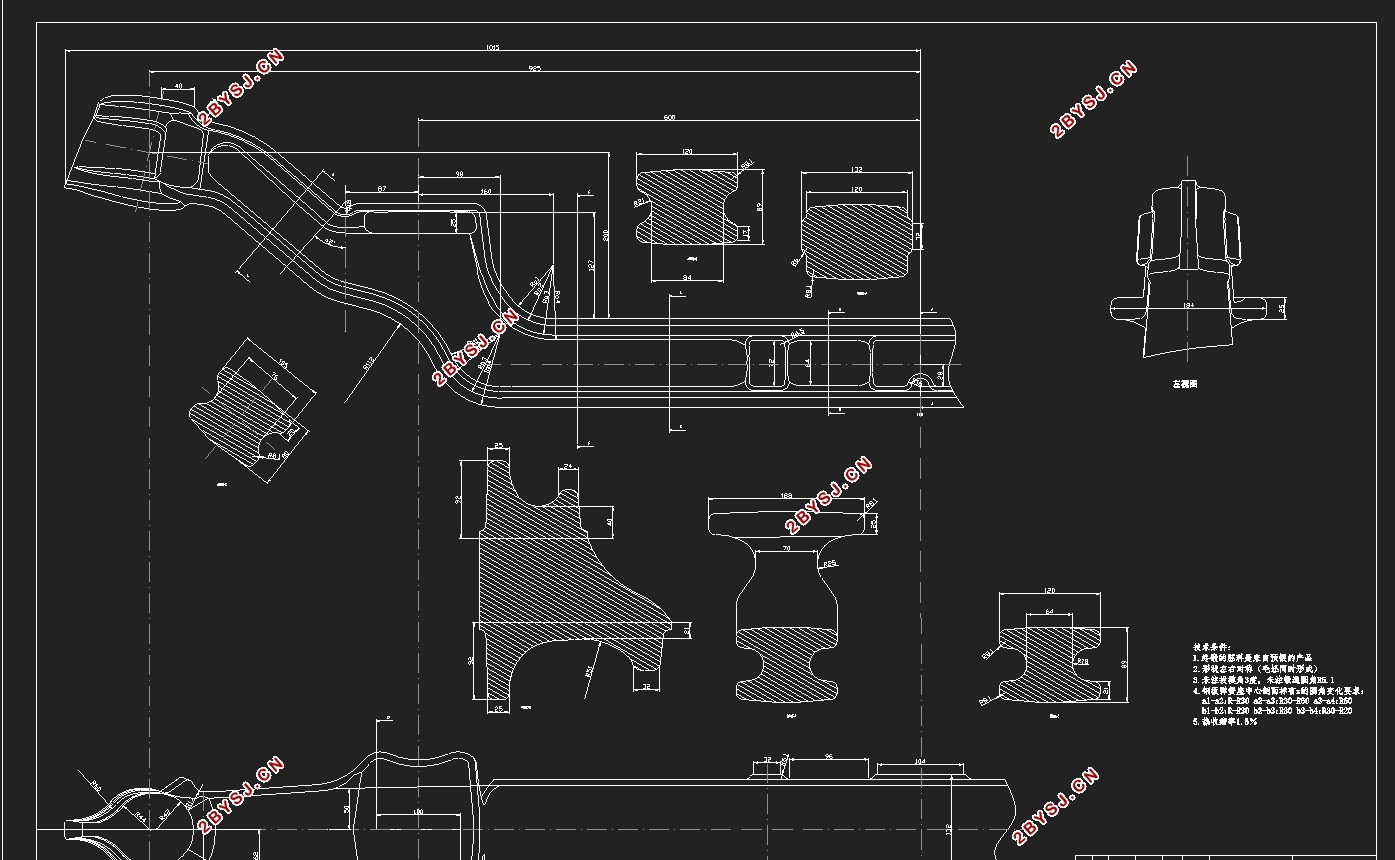

某汽车前轴锻件锻造工艺设计与仿真分析(含CAD图,CATIA三维图)

无需注册登录,支付后按照提示操作即可获取该资料.

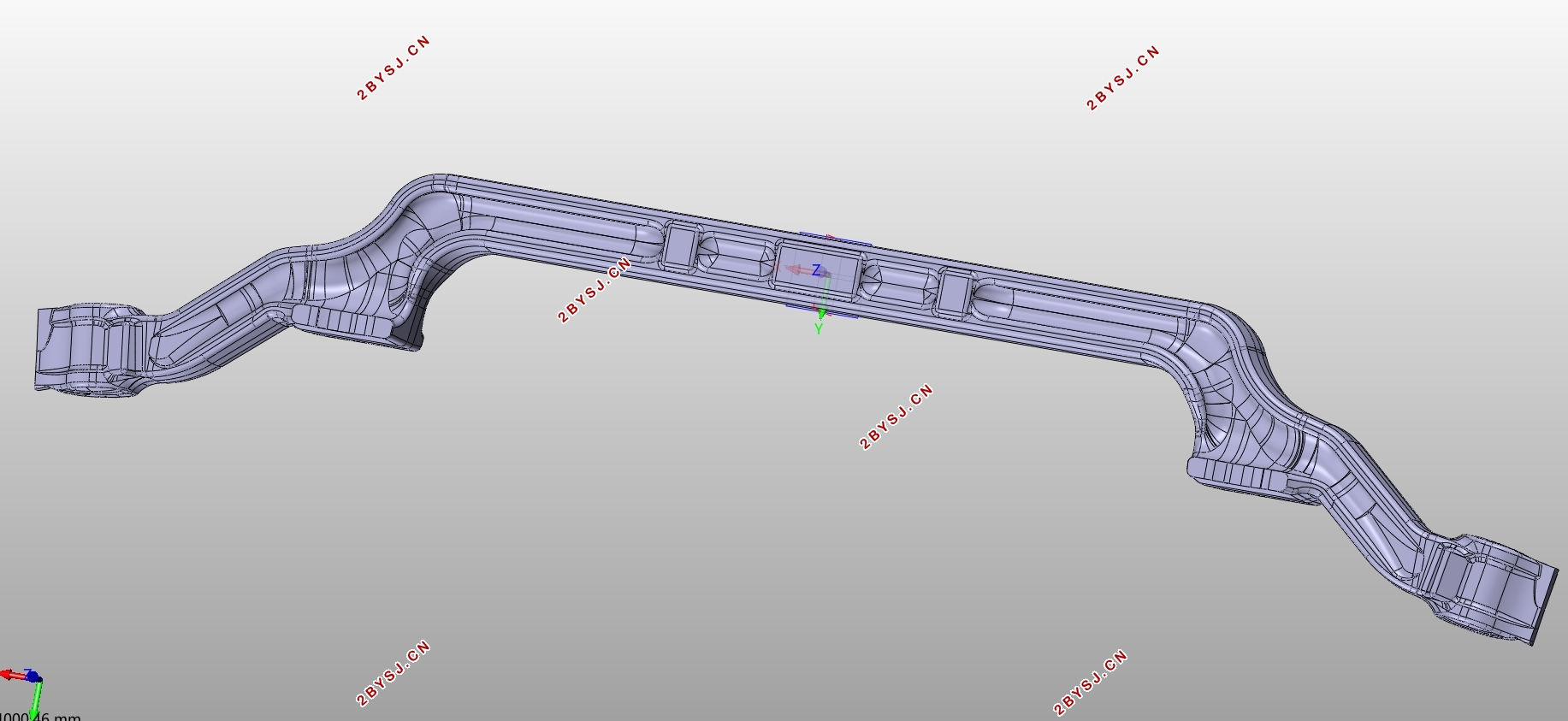

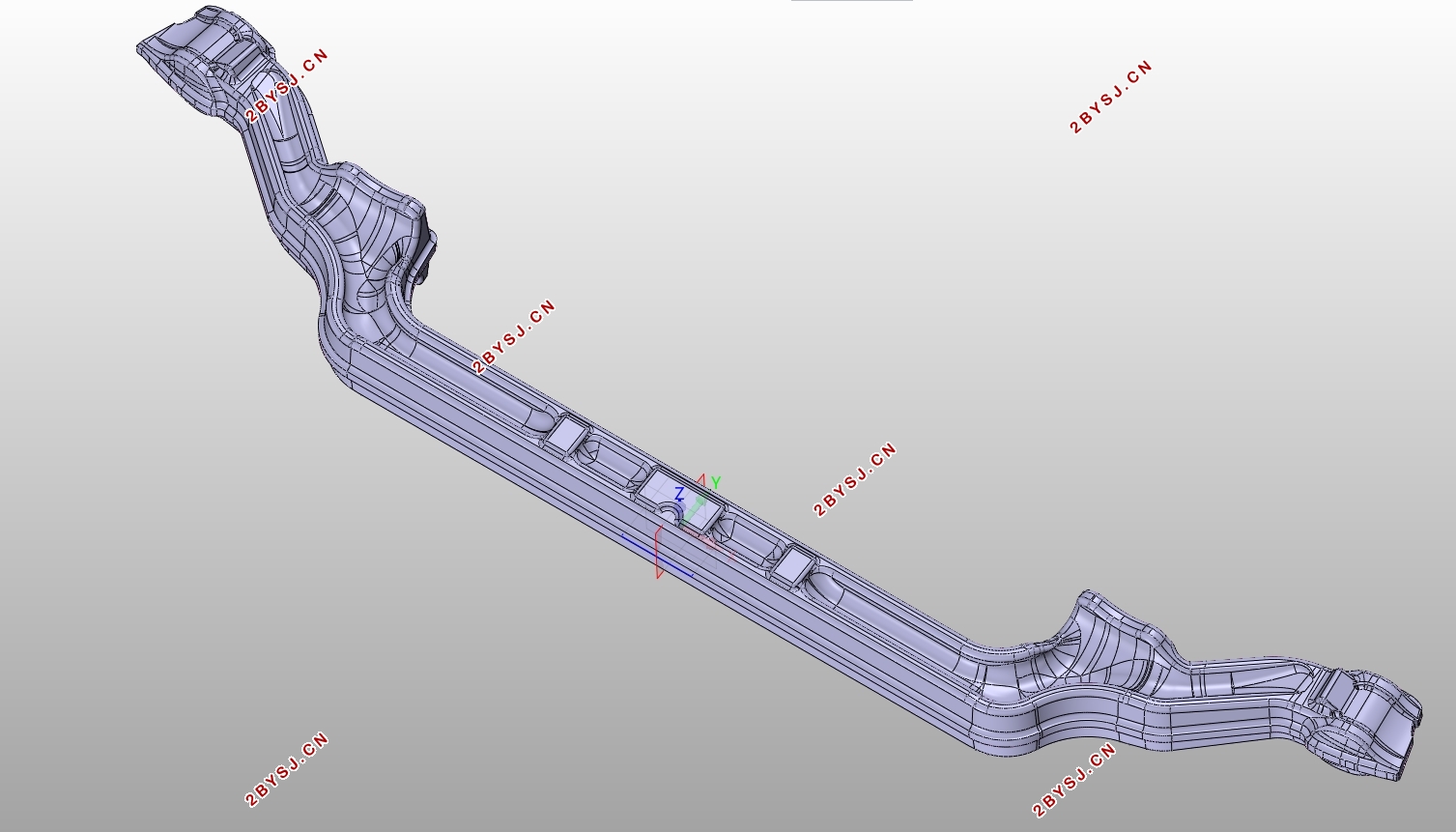

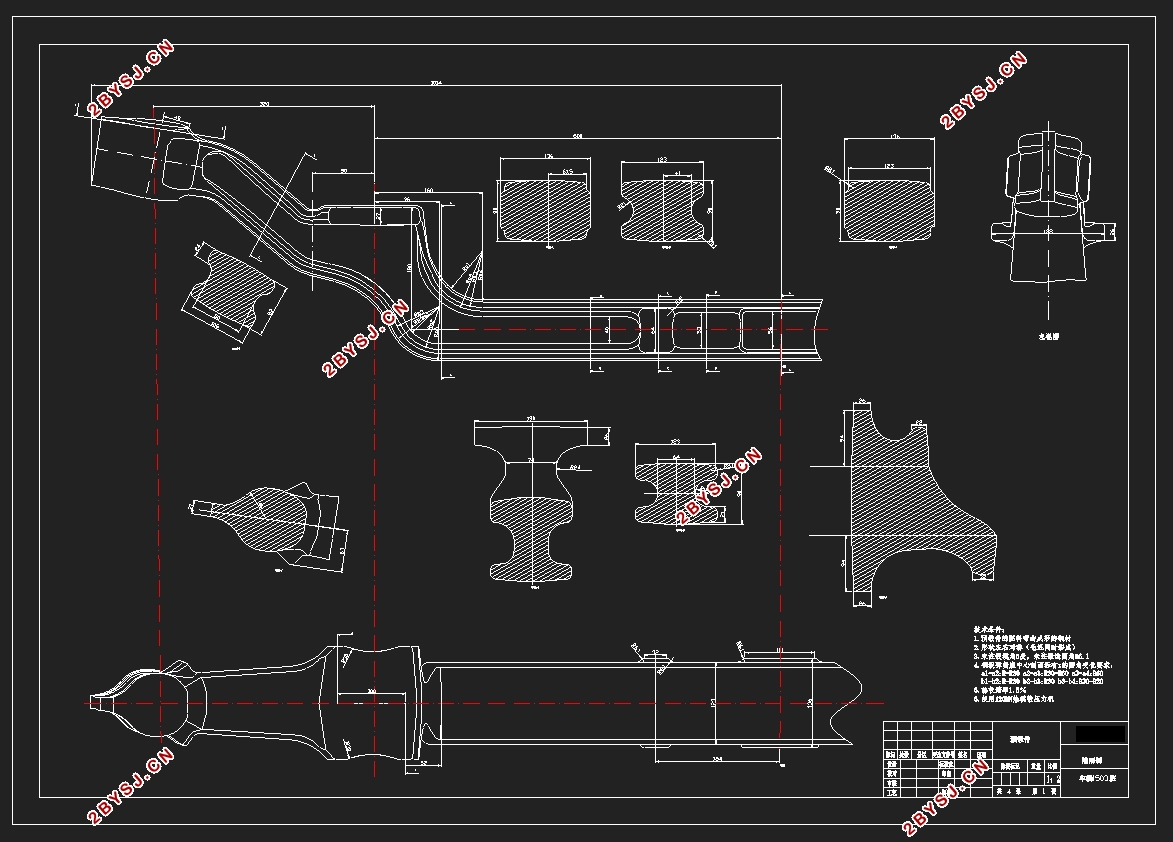

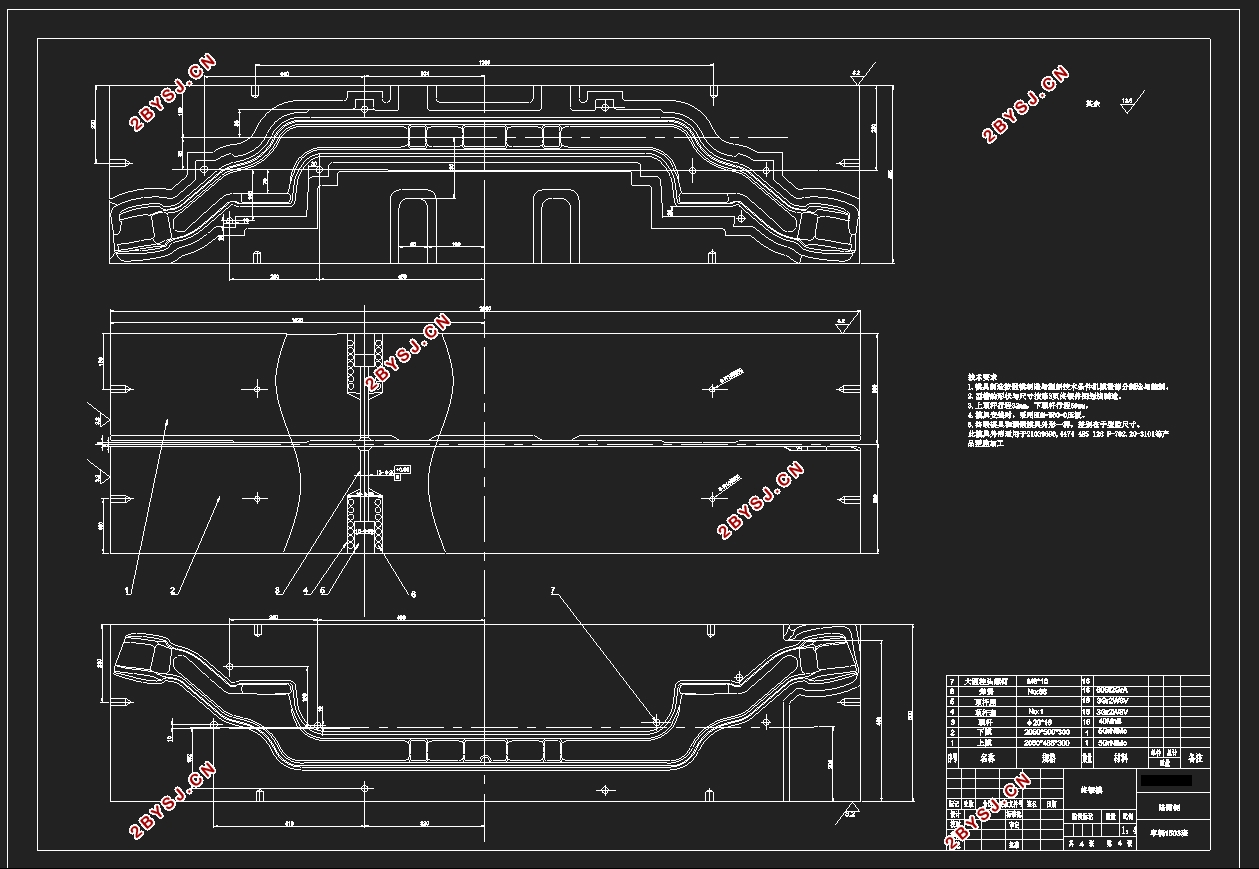

某汽车前轴锻件锻造工艺设计与仿真分析(含CAD图,CATIA三维图)(任务书,开题报告,论文说明书11300字,CAD图纸4张,CATIA三维图)

摘要

汽车是当今社会必不可少的交通工具,其产业是世界上最大、最主要的产业之一,前景可观。而汽车前轴作为大型客车、货车重要的零部件之一,用于承受冲击性负荷。汽车前轴的结构繁杂、制造困难,一般用锻造工艺生产。模拟汽车前轴锻件的模锻过程,分析锻件潜在的缺陷,对锻件的锻造工艺进行优化处理,对于公司提高锻件质量、减少锻件的废品率有着重要的意义。

本文研究当前世界汽车产业的发展状况,各国锻造工艺技术研究背景和研究现状,分析各种锻造方案的优势和劣势以及面对不同锻件的时候如何进行选择。基于以上的研究,采用有限元分析软件DEFORM对某汽车前轴的整体终锻成形进行了锻造模拟。在本次设计中,针对不同的锻造工艺参数如锻造温度、锻造压力进行了多次仿真,最终得出结论:在相同锻造压力下,锻造温度越高,锻件受到的应力越小;在相同锻造温度下,锻造速度越小,锻件受到的应力越小。本次设计得到的最优锻造参数是,锻造温度1200℃,锻造速度40mm/s。本次设计还得出了锻造时模具受到的锻件热传递的最高温度和模具的应力变化图。本次设计为降低锻造成本,缩短锻造模具的设计周期,提高锻件质量提供了科学依据。

关键词:模具设计、锻造工艺、有限元、模拟仿真

Abstract

The automotive industry is one of the largest and most important industries in the world, and the prospects for the automotive industry are still very impressive.And the front axle of the car is one of the important parts of large passenger cars and trucks, and is used to withstand impact loads.The shape of the front axle of the car is complex, and the manufacturing is multi-purpose using a forging process.Simulating the die forging process of automobile front axle forgings, analyzing the potential defects of forgings, and optimizing the forging process of forgings, it is of great significance for the company to improve the quality of forgings and reduce the scrap rate of forgings.

This paper studies the development status of the current world automobile industry, the research background and research status of forging technology in various countries, analyzes the advantages and disadvantages of various forging schemes and how to choose when facing different forgings.On the basis of the above, the finite element analysis software DEFORM was used to simulate the forging of the integral forging of a car's front axle. In this design, several forging process parameters such as forging temperature and forging pressure were simulated several times. Finally, it was concluded that under the same forging pressure, the higher the forging temperature, the smaller the stress on the forging; in the same forging at the temperature, the smaller the forging speed, the less stress the forging receives. The optimum forging parameters obtained from the secondary design are a forging temperature of 1200 degrees and a forging speed of 40 mm/s. The design also yields the highest temperature of the forging heat transfer and the stress change of the mold during forging. This design provides a scientific basis for reducing the forging cost, shortening the design cycle of forging dies and improving the quality of forgings.

Key Words:moulddesign; forging process;finite element; simulation

2.1零件工艺性分析

运用CATIA三维造型软件建模,画出汽车前轴的三维结构,如图1.1所示。该汽车前轴采用的材质为AISI-1035。前轴铸件的基本轮廓尺寸为1854×120.8×92.5mm,锻件质量为150kg。前轴锻件属于杆类零件,外形结构长且大且繁杂、锻造成形要求高、生产难度大的锻件,需要用大型的热锻压力机(80MN或160MN)来模锻成型。锻件形状关于中心面对称,左右在较长部分不对称。

目录

目录 I

第1章绪论 1

1.1课题研究的背景及意义 1

1.2国内外研究现状 1

1.3课题研究内容与目标 2

第2章前轴锻造工艺设计 3

2.1零件工艺性分析 3

2.2前轴锻件锻造设计 3

2.2.1分模面的确定 3

2.2.2公差和加工余量 3

2.2.3确定模锻斜度 5

2.2.4圆角半径 5

2.2.5确定锻件热收缩率 6

2.3锻造模具的设计 6

2.3.1型腔的设计 6

2.3.2模具飞边槽确定 6

第3章有限元仿真 8

3.1有限元分析概念 8

3.2有限元仿真原理 8

3.2.1刚塑性有限元法基本假设 8

3.2.2刚塑性变分原理 9

3.3刚塑性有限元求解过程 9

第4章汽车前轴锻造过程的有限元仿真 10

4.1 DEFORM软件介绍 10

4.2 DEFORM仿真分析 11

4.2.1模拟方案设计 11

4.2.2模拟过程 12

4.3模拟结果分析 17

4.3.1锻造速度的影响 17

4.3.2锻造温度的影响 18

4.3.3模具的温度 20

4.3.4模具的受力 21

第5章总结与展望 23

参考文献 24

致谢 26